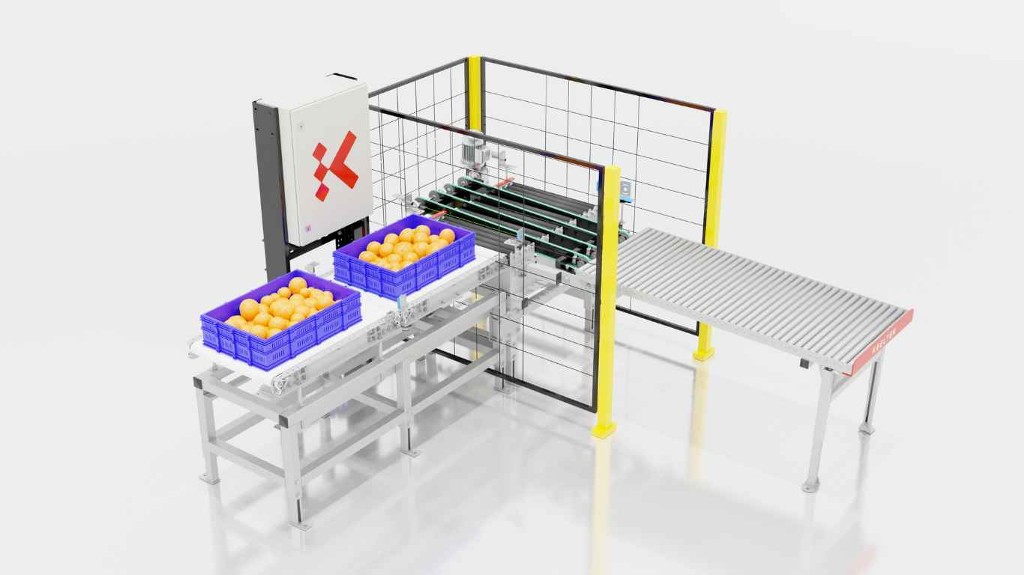

Feeding and transfer area

Mesh area

The "KOR robotic line for reinforcement" is a clear commitment to innovation in order to provide a tested technological solution, focused on an own need of the ceramic sector that is increasingly oriented towards XXL formats in the line, entirely developed by Keeltek, is designed from the outset taking into account maximum production efficiency and respect for the environment

MAIN FEATURES

ERGONOMICS AND ENVIRONMENT

Security for the Operators Management. (Secure handling of large formats)

Avoiding a curing system using gas burners (fossil combustion)

Emitting particles into the atmosphere through airbrush application systems have been stopped

Not using industrial paper in our process, cleaning and precising product application

*IR kiln (below photo 3)

BENEFITS

Compatible with different types of resins, monocomponents and bicomponents

Wide range of reinforcing meshes, fiberglass, carbon, polyester, and any gr/m²

Ceramic plate, porcelain, natural stone, sintered stone, marble

Pieces from 600mm x 600mm to 2000mm x 4000mm and maximum weight 500kg

Achievable rate up to 30 pieces/hour depending on the format used

System able of optimizing the consumption of applied product, achieving the highest possible performance

Adaptable to make sandwich

Allows transferring pieces from trestle to drawer and other way around

Fully automatic line

Technology 4.0. Ready

KTS ready support