Food and beverage

sector

Food and beverages

Solutions for the food and beverage

sector

Robust and flexible automation for a constantly evolving sector: unique solutions that improve the handling and management of parts in key stages of the manufacturing process, as well as in quality control and final palletizing.

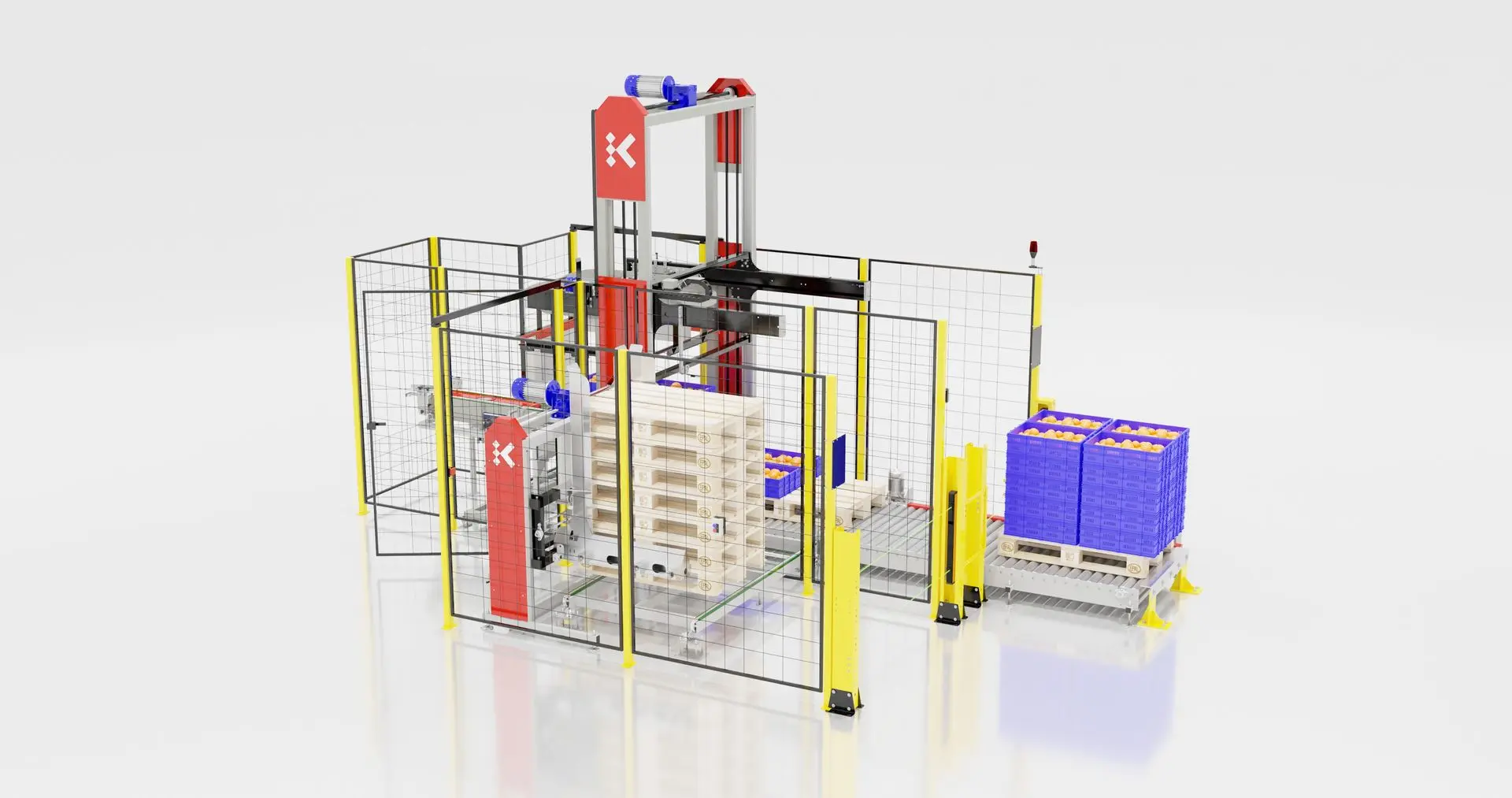

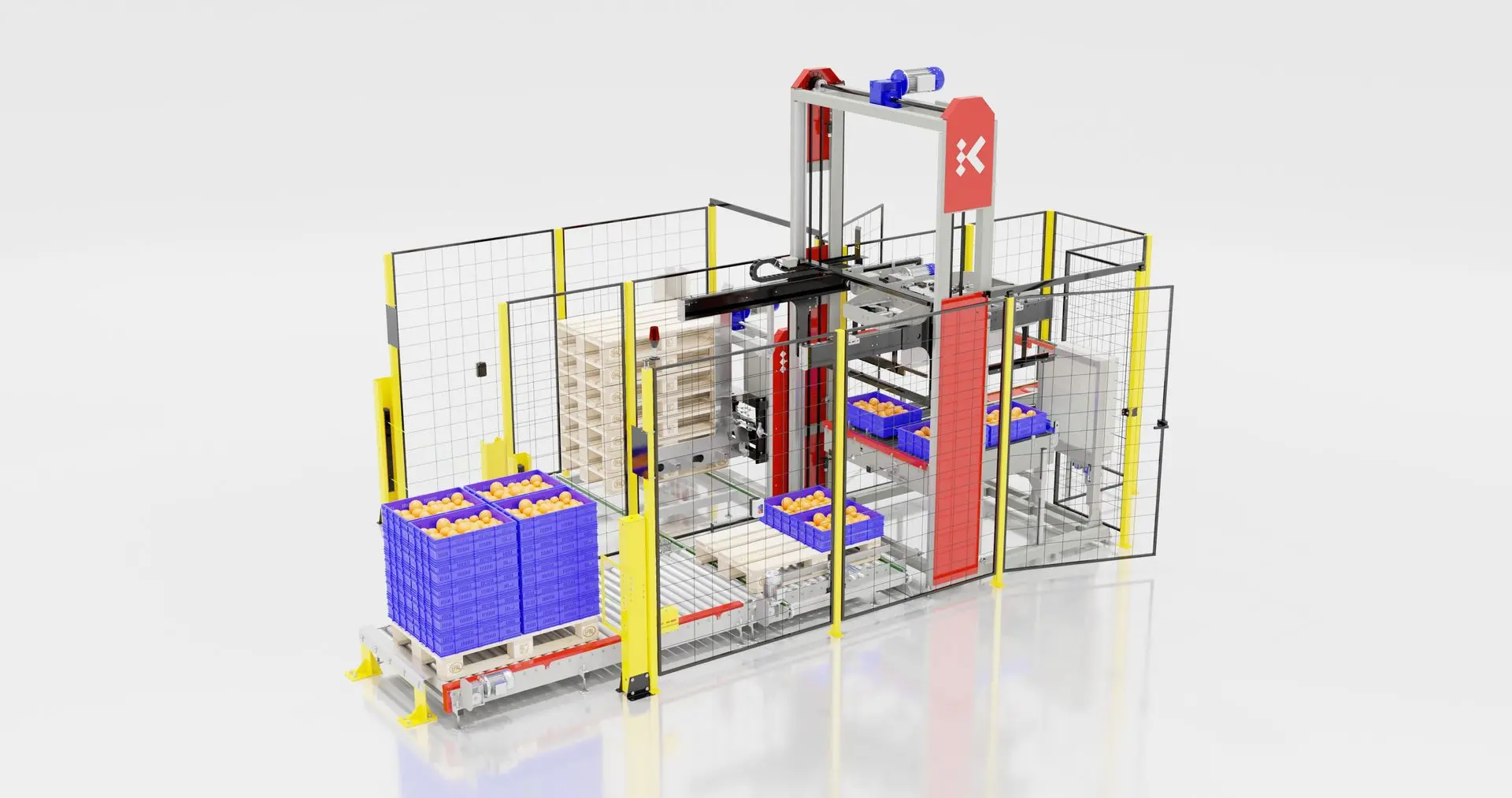

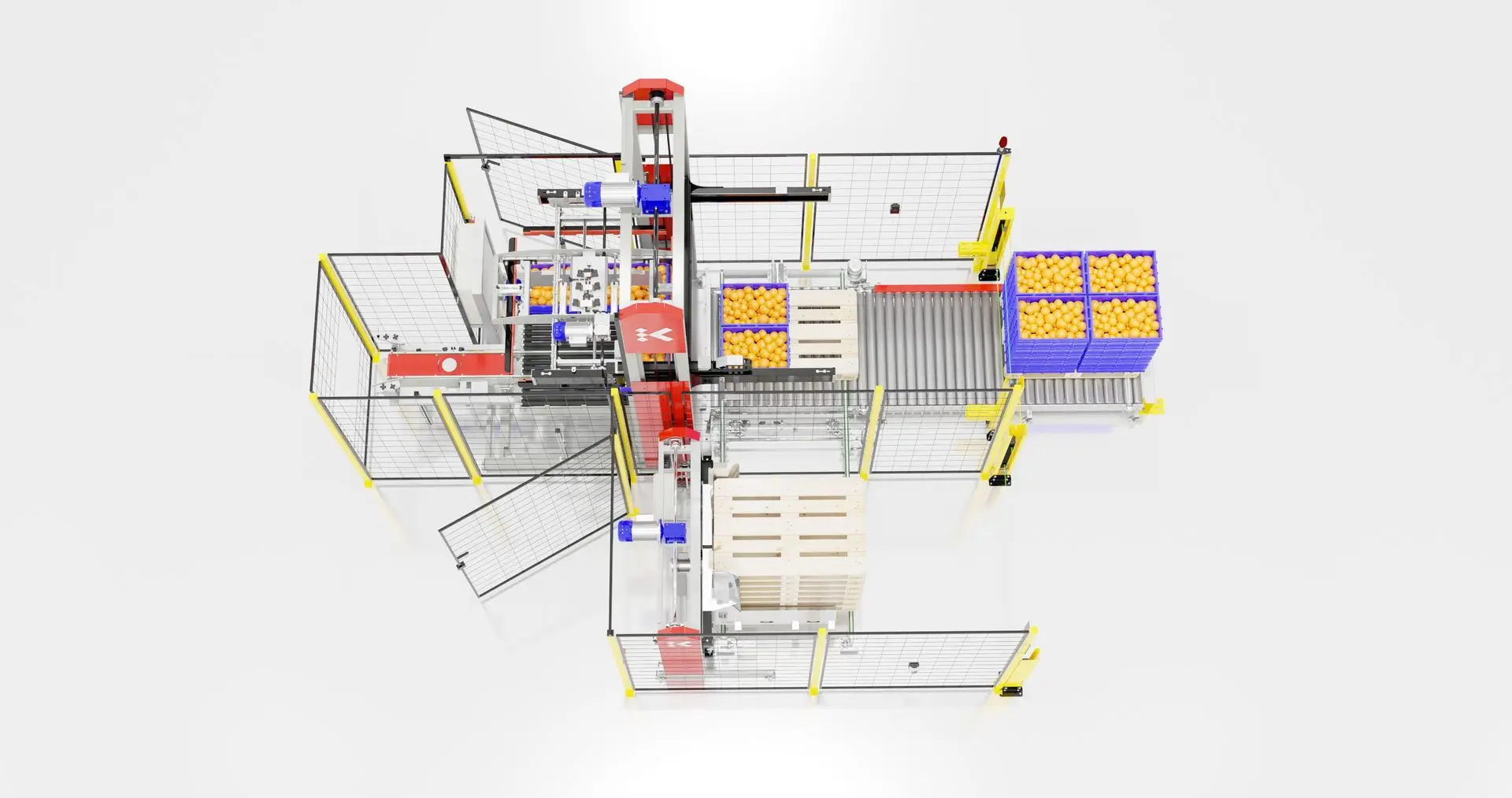

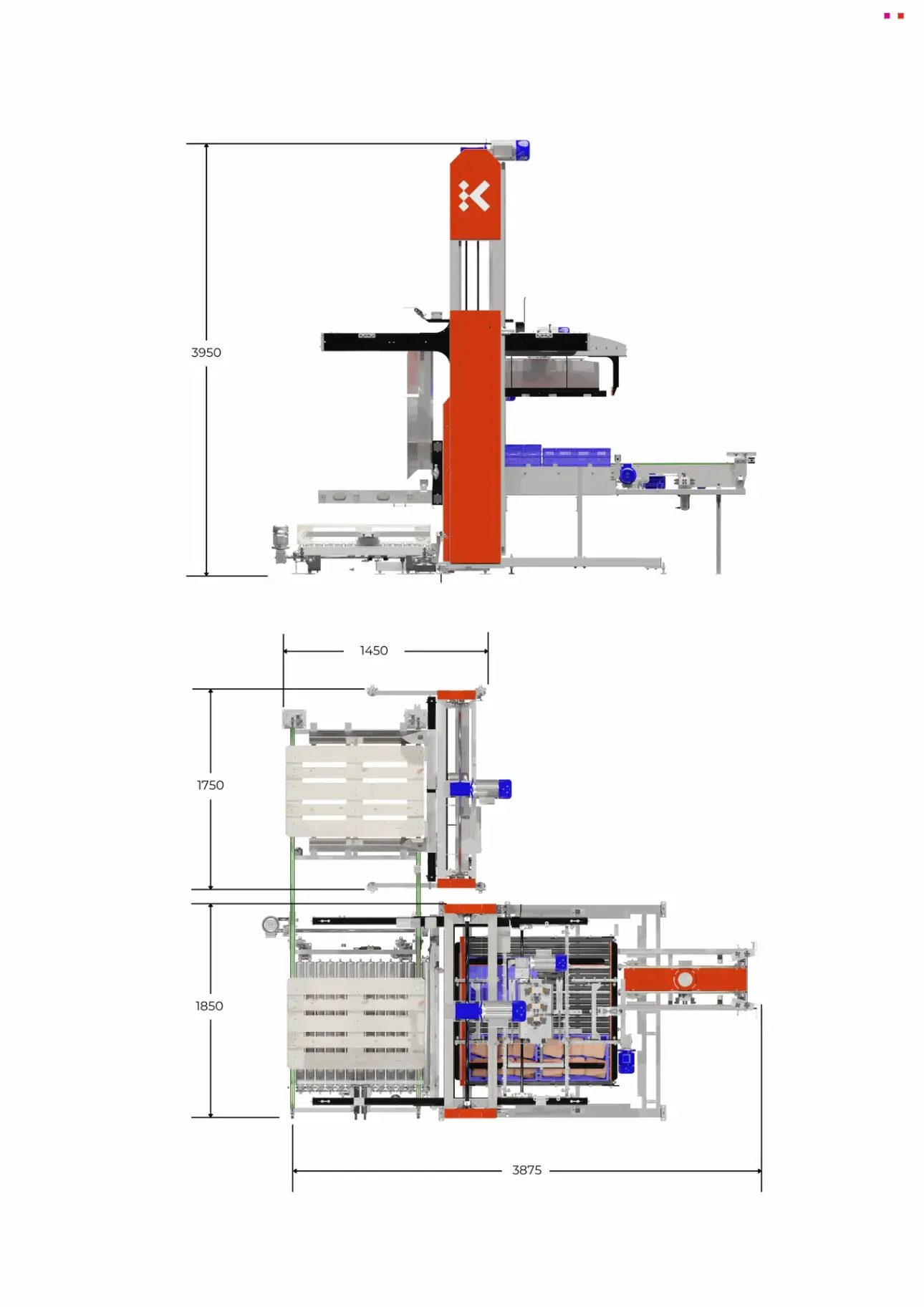

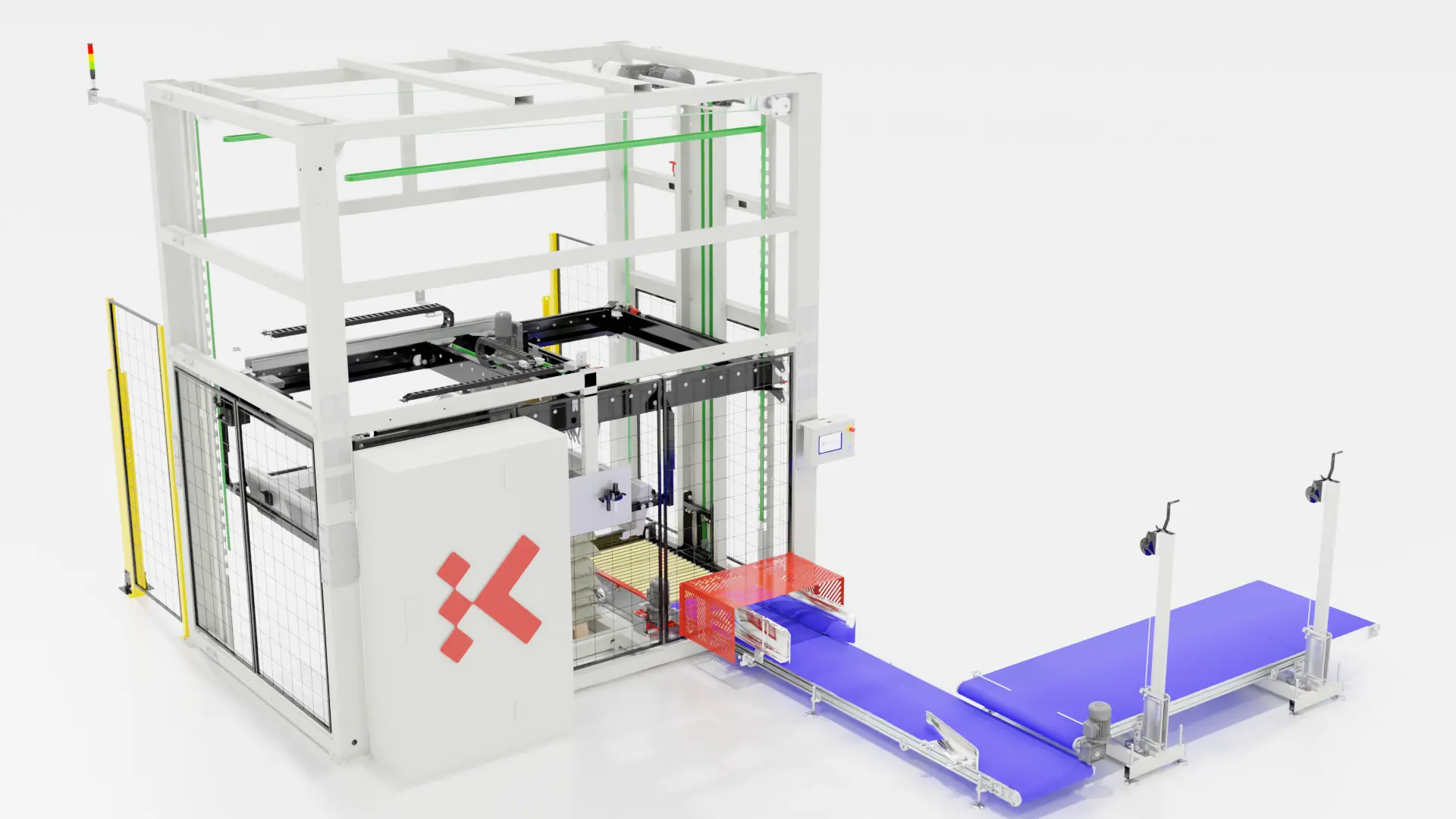

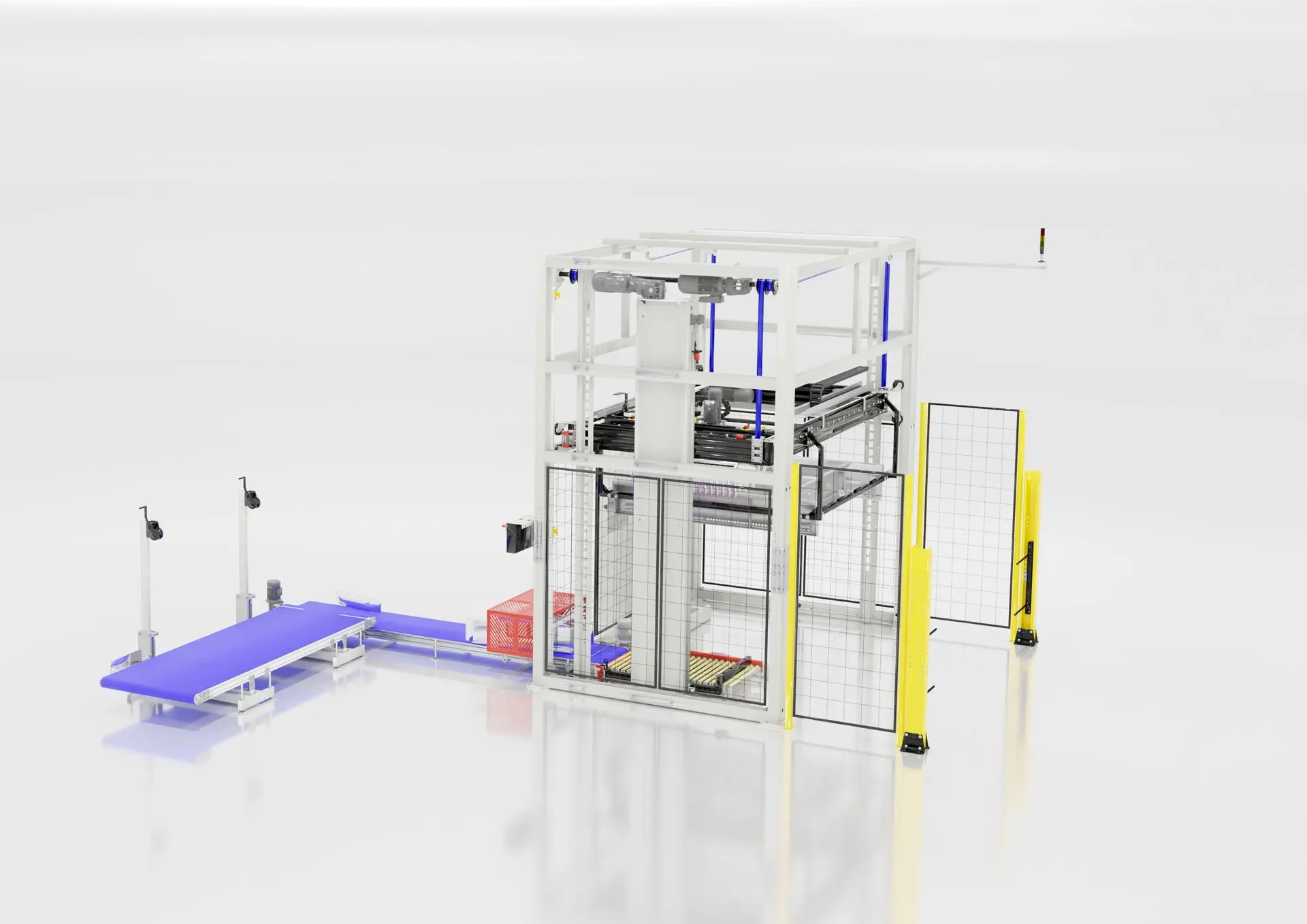

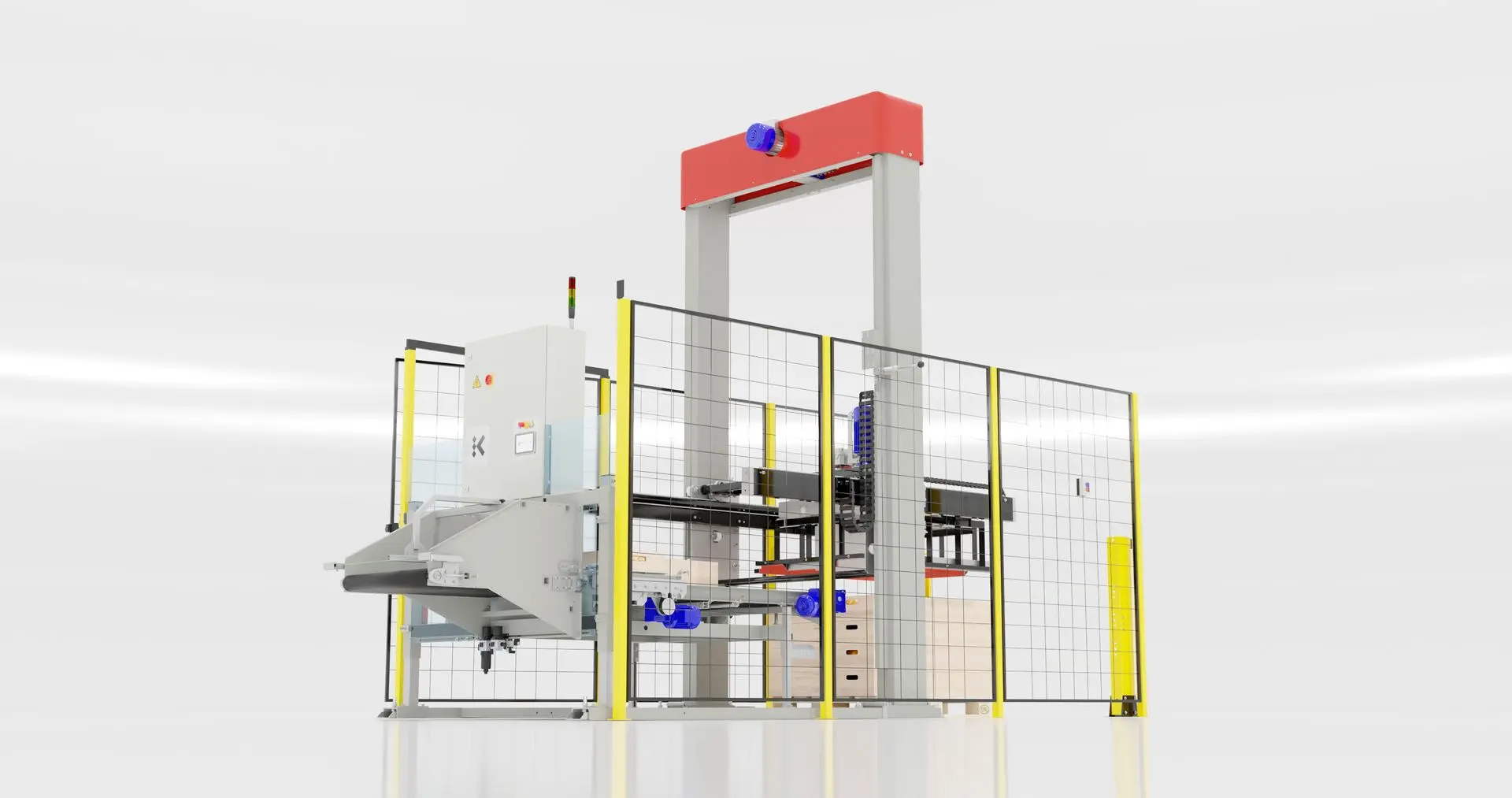

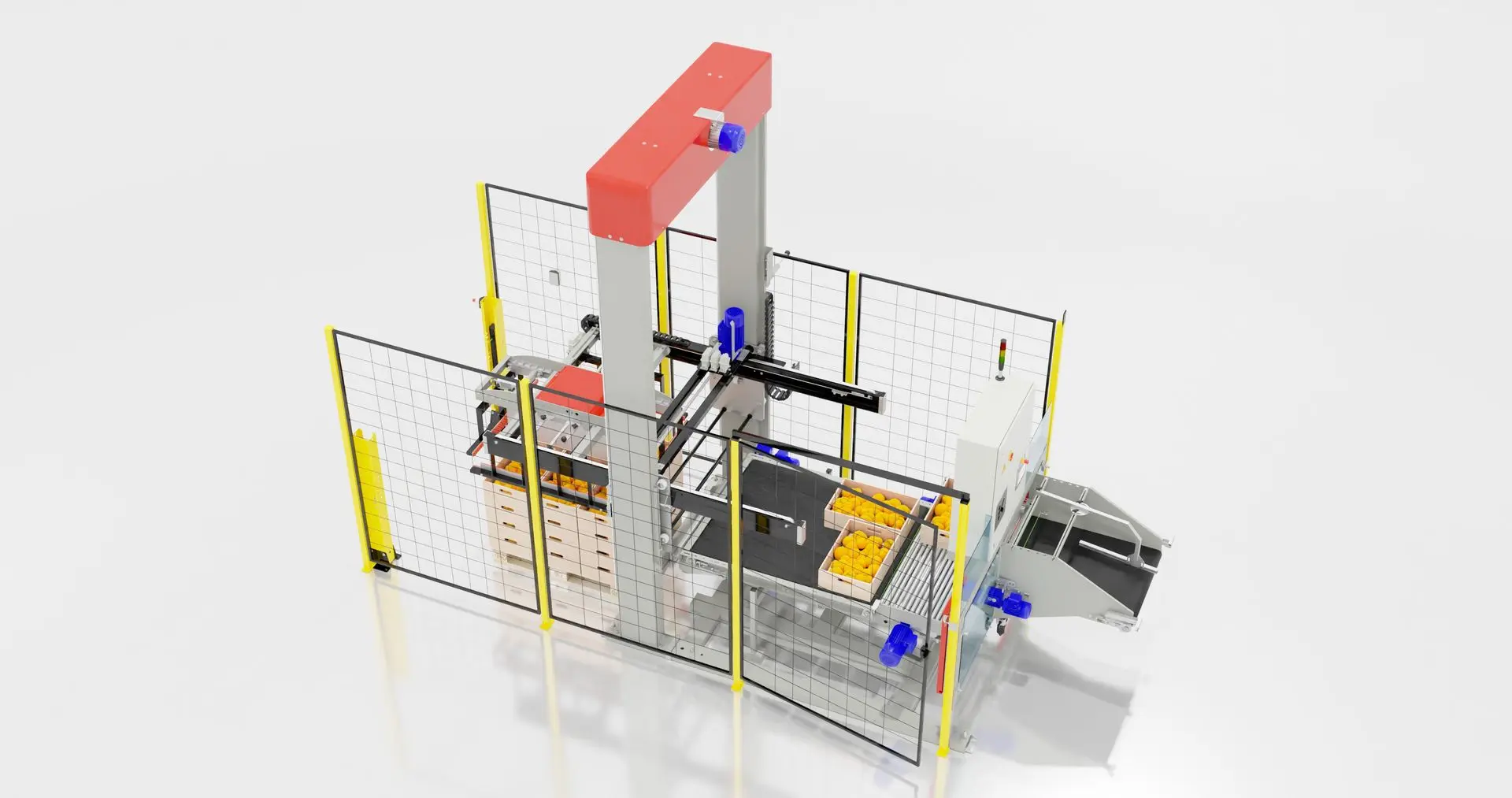

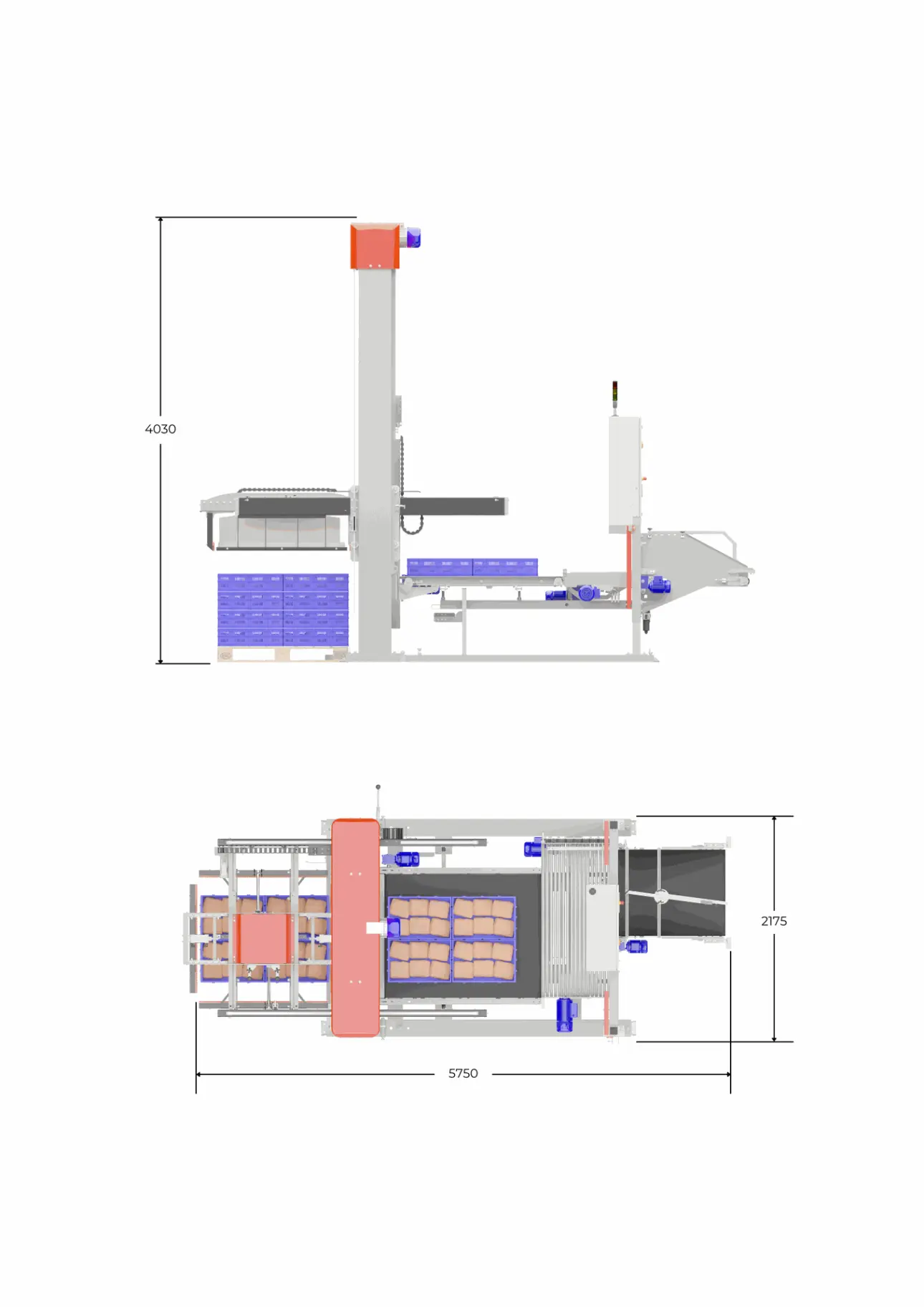

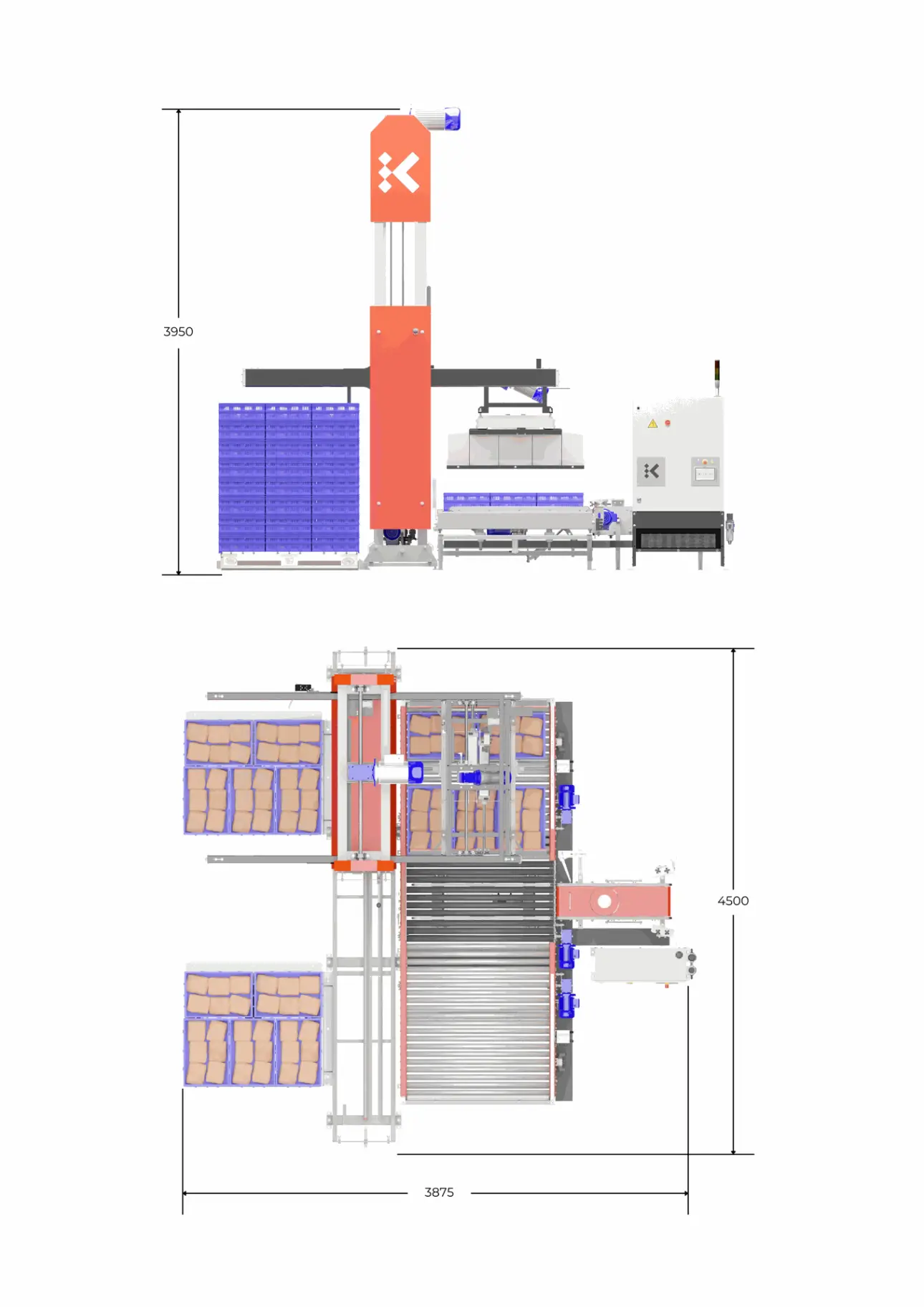

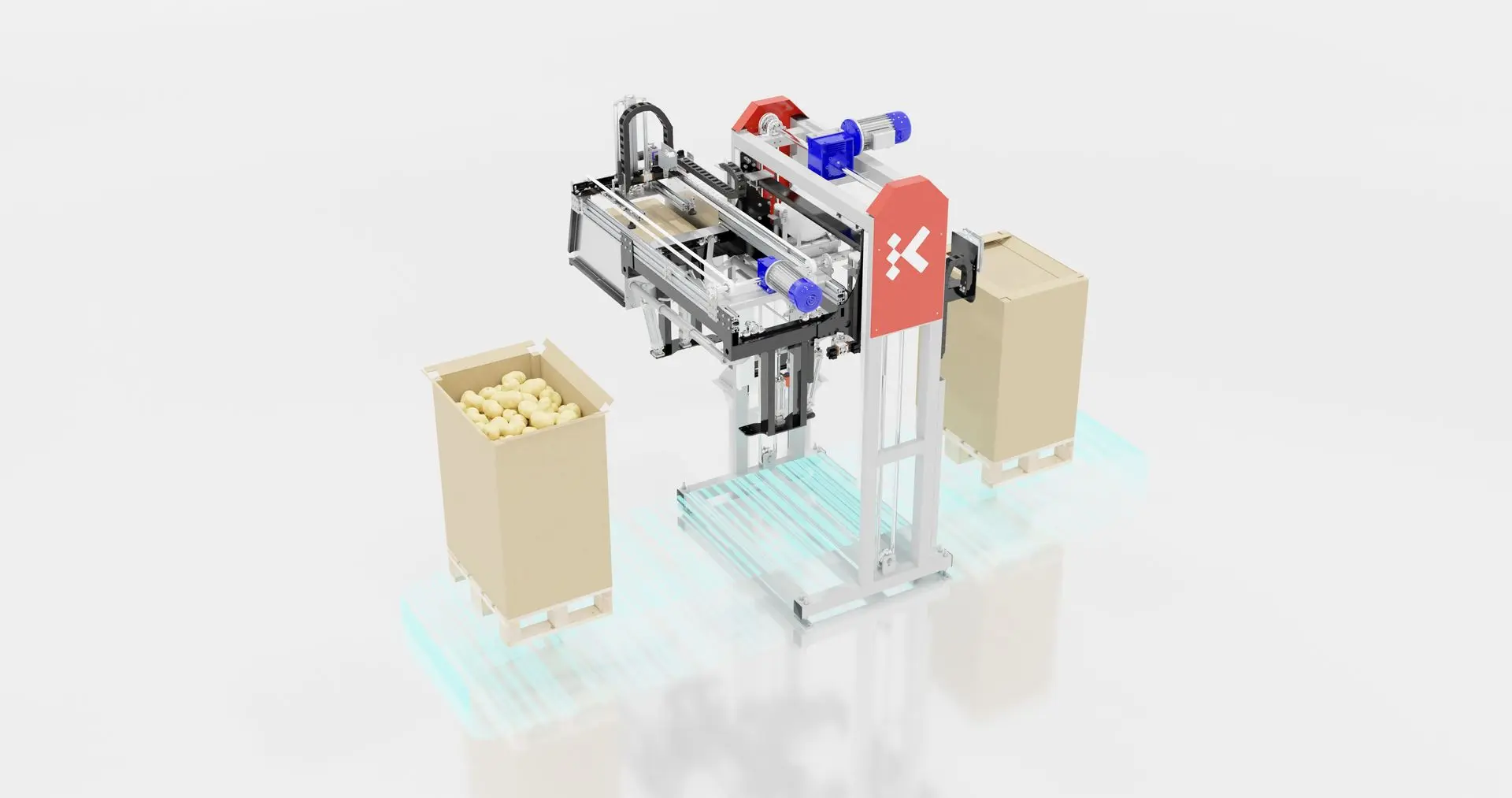

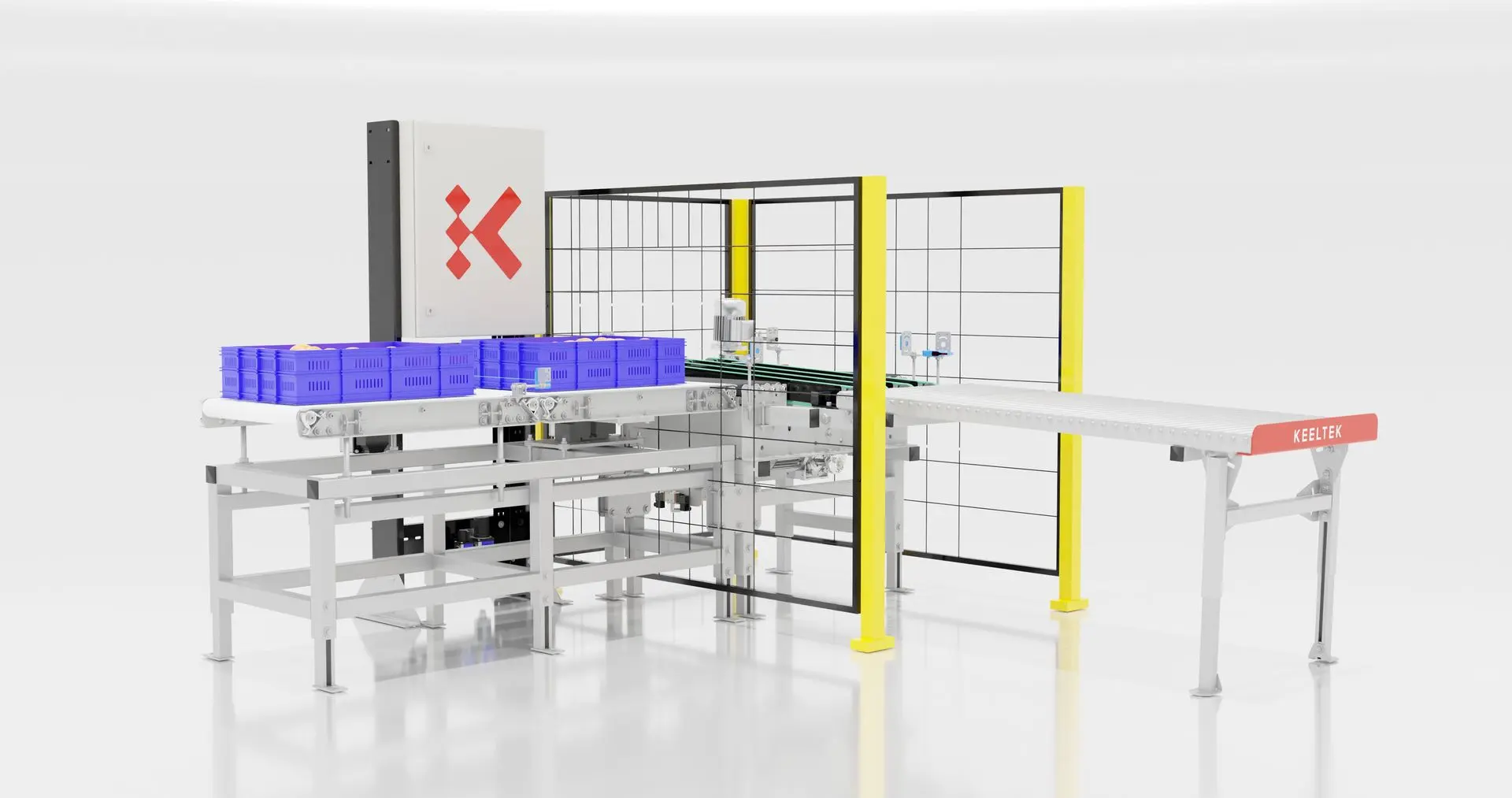

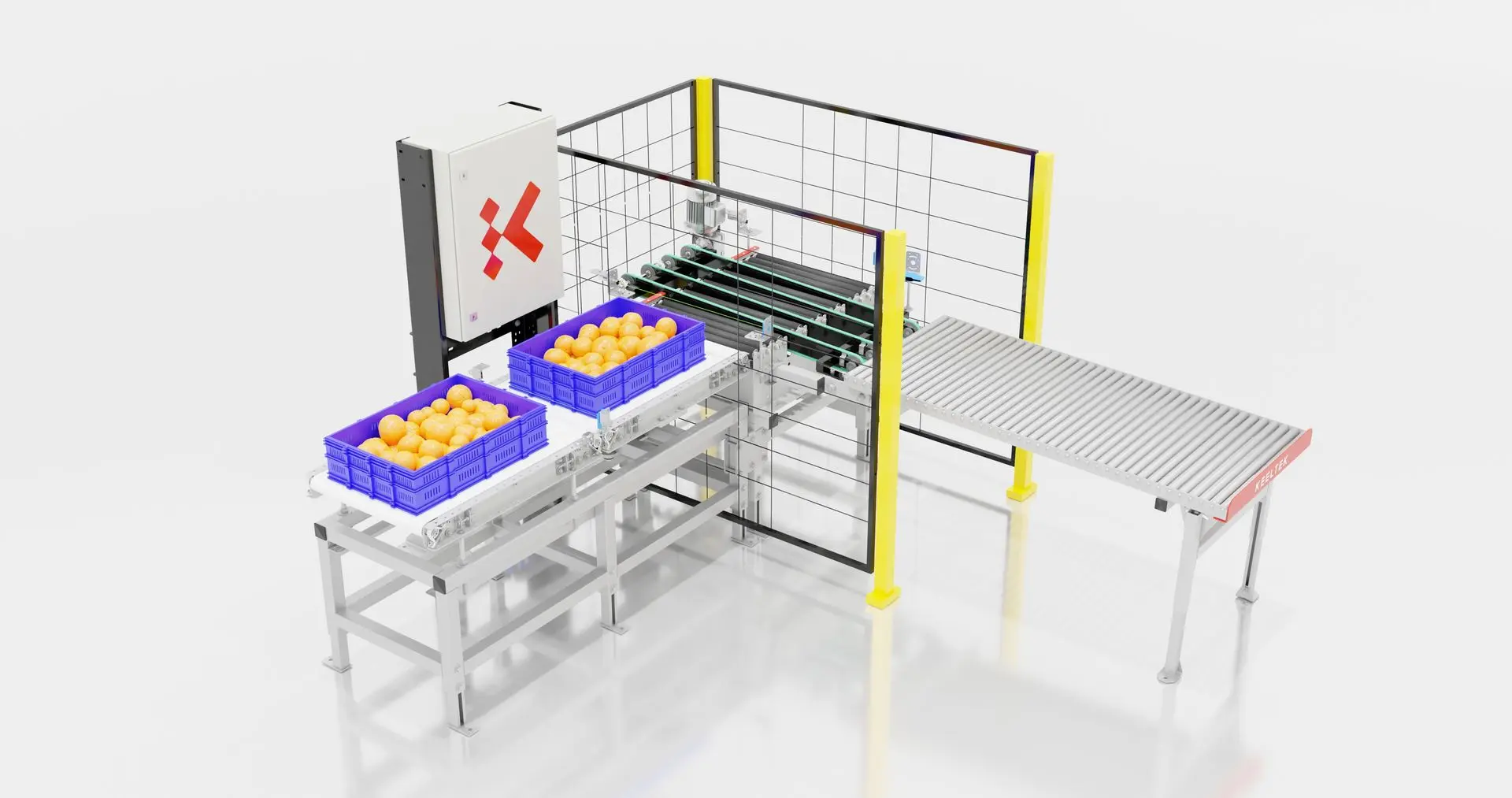

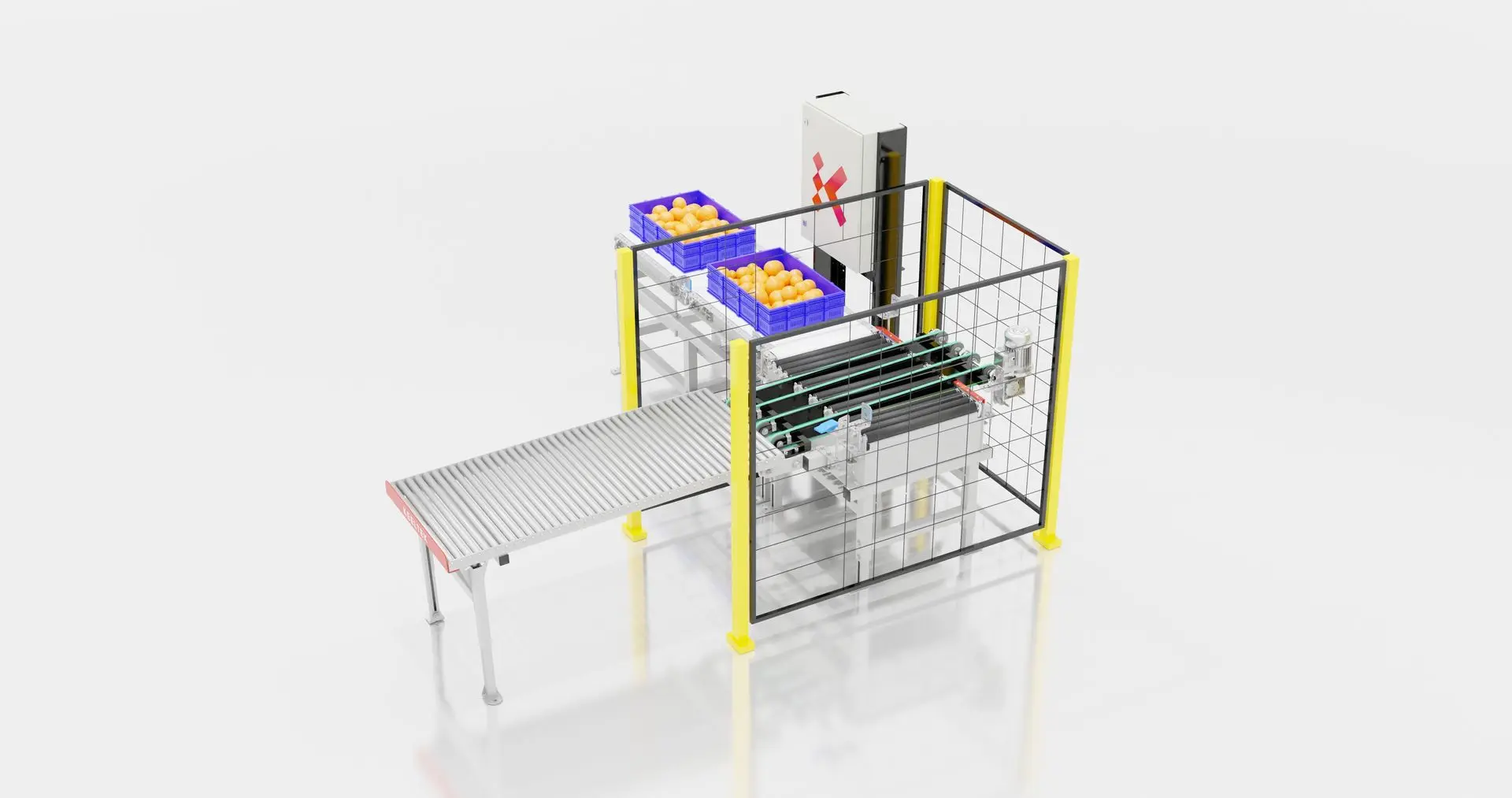

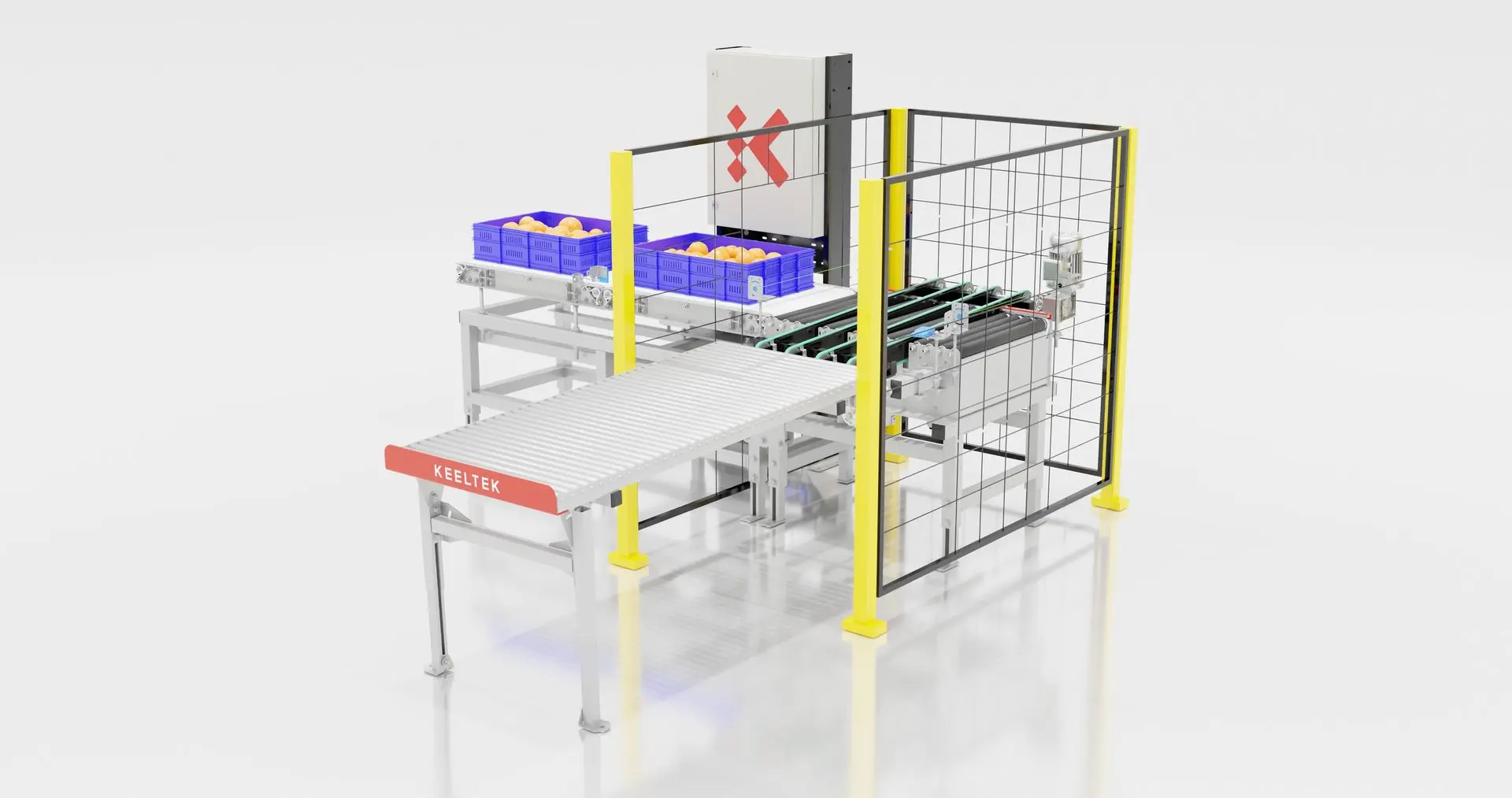

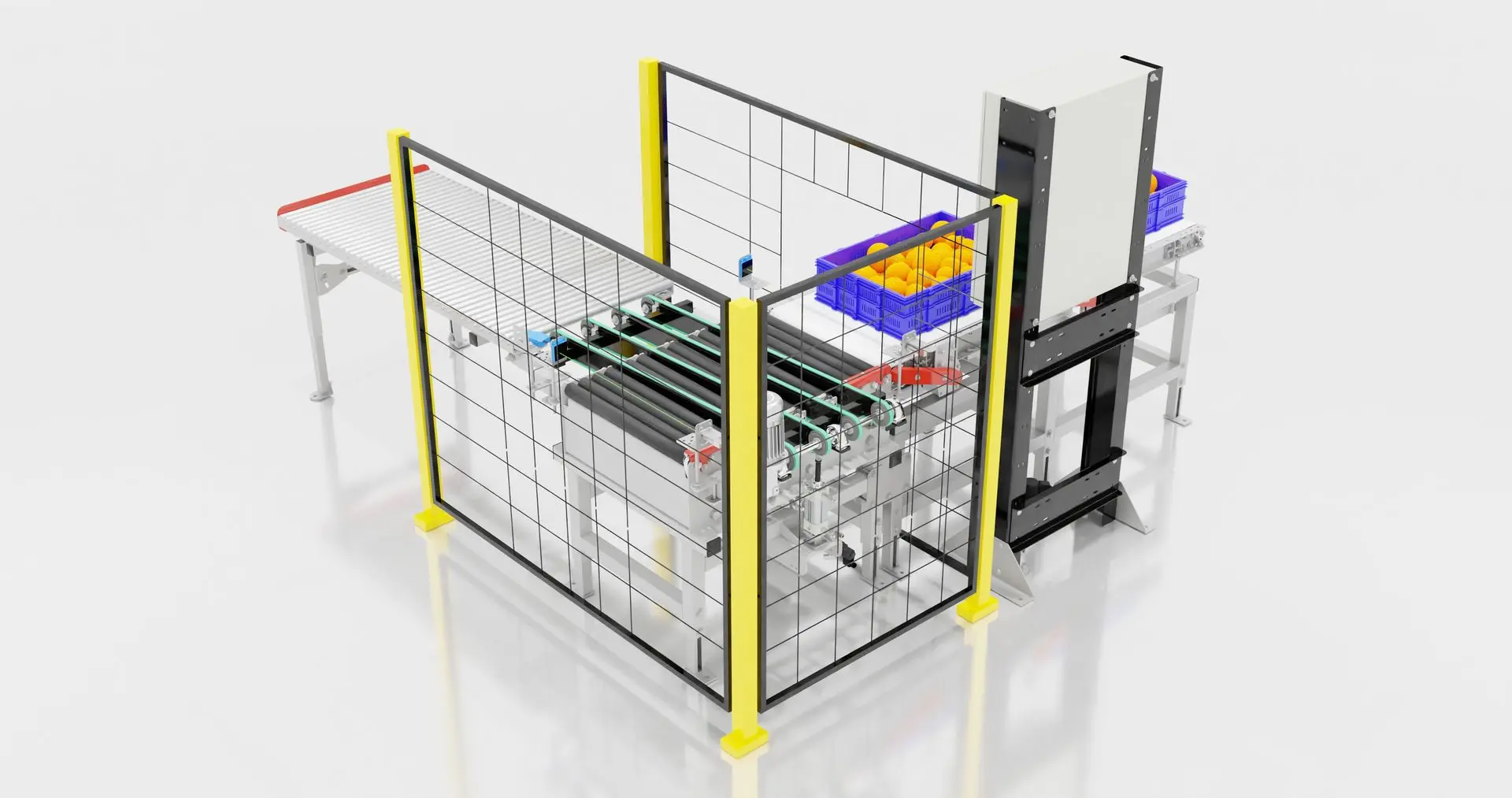

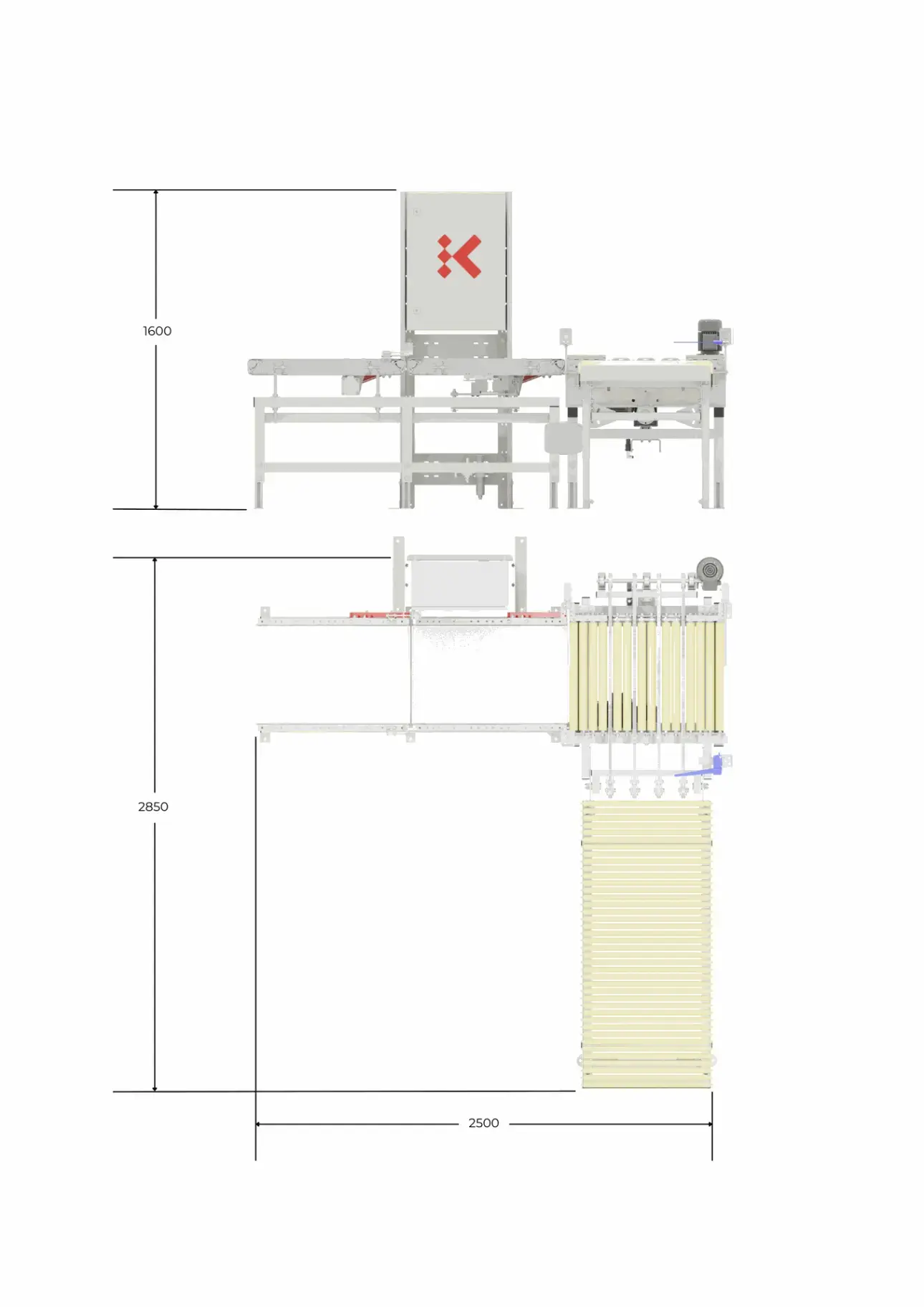

EASYPAL / EASYDEPAL

2-axis Cartesian palletizer by layers

2-axis Cartesian palletizer/depalletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing or depalletizing boxes in layers.

EASYPAL / EASYDEPAL

2-axis Cartesian palletizer by layers

2-axis Cartesian palletizer/depalletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing or depalletizing boxes in layers.

EASYPAL / EASYDEPAL

2-axis Cartesian palletizer by layers

2-axis Cartesian palletizer/depalletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing or depalletizing boxes in layers.

EASYPAL / EASYDEPAL

2-axis Cartesian palletizer by layers

2-axis Cartesian palletizer/depalletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing or depalletizing boxes in layers.

EASYPAL / EASYDEPAL

2-axis Cartesian palletizer by layers

2-axis Cartesian palletizer/depalletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing or depalletizing boxes in layers.

| Reference Product | Boxes of any size compatible with the pallet |

| Tiles | Any tile configuration |

| Maximum permissible load | Up to 175 kg. |

|

Connectivity

|

Industry 4.0 Ready |

| Cadences | Up to 3 shots per minute. |

Equipment | Rotator with selectable label positioning. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed using laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Labeling machine integration.

- Automatic pallet dispenser and changer.

- Reversed layer function for improved stability.

- Add pallet between layers function. (Manual or automatic).

- KTS, remote assistance.

- Full stainless steel finishes

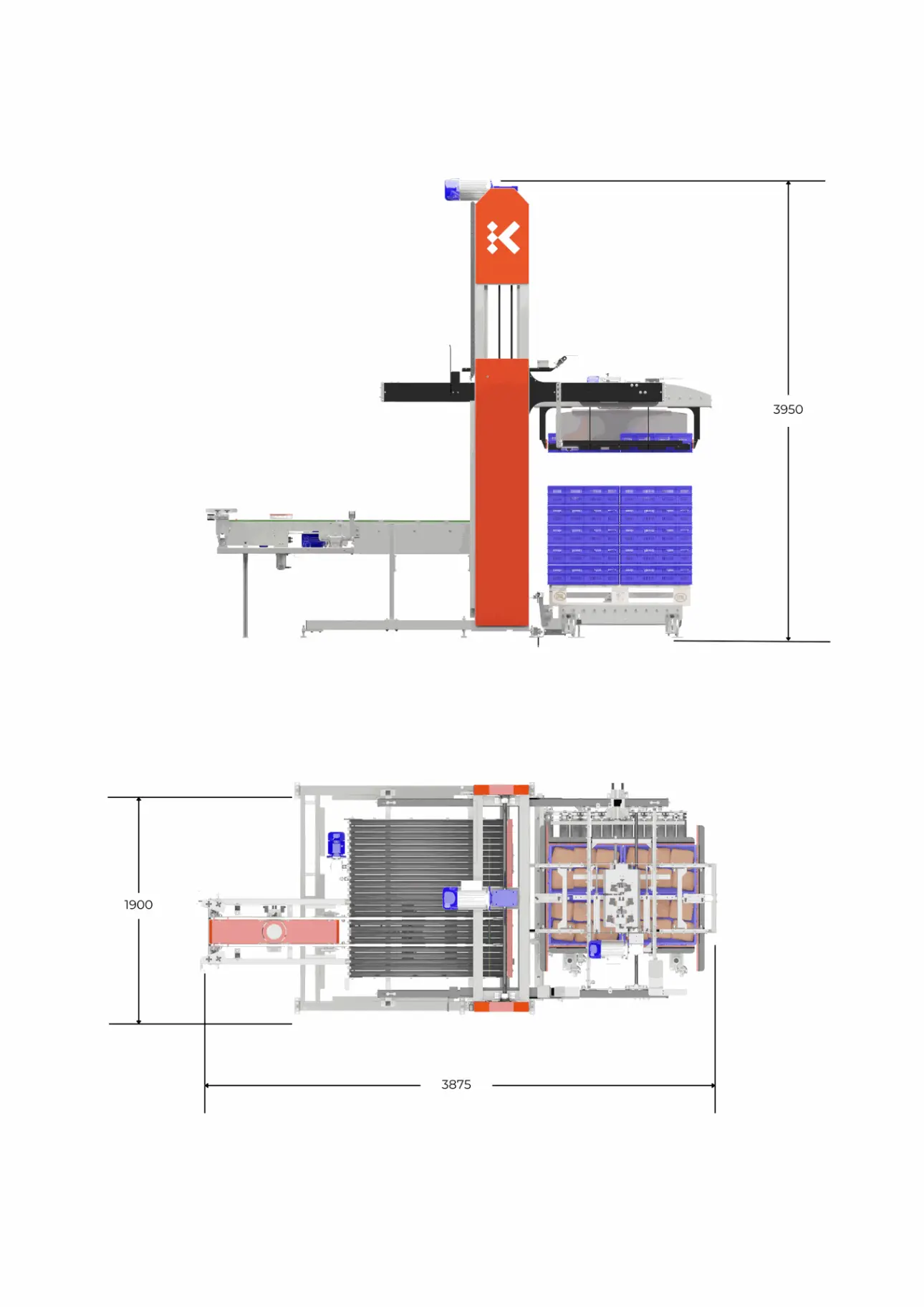

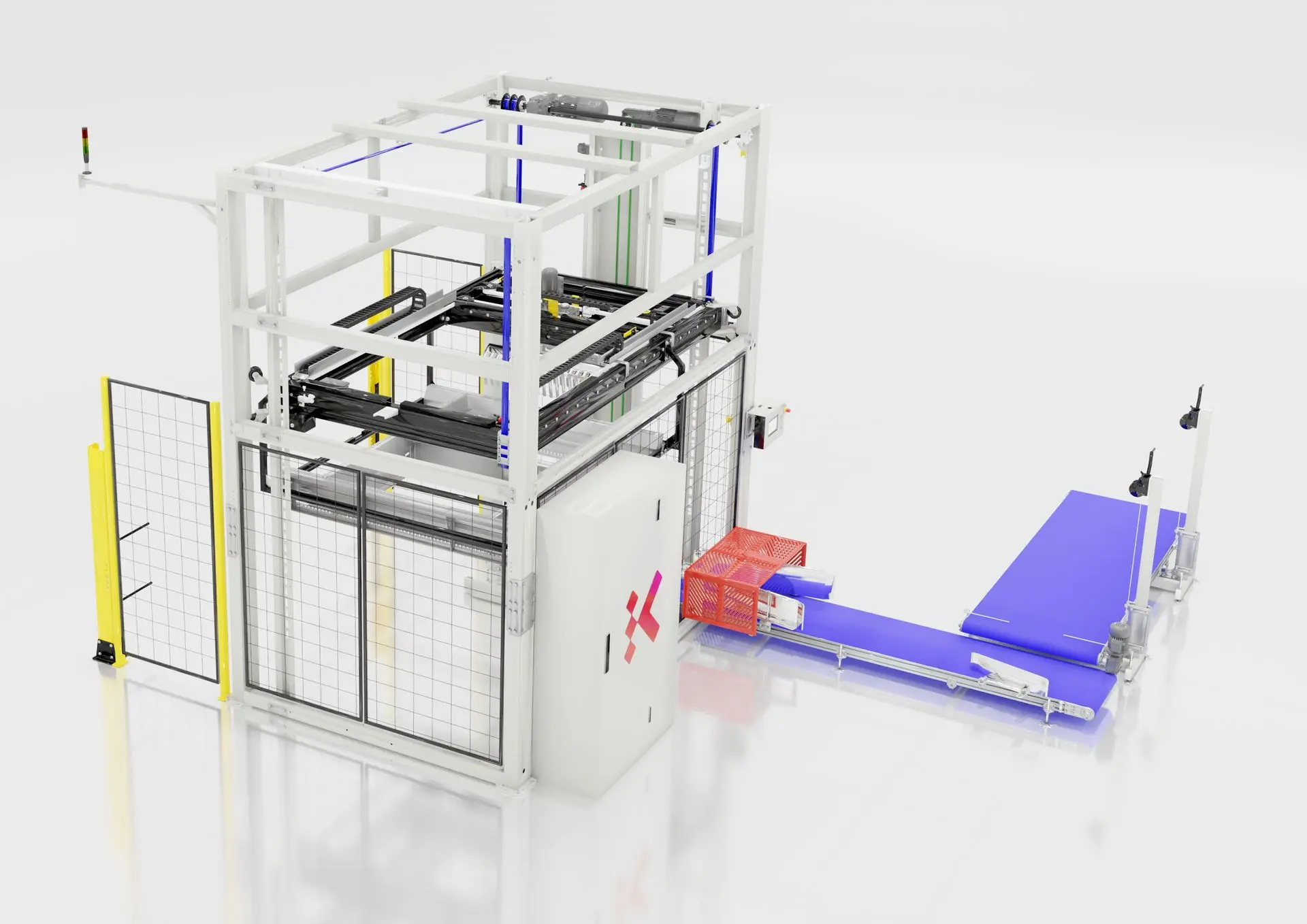

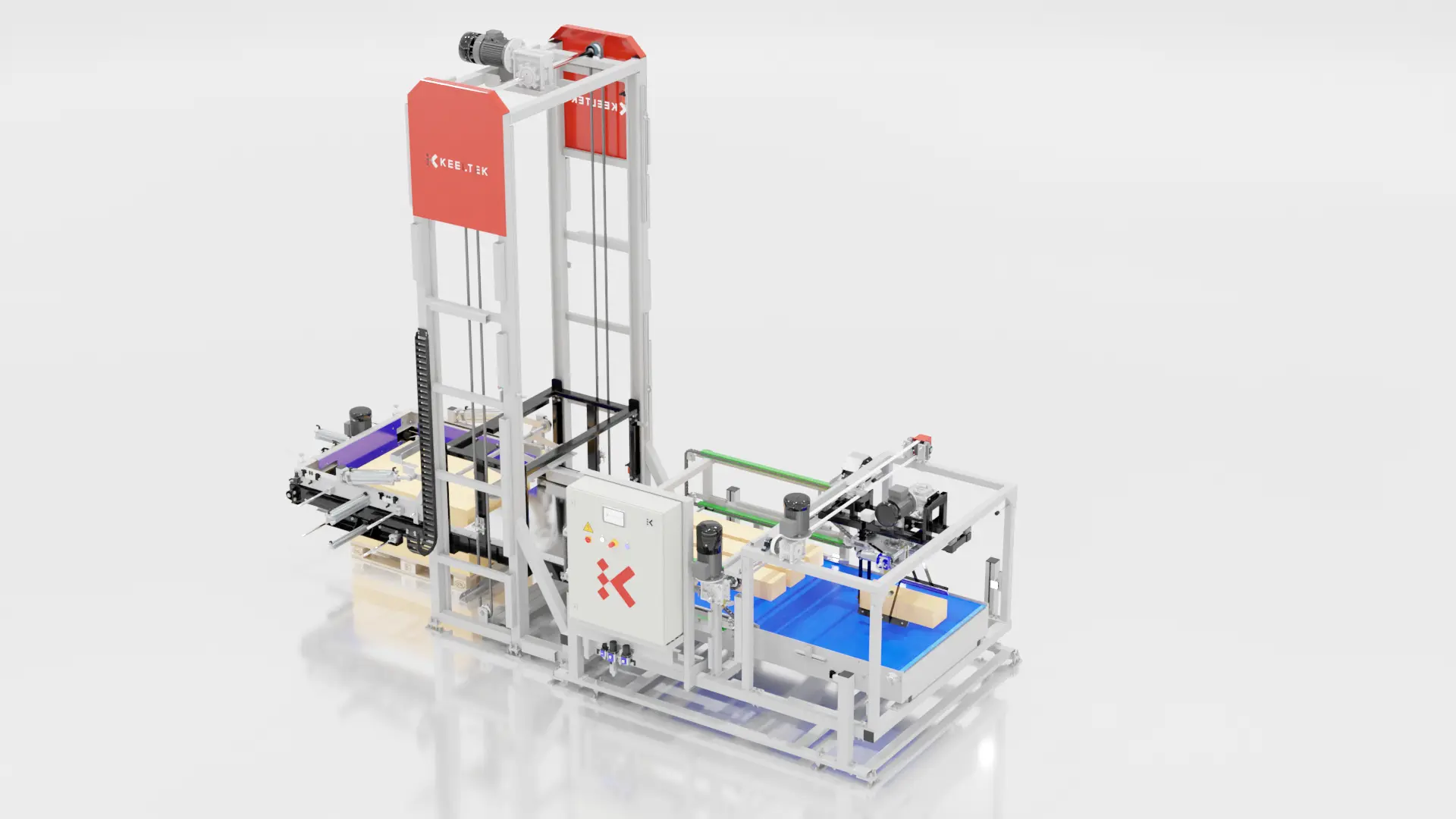

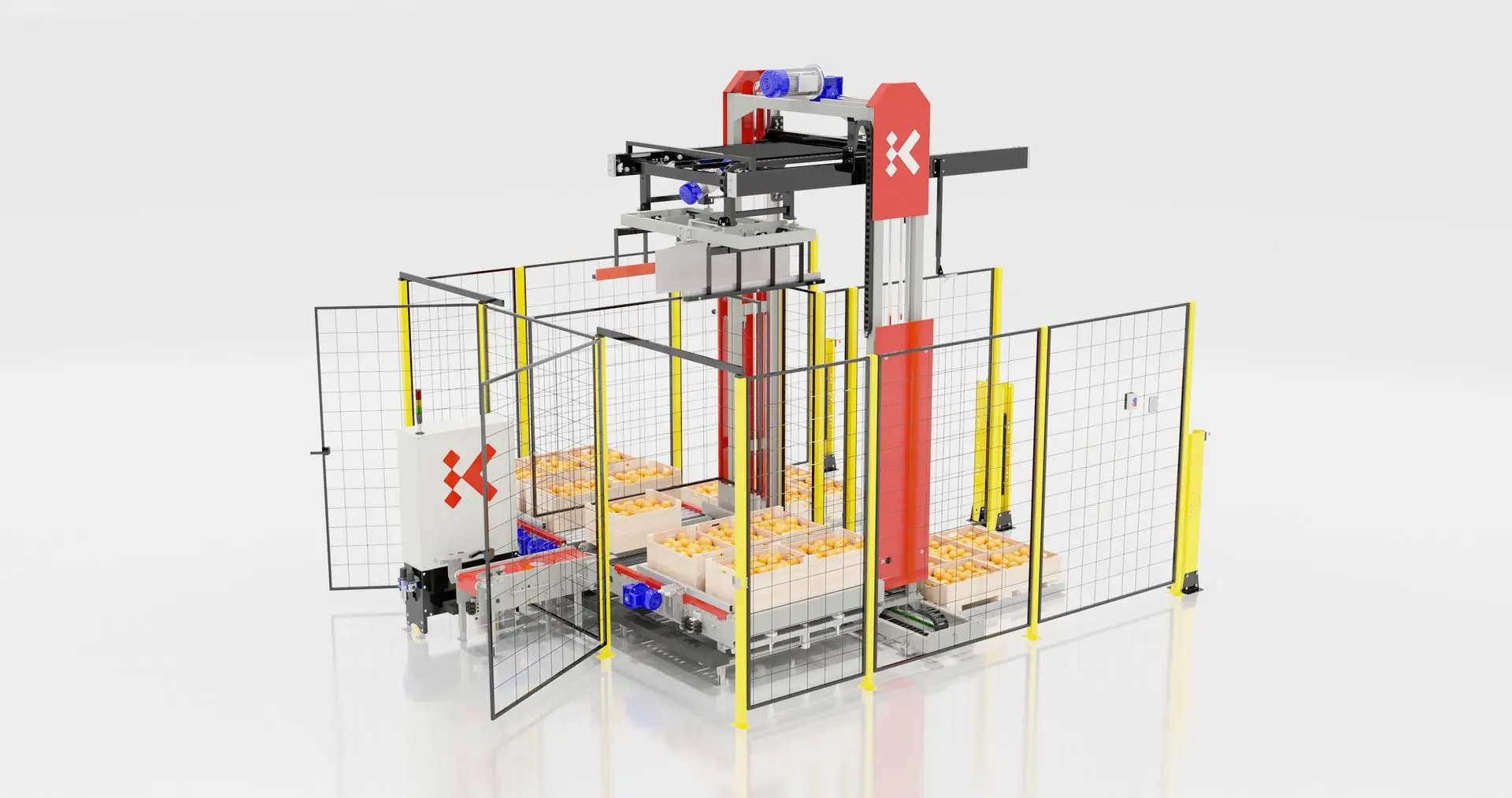

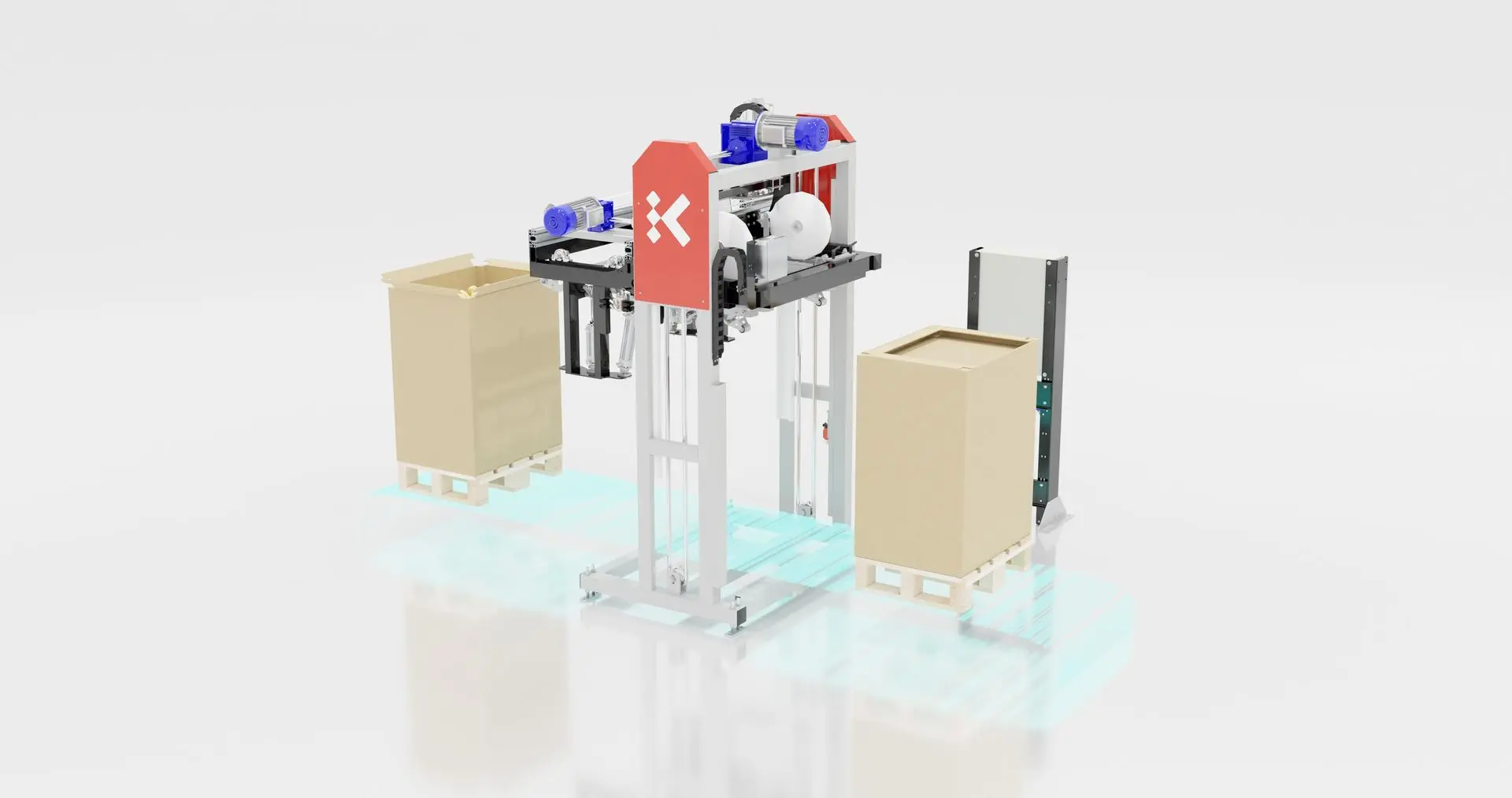

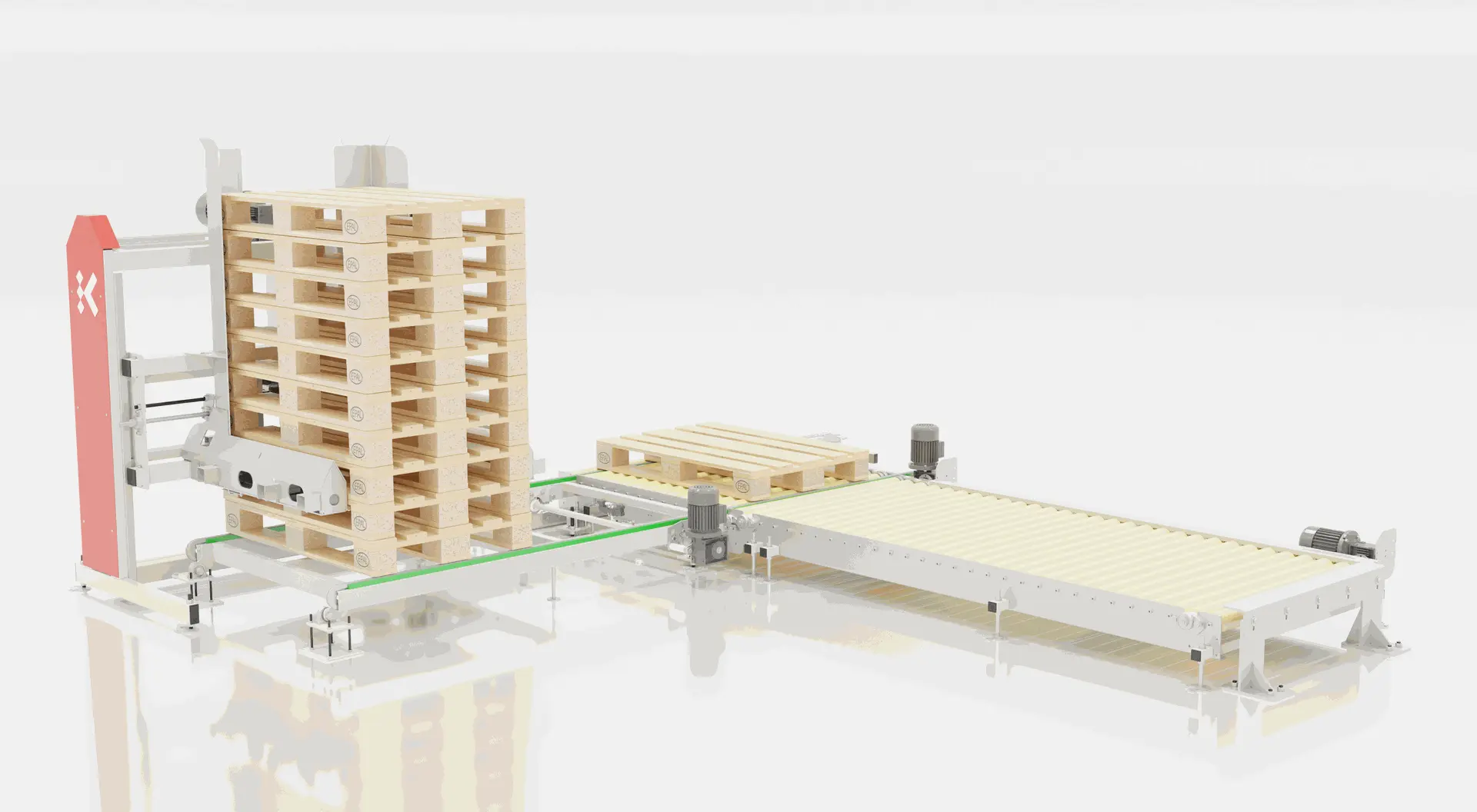

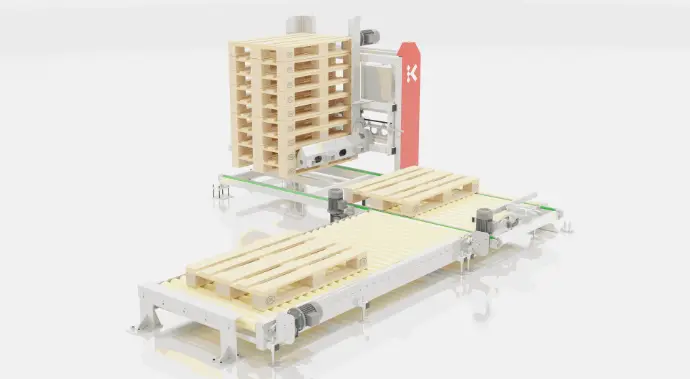

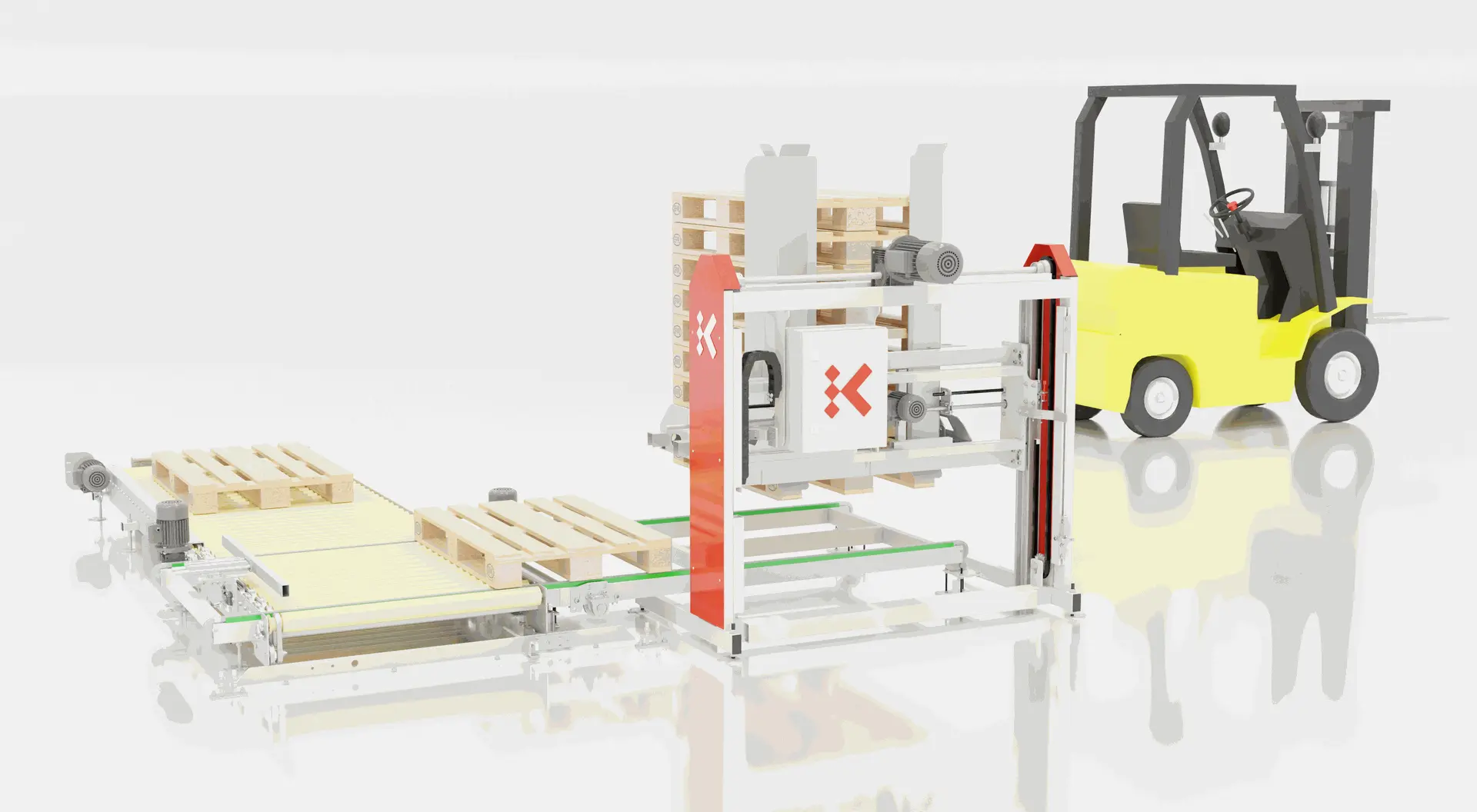

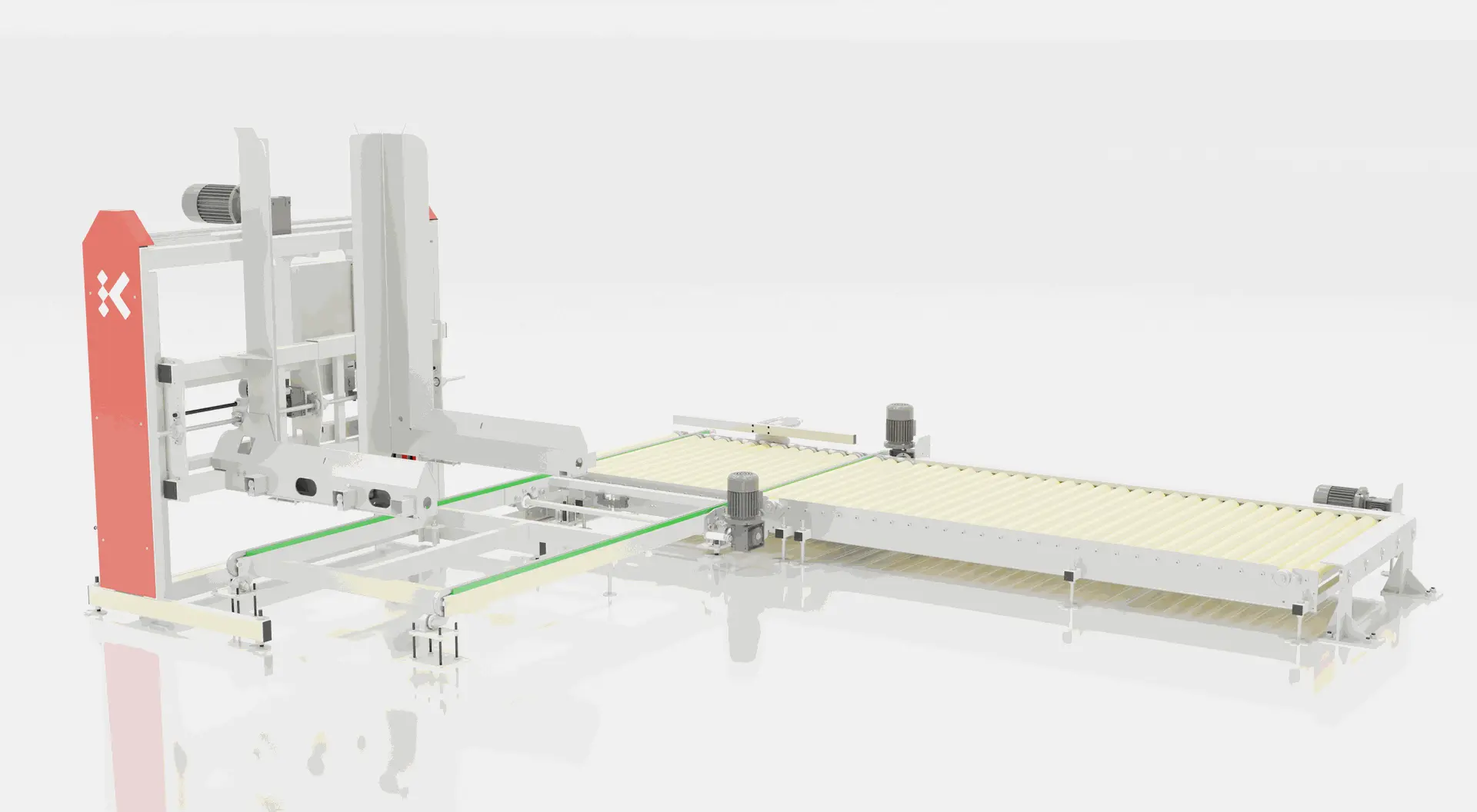

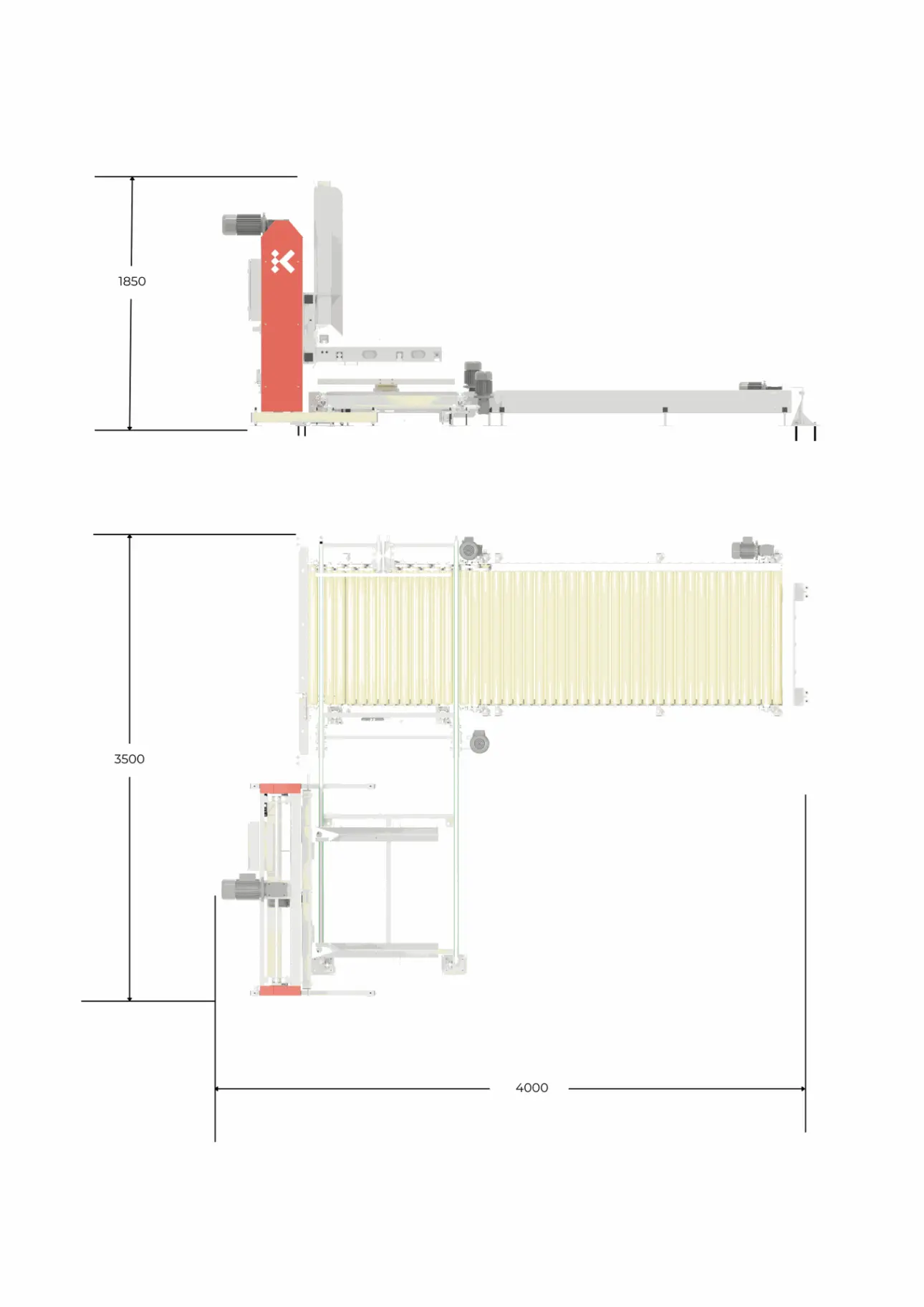

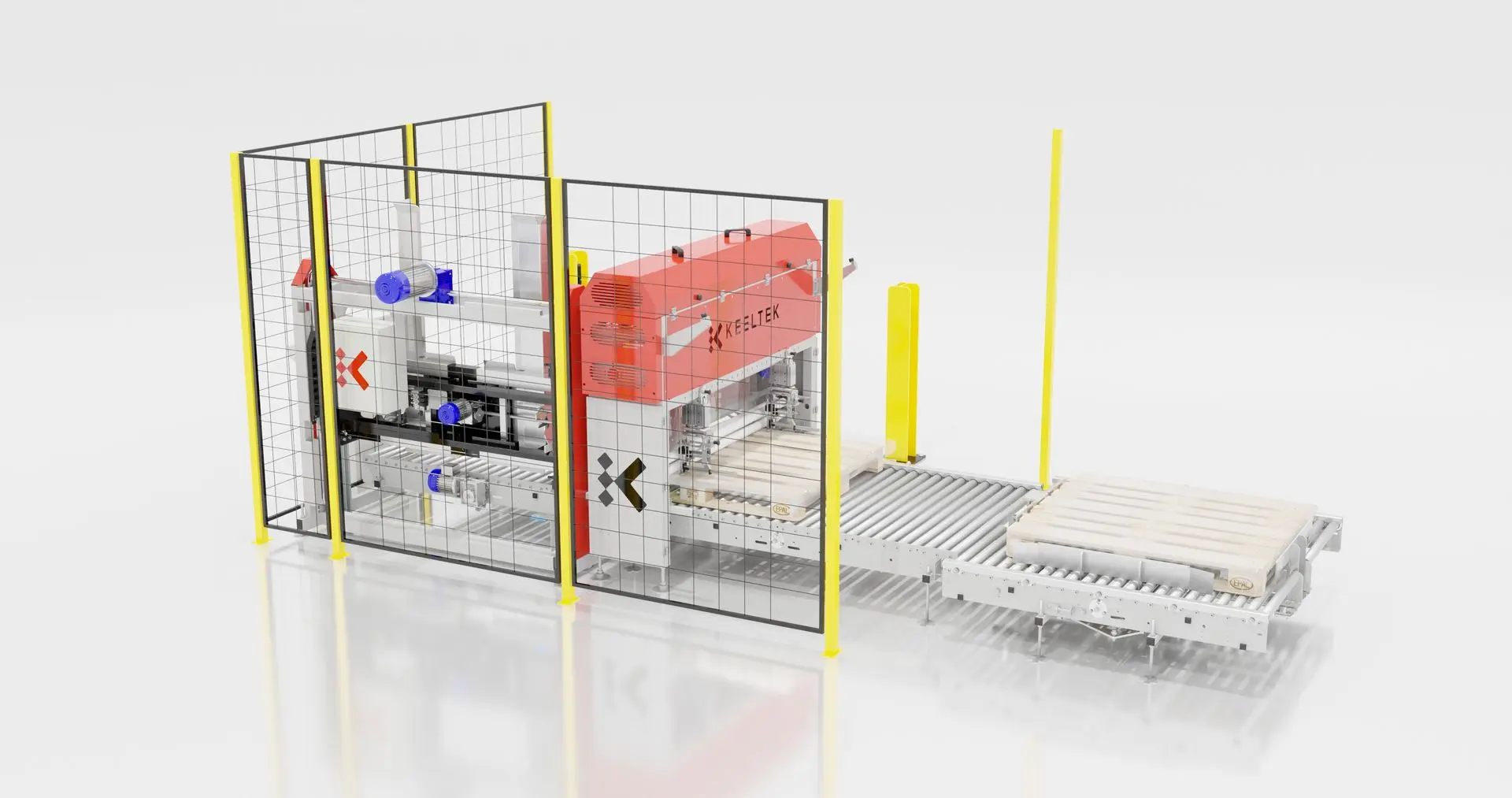

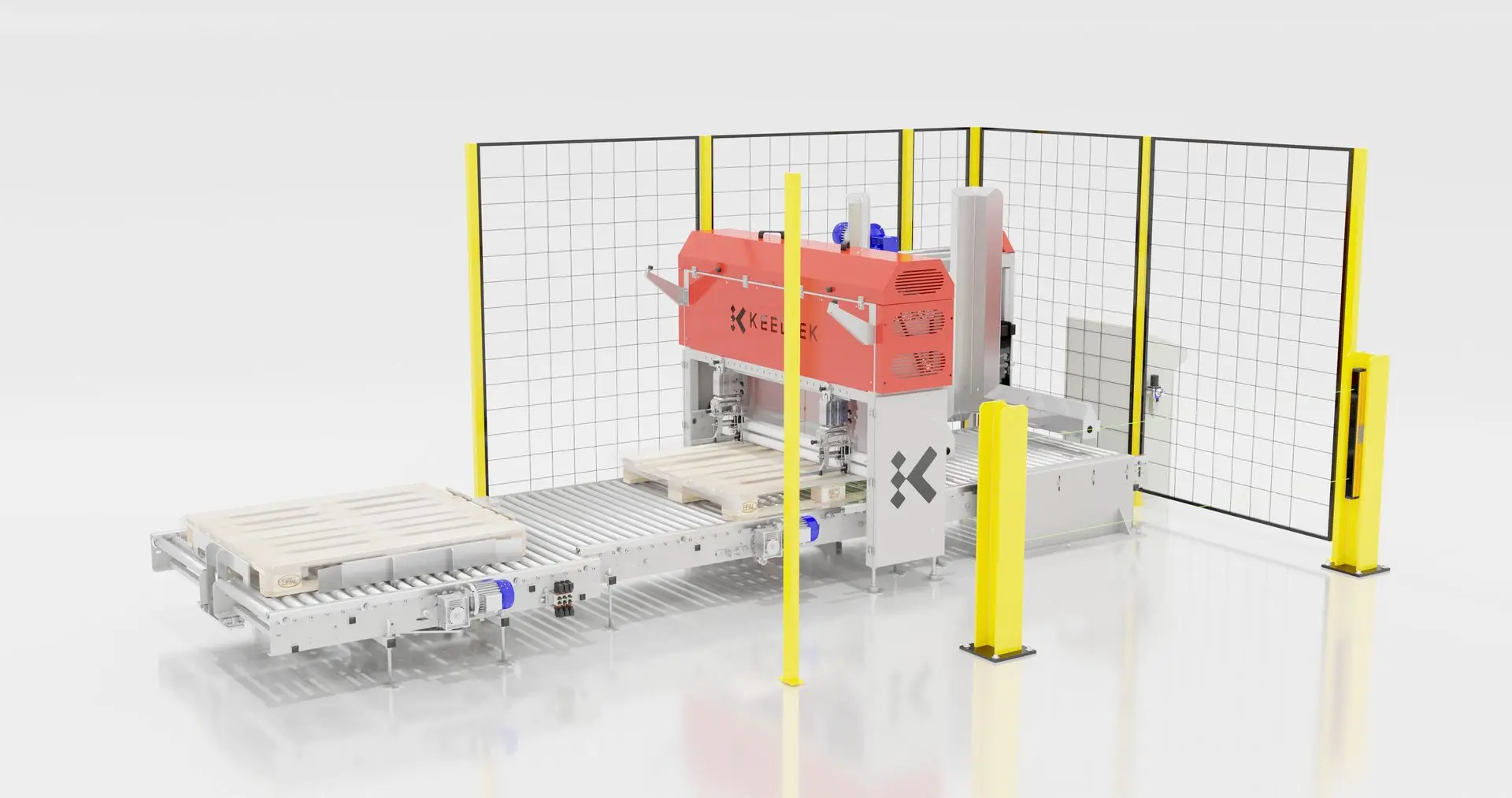

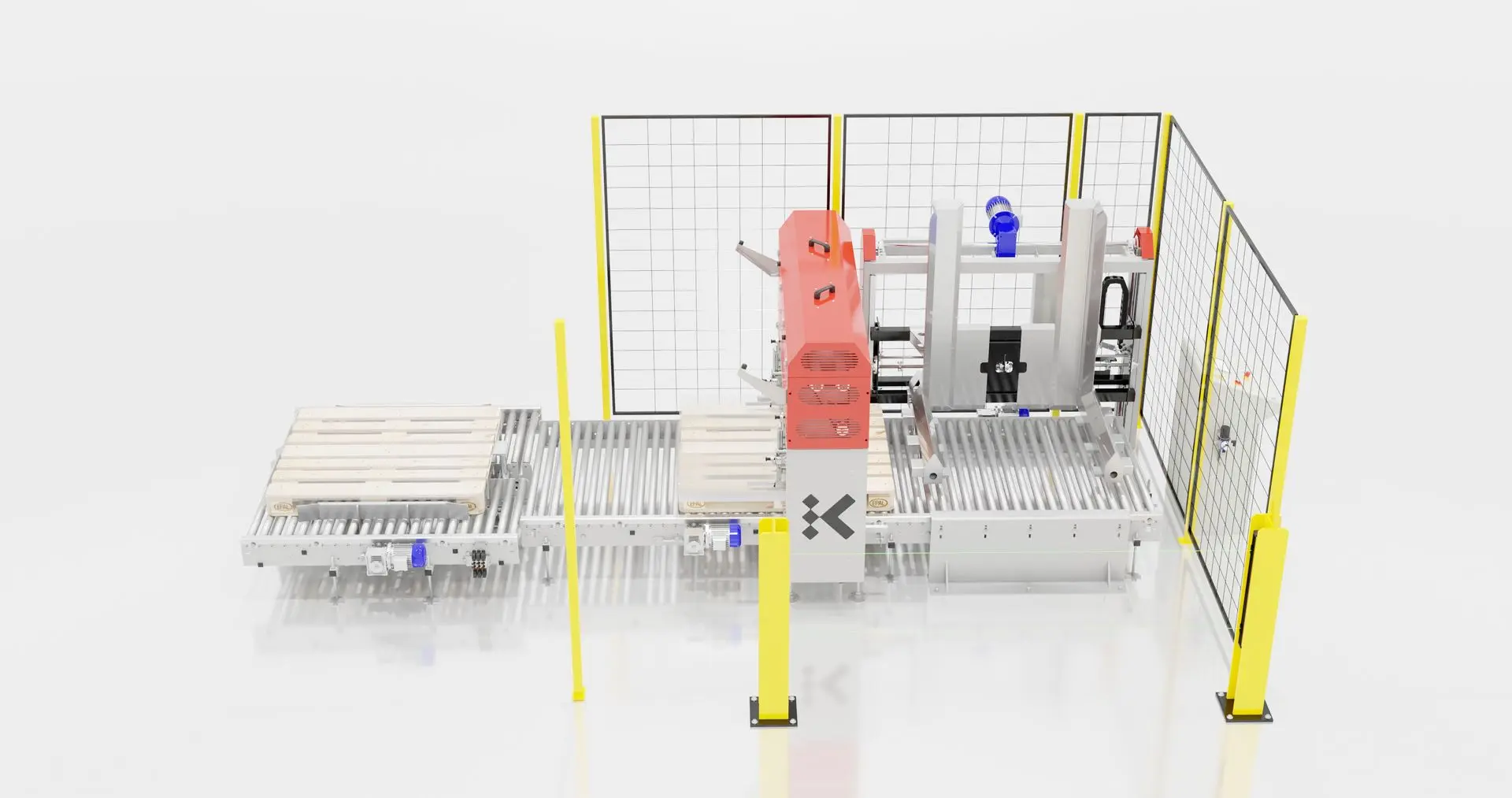

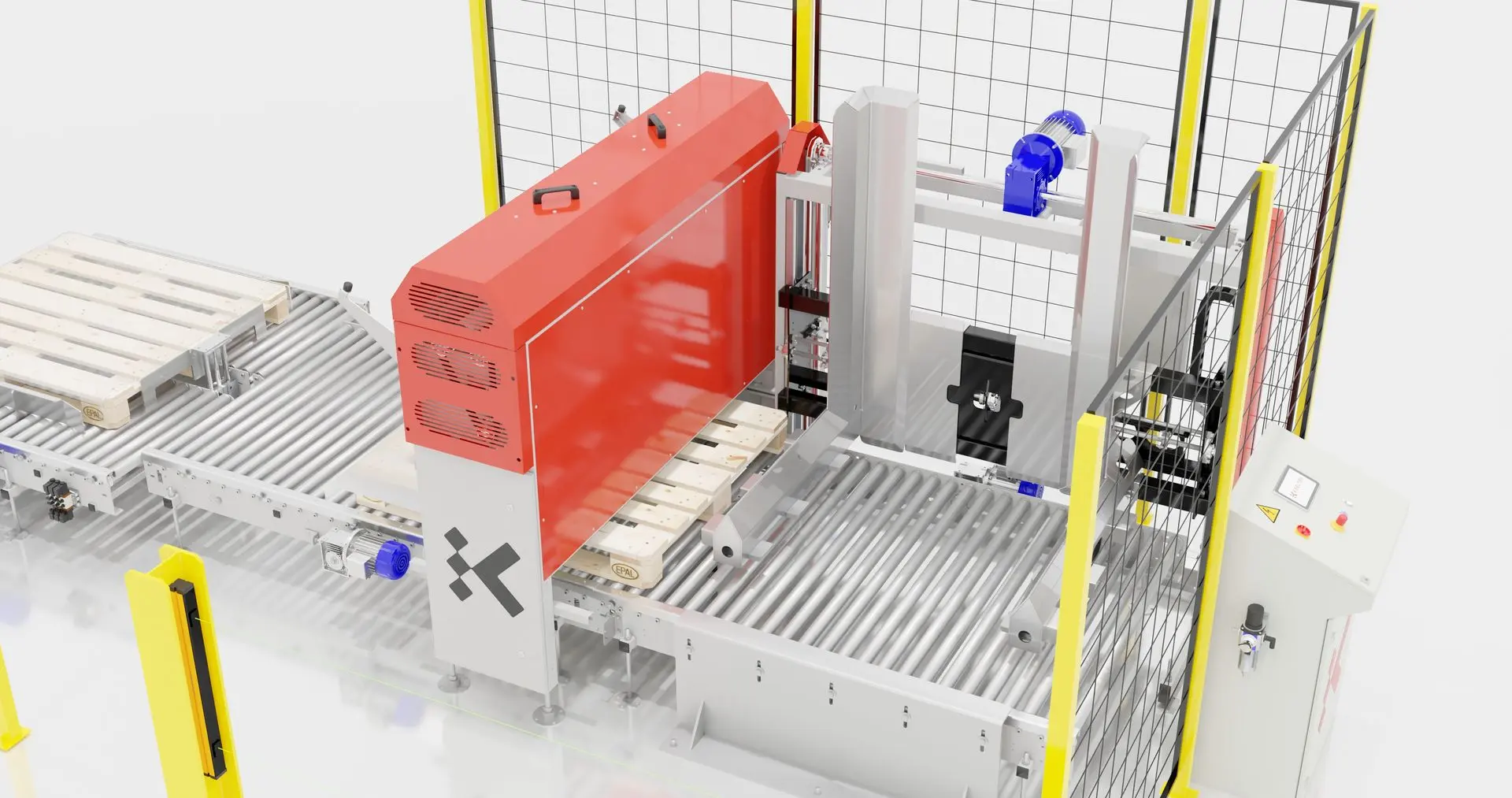

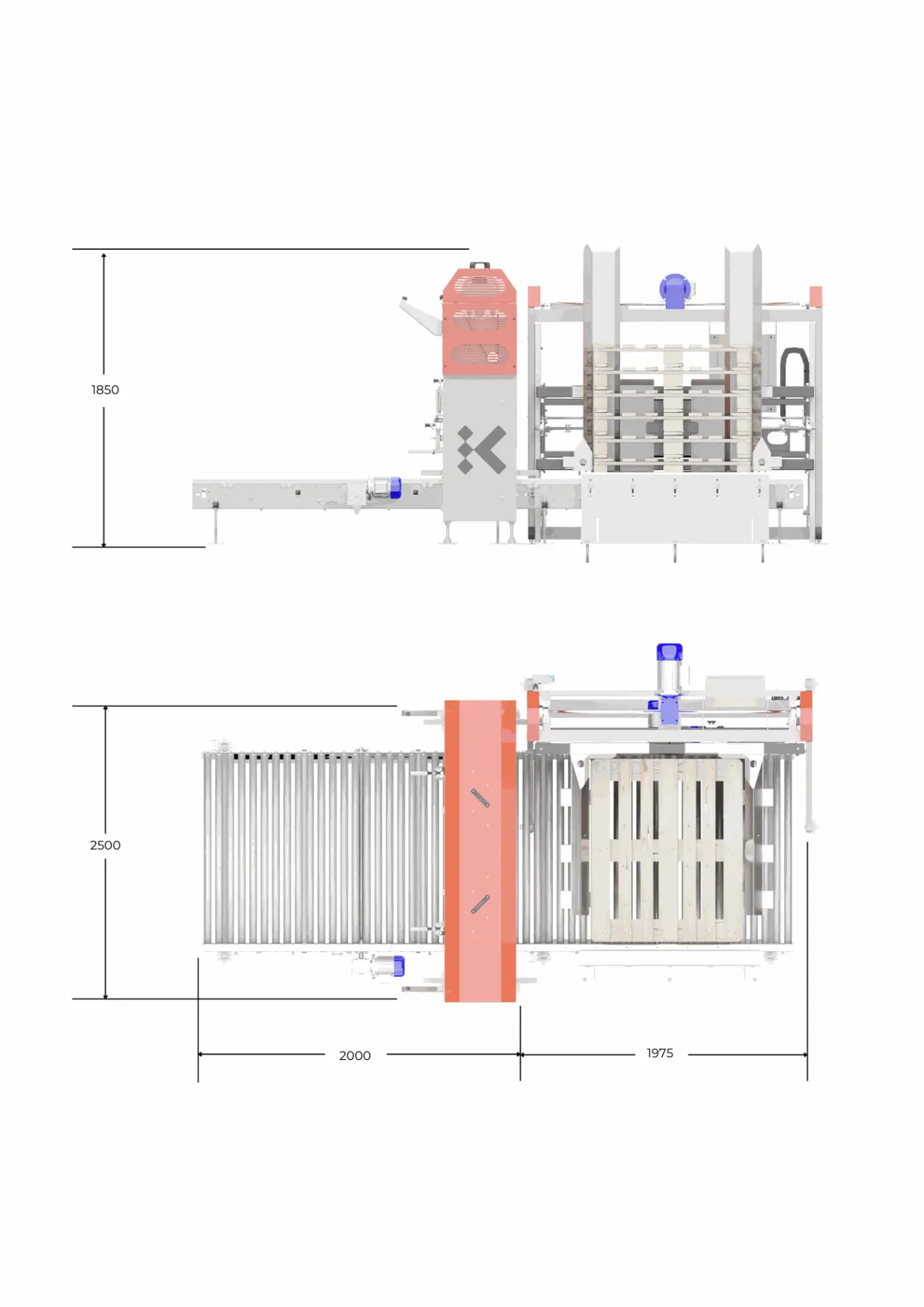

EASYPAL PLUS

2-axis Cartesian palletizer for boxes with pallet destacker

2-axis Cartesian palletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing boxes in layers. It incorporates an automatic pallet destacker to maximize production and avoid unnecessary stoppages to replace the pallet.

EASYPAL PLUS

2-axis Cartesian palletizer for boxes with pallet destacker

2-axis Cartesian palletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing boxes in layers. It incorporates an automatic pallet destacker to maximize production and avoid unnecessary stoppages to replace the pallet.

EASYPAL PLUS

2-axis Cartesian palletizer for boxes with pallet destacker

2-axis Cartesian palletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing boxes in layers. It incorporates an automatic pallet destacker to maximize production and avoid unnecessary stoppages to replace the pallet.

EASYPAL PLUS

2-axis Cartesian palletizer for boxes with pallet destacker

2-axis Cartesian palletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing boxes in layers. It incorporates an automatic pallet destacker to maximize production and avoid unnecessary stoppages to replace the pallet.

EASYPAL PLUS

2-axis Cartesian palletizer for boxes with pallet destacker

2-axis Cartesian palletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing boxes in layers. It incorporates an automatic pallet destacker to maximize production and avoid unnecessary stoppages to replace the pallet.

| Reference Product | Boxes of any size compatible with the pallet |

| Tiles | Any tile configuration. |

| Maximum permissible load | Up to 175 kg. |

|

Connectivity

|

Industry 4.0 Ready |

| Cadences | Up to 3 shots per minute. |

Equipment | Dispensador automático de pallets |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed using laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Rotator with selectable label positioning, high performance.

- Labeling machine integration.

- Reversed layer function for improved stability.

- Add pallet between layers function. (Manual or automatic).

- KTS, remote assistance.

- Full stainless steel finishes

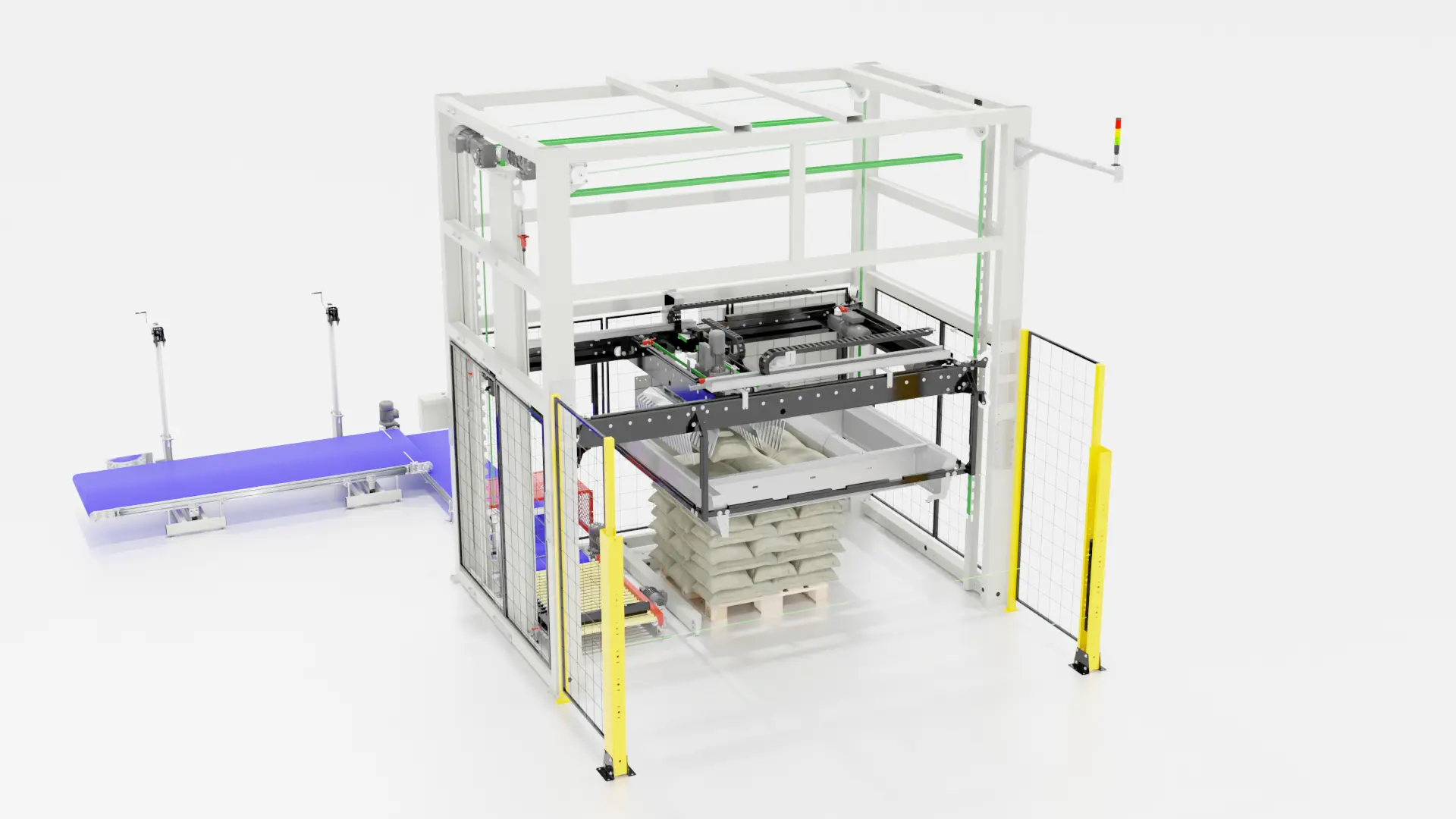

BAGPAL

4-axis Cartesian palletizer for bags

4-axis Cartesian palletizer with gripper and rotation system, primarily designed for palletizing bags, but capable of handling other products.

BAGPAL

4-axis Cartesian palletizer for bags

4-axis Cartesian palletizer with gripper and rotation system, primarily designed for palletizing bags, but capable of handling other products.

BAGPAL

4-axis Cartesian palletizer for bags

4-axis Cartesian palletizer with gripper and rotation system, primarily designed for palletizing bags, but capable of handling other products.

BAGPAL

4-axis Cartesian palletizer for bags

4-axis Cartesian palletizer with gripper and rotation system, primarily designed for palletizing bags, but capable of handling other products.

BAGPAL

4-axis Cartesian palletizer for bags

4-axis Cartesian palletizer with gripper and rotation system, primarily designed for palletizing bags, but capable of handling other products.

BAGPAL

4-axis Cartesian palletizer for bags

4-axis Cartesian palletizer with gripper and rotation system, primarily designed for palletizing bags, but capable of handling other products.

BAGPAL

4-axis Cartesian palletizer for bags

4-axis Cartesian palletizer with gripper and rotation system, primarily designed for palletizing bags, but capable of handling other products.

| Reference Product | Bags from 5 to 50 kg. For other formats, please inquire. |

| Tiles | Any tile configuration. |

| Maximum permissible load | Up to 50 kg |

|

Connectivity

|

Industry 4.0 Ready |

| Cadences | Up to 10 cycles per minute |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed using laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Automatic pallet dispenser and changer.

- Multi-clamp for boxes and bags.

- KTS, remote assistance.

- Full stainless steel finishes

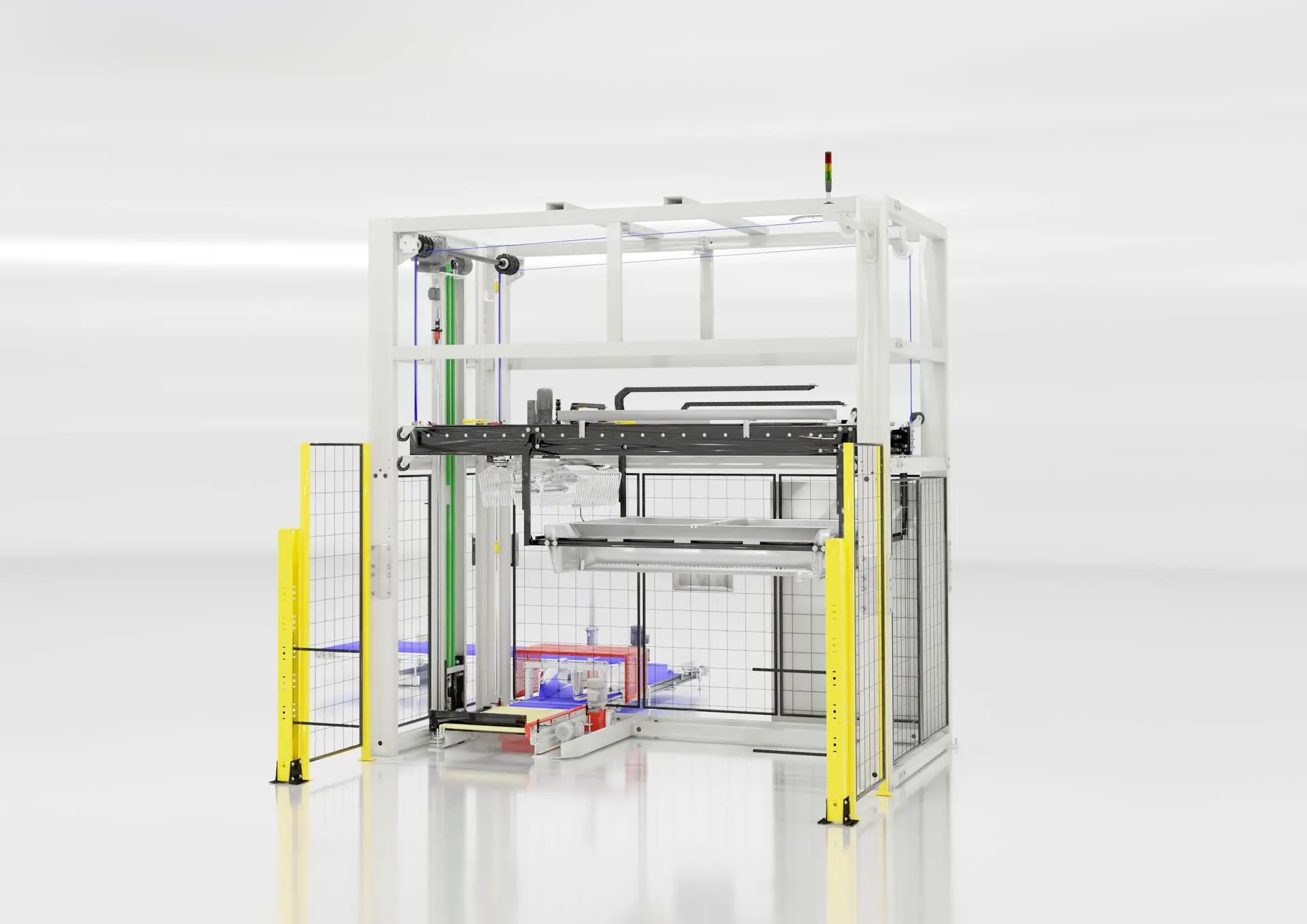

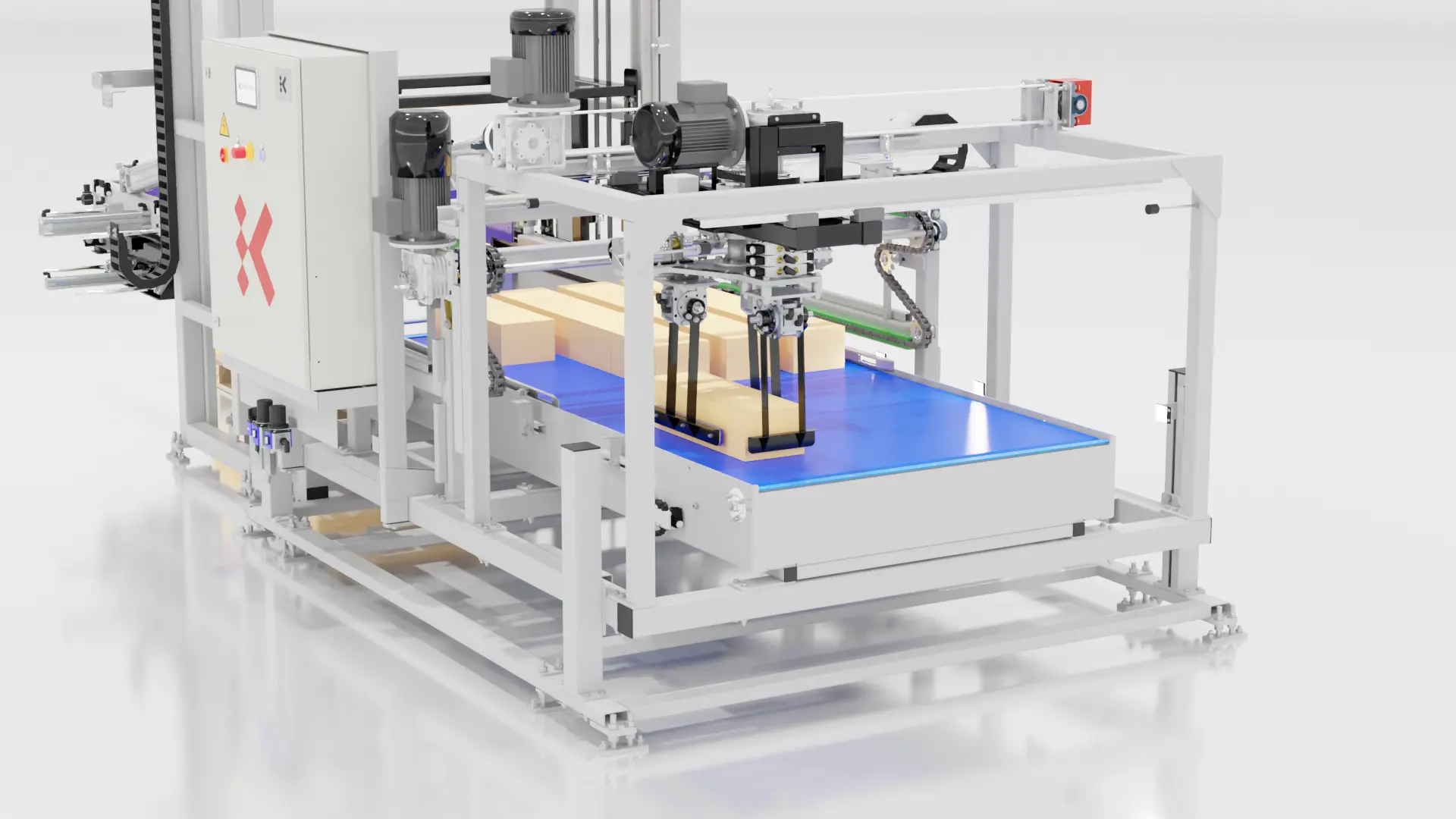

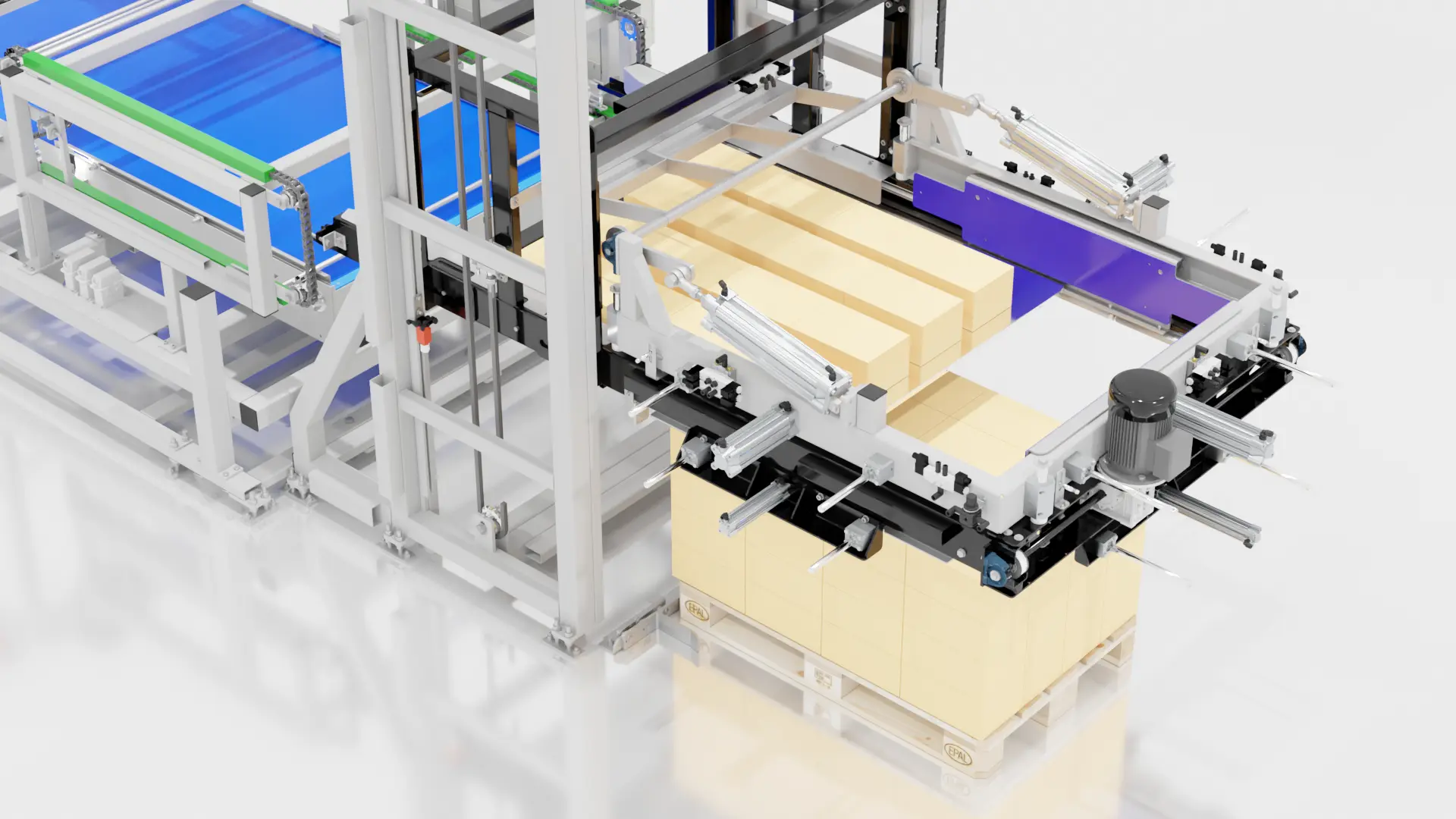

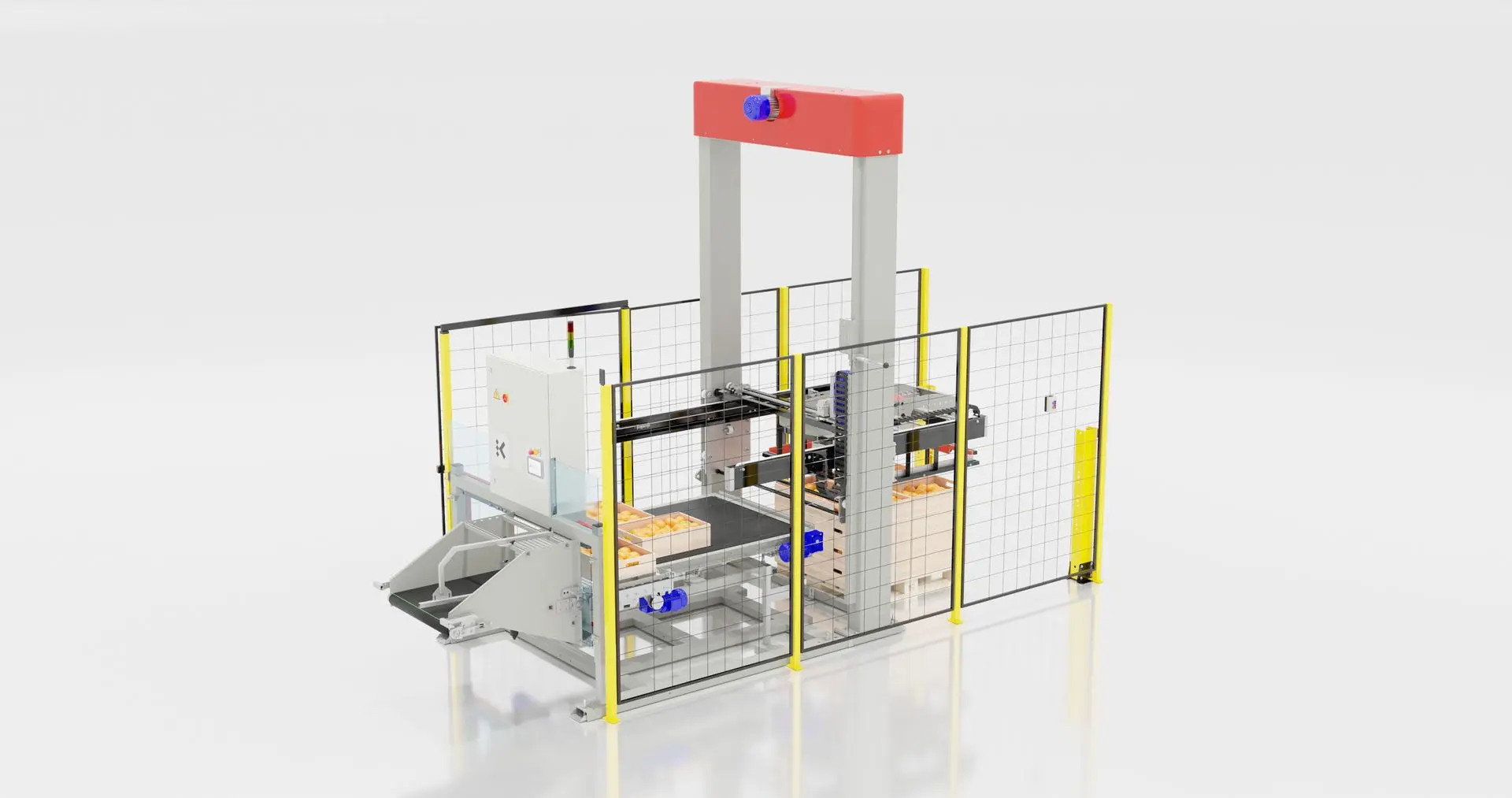

PLATEPAL

Cartesian layer palletizer with horizontal plate

2-axis Cartesian palletizer with horizontal plate, with box positioning and rotation system, designed for palletizing layers of boxes containing products that cannot withstand much lateral pressure.

PLATEPAL

Cartesian layer palletizer with horizontal plate

2-axis Cartesian palletizer with horizontal plate, with box positioning and rotation system, designed for palletizing layers of boxes containing products that cannot withstand much lateral pressure.

PLATEPAL

Cartesian layer palletizer with horizontal plate

2-axis Cartesian palletizer with horizontal plate, with box positioning and rotation system, designed for palletizing layers of boxes containing products that cannot withstand much lateral pressure.

PLATEPAL

Cartesian layer palletizer with horizontal plate

2-axis Cartesian palletizer with horizontal plate, with box positioning and rotation system, designed for palletizing layers of boxes containing products that cannot withstand much lateral pressure.

PLATEPAL

Cartesian layer palletizer with horizontal plate

2-axis Cartesian palletizer with horizontal plate, with box positioning and rotation system, designed for palletizing layers of boxes containing products that cannot withstand much lateral pressure.

| Reference Product | Boxes of any size compatible with the pallet |

| Tiles | Any tile configuration. |

| Maximum permissible load | Up to 175 kg |

|

Connectivity

|

Industry 4.0 Ready |

| Cadences | Up to 3 shots per minute |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed using laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Rotator with selectable label positioning, high performance.

- Labeling machine integration.

- Automatic pallet dispenser and changer.

- Add pallet between layers function. (Manual or automatic)

- KTS, remote assistance.

- Full stainless steel finishes

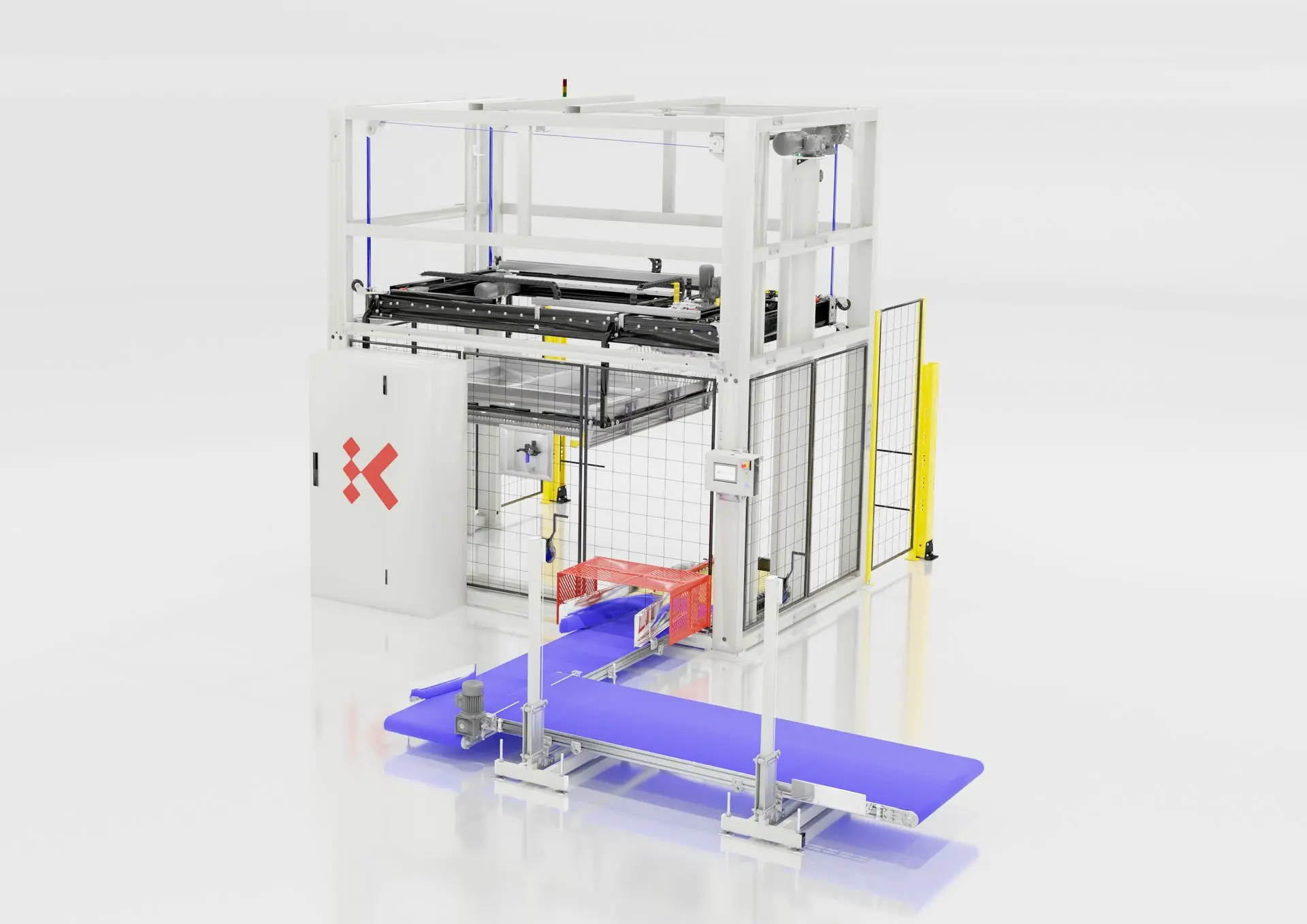

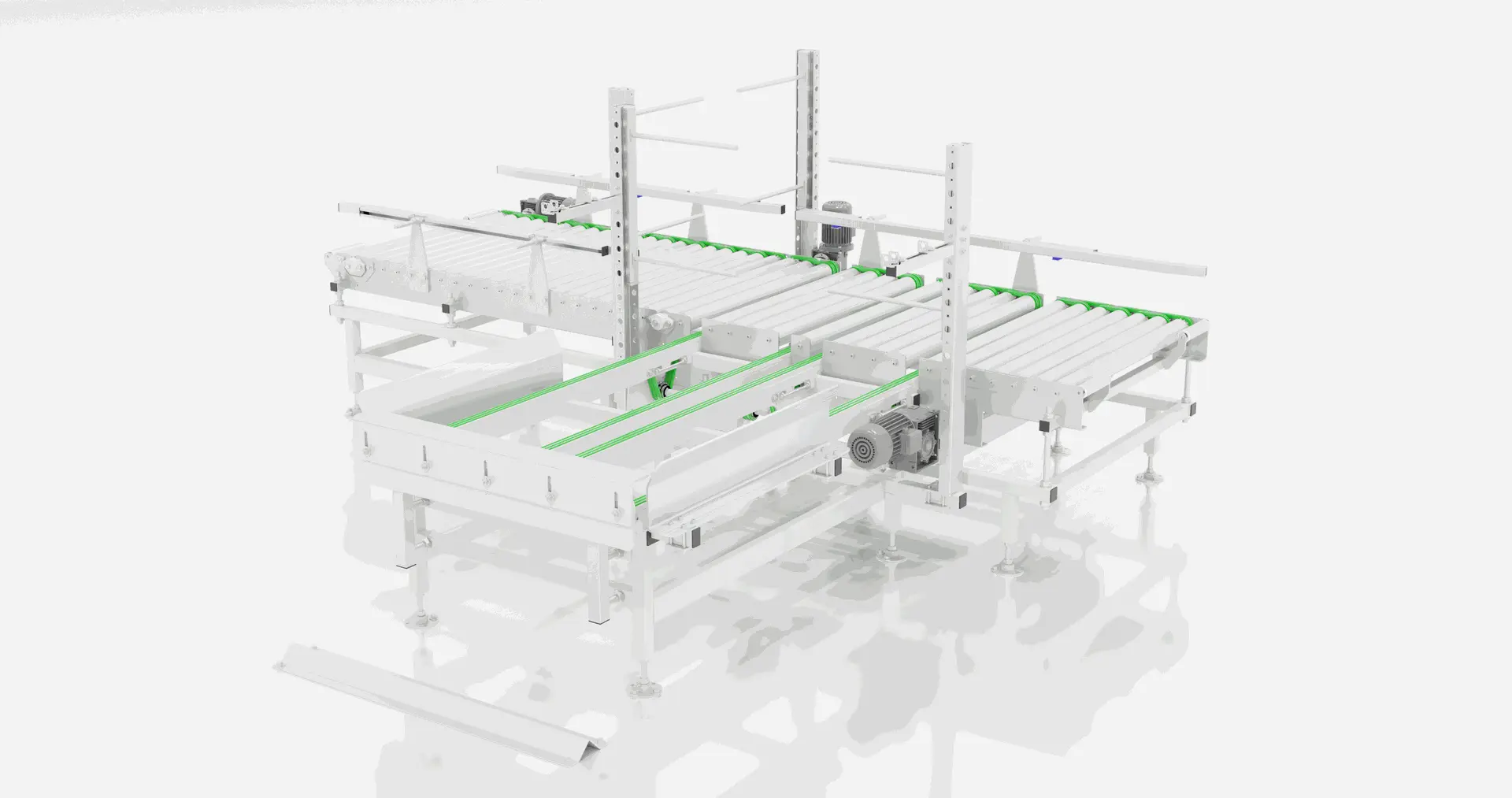

UNIPAL

Two-axis Cartesian palletizer by layers for any type of box

2-axis Cartesian palletizer with combined canvas and roller table, with box gripping system using a clamp equipped with 4 jaws, designed for palletizing layers of any type of box.

UNIPAL

Two-axis Cartesian palletizer by layers for any type of box

2-axis Cartesian palletizer with combined canvas and roller table, with box gripping system using a clamp equipped with 4 jaws, designed for palletizing layers of any type of box.

UNIPAL

Two-axis Cartesian palletizer by layers for any type of box

2-axis Cartesian palletizer with combined canvas and roller table, with box gripping system using a clamp equipped with 4 jaws, designed for palletizing layers of any type of box.

UNIPAL

Two-axis Cartesian palletizer by layers for any type of box

2-axis Cartesian palletizer with combined canvas and roller table, with box gripping system using a clamp equipped with 4 jaws, designed for palletizing layers of any type of box.

UNIPAL

Two-axis Cartesian palletizer by layers for any type of box

2-axis Cartesian palletizer with combined canvas and roller table, with box gripping system using a clamp equipped with 4 jaws, designed for palletizing layers of any type of box.

Perfecto para los siguientes sectores:

Food and beverage

| Reference Product | Boxes of any size compatible with the pallet |

| Tiles | Any tile configuration. |

| Maximum permissible load | Up to 175 kg. |

|

Connectivity

|

Industry 4.0 Ready |

| Cadences | Up to 3 shots per minute. |

Equipment | Rotator with selectable label positioning. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed using laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Rotator with selectable label positioning.

- Labeling machine integration.

- Automatic pallet dispenser and changer.

- Reversed layer function for improved stability.

- Add pallet between layers function. (Manual or automatic)

- KTS, remote assistance.

- Full stainless steel finishes

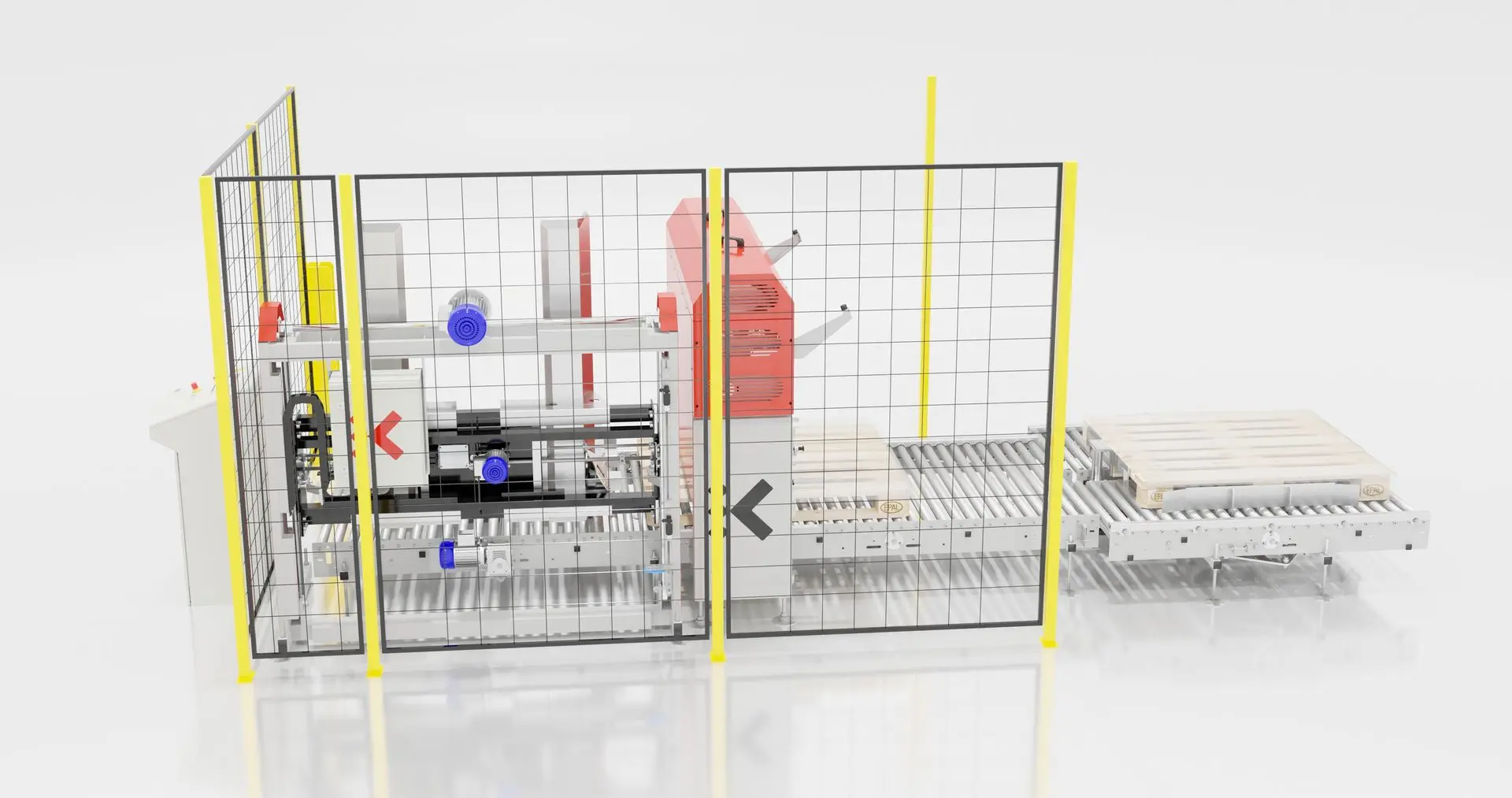

TRACKPAL

Cartesian layer palletizer on track

Two-axis Cartesian palletizer mounted on a track, enabling work in two different palletizing positions to maximize performance. The product is automatically diverted to the active palletizing area, achieving 100% continuous production.

TRACKPAL

Cartesian layer palletizer on track

Two-axis Cartesian palletizer mounted on a track, enabling work in two different palletizing positions to maximize performance. The product is automatically diverted to the active palletizing area, achieving 100% continuous production.

TRACKPAL

Cartesian layer palletizer on track

Two-axis Cartesian palletizer mounted on a track, enabling work in two different palletizing positions to maximize performance. The product is automatically diverted to the active palletizing area, achieving 100% continuous production.

TRACKPAL

Cartesian layer palletizer on track

Two-axis Cartesian palletizer mounted on a track, enabling work in two different palletizing positions to maximize performance. The product is automatically diverted to the active palletizing area, achieving 100% continuous production.

TRACKPAL

Cartesian layer palletizer on track

Two-axis Cartesian palletizer mounted on a track, enabling work in two different palletizing positions to maximize performance. The product is automatically diverted to the active palletizing area, achieving 100% continuous production.

| Reference Product | Boxes of any size compatible with the pallet |

| Tiles | Any tile configuration. |

| Maximum permissible load | Up to 175 kg. |

|

Connectivity

|

Industry 4.0 Ready |

| Cadences | Up to 3 shots per minute. |

Equipment | Rotator with selectable label positioning. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed using laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Labeling machine integration.

- Automatic pallet dispenser and changer.

- Reversed layer function for improved stability.

- Add pallet between layers function. (Manual or automatic).

- KTS, remote assistance.

- Full stainless steel finishes

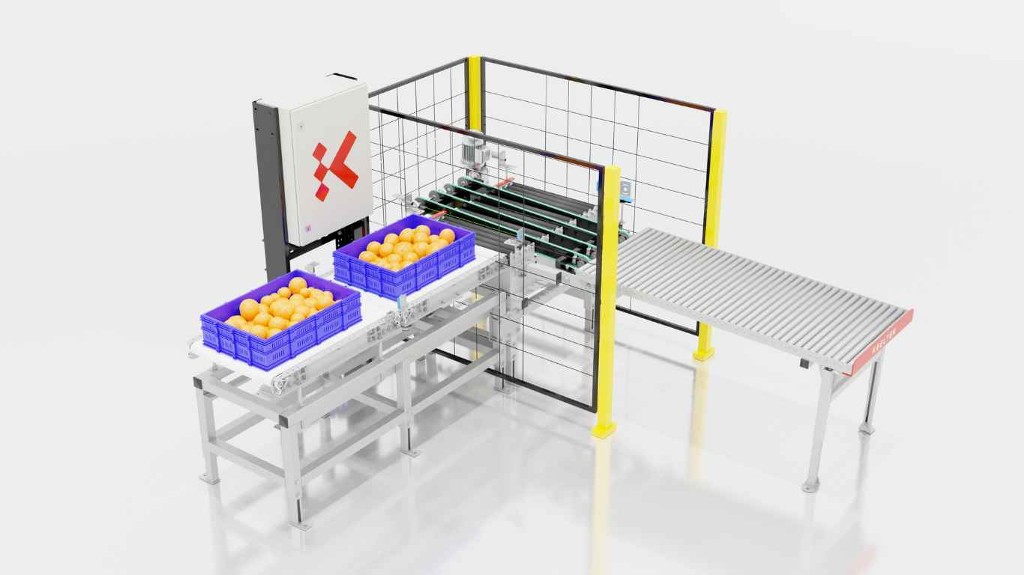

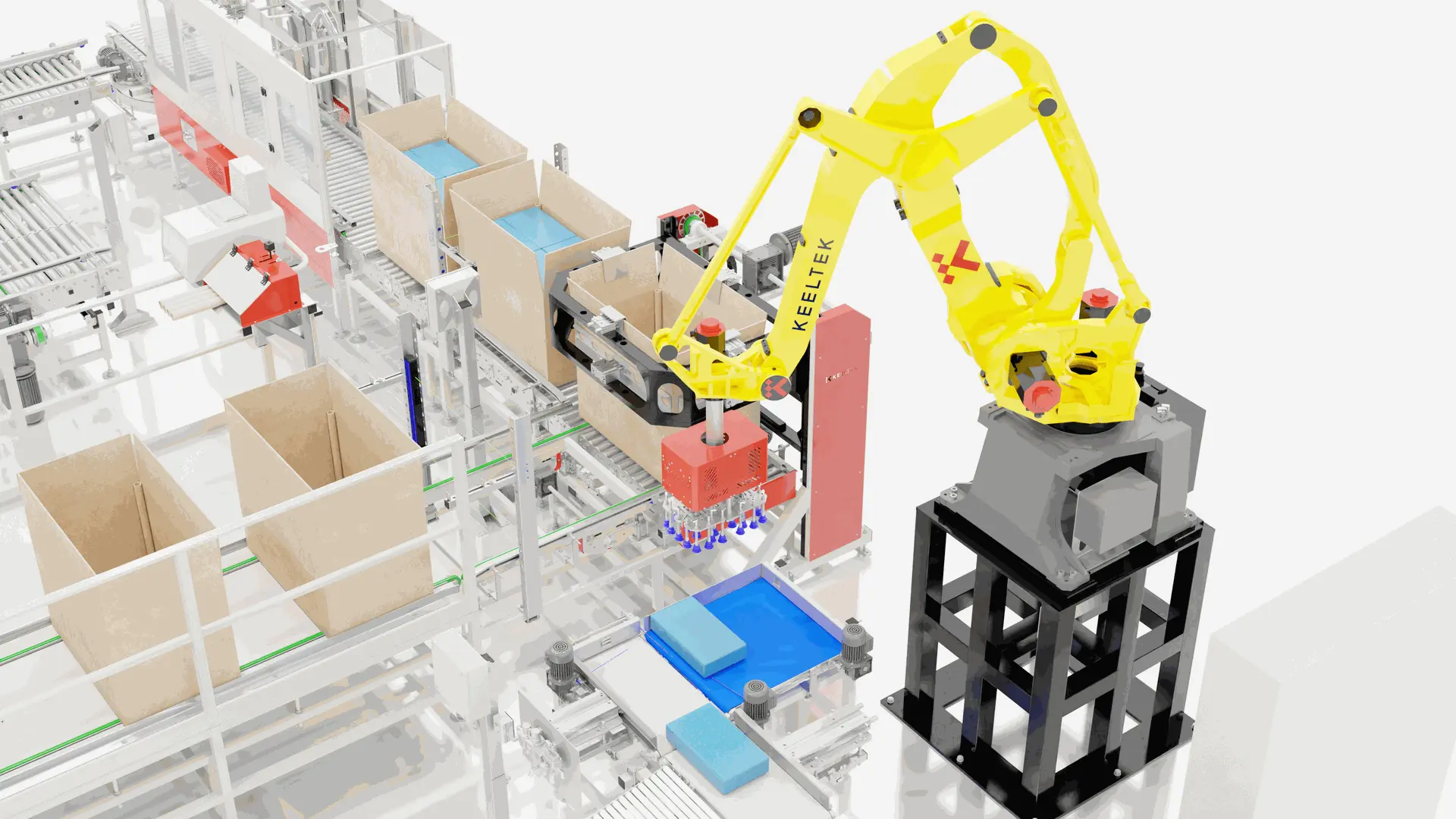

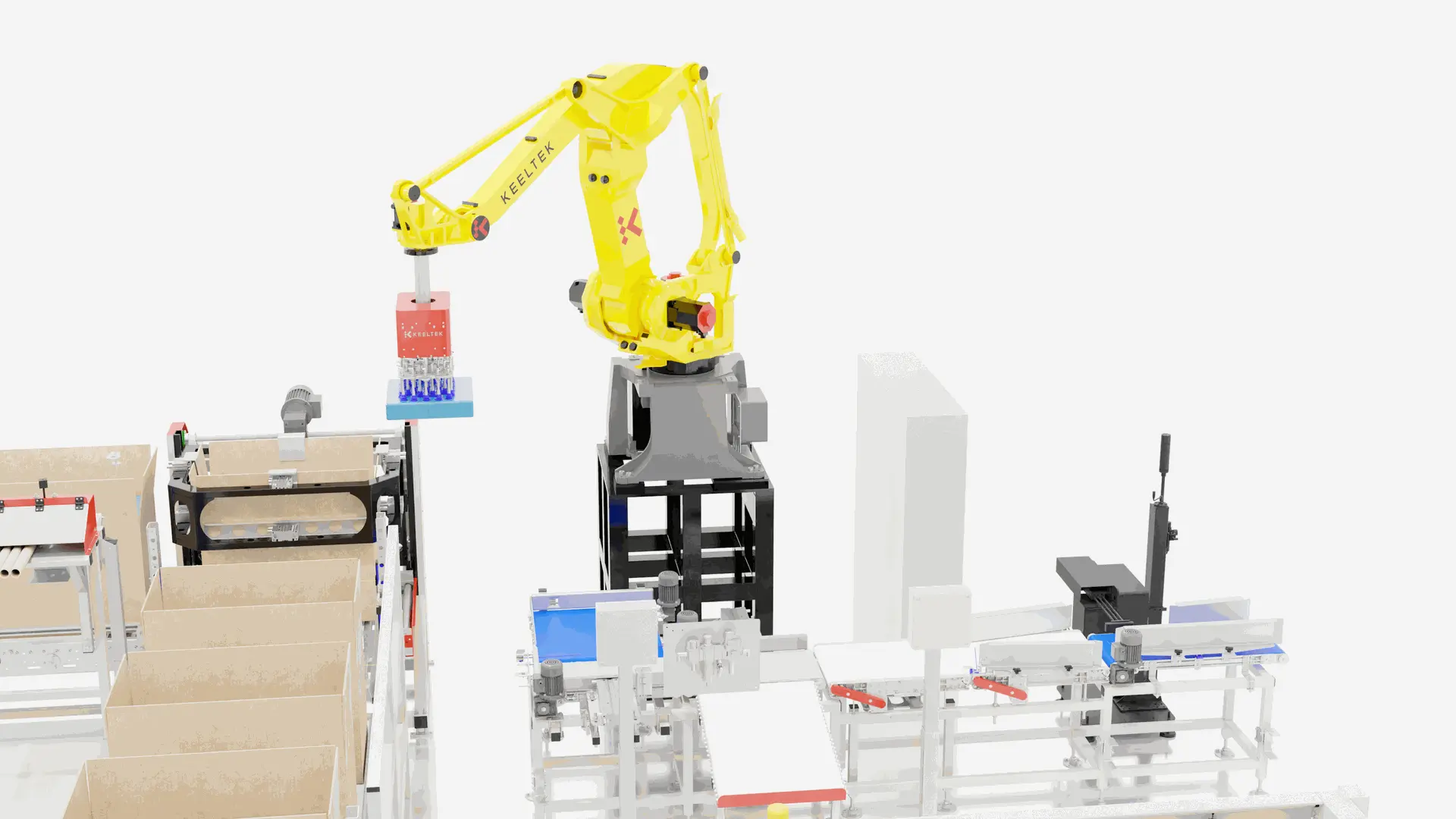

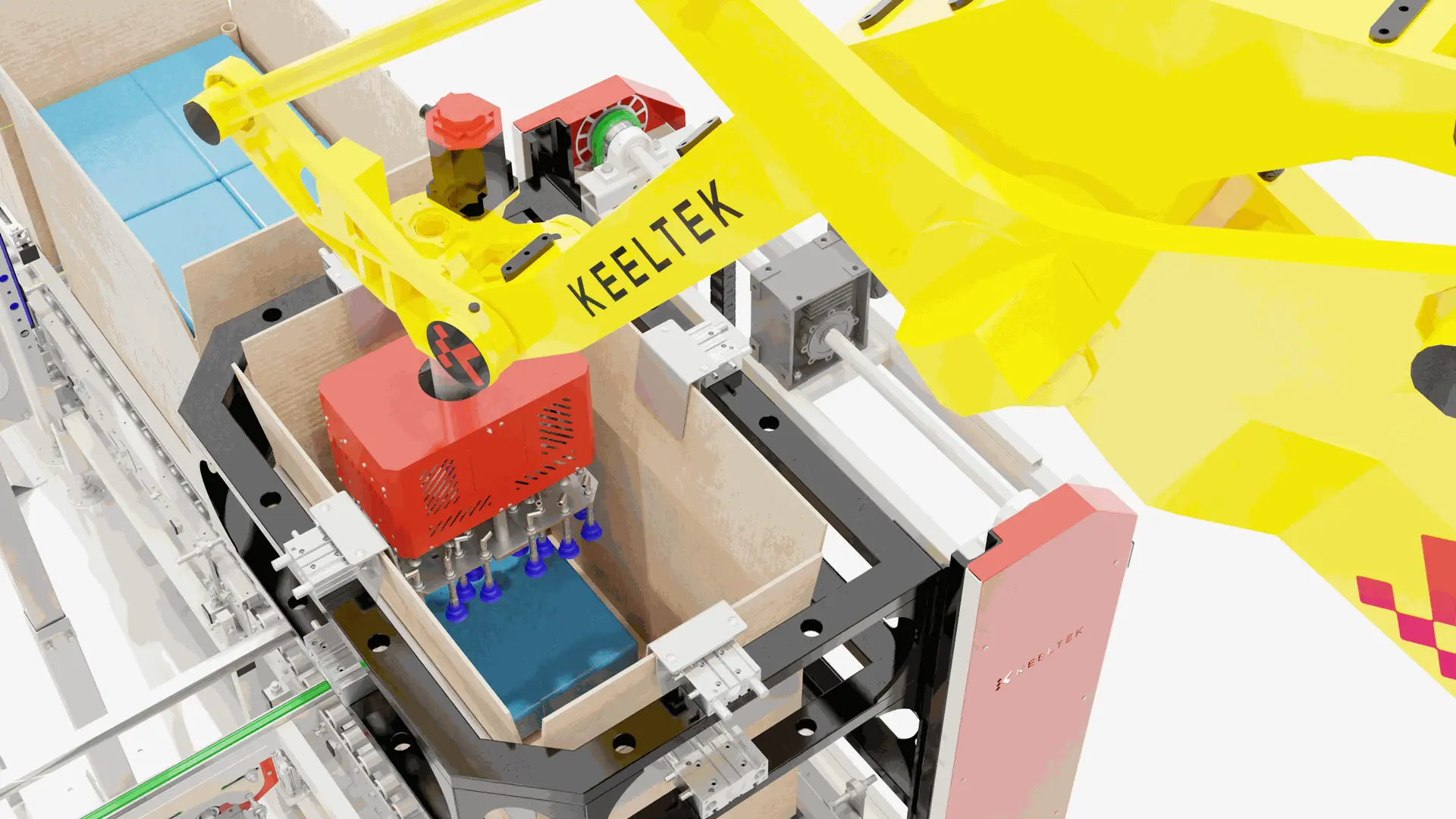

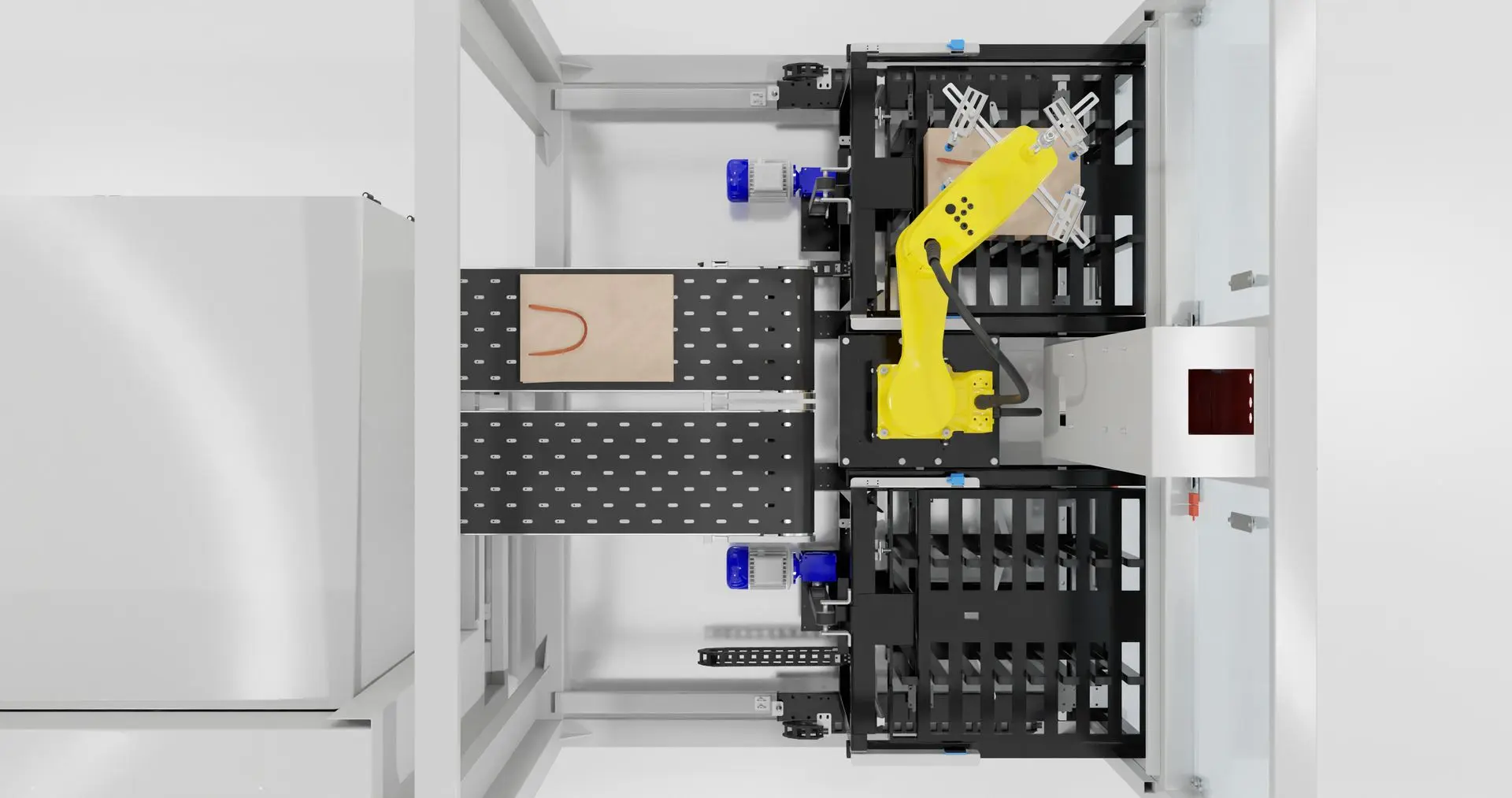

BRIOPACKER

Robotic packing cell

Robotic cell for packing or filling multiple containers with products of any kind

BRIOPACKER

Robotic packing cell

Robotic cell for packing or filling multiple containers with products of any kind

BRIOPACKER

Robotic packing cell

Robotic cell for packing or filling multiple containers with products of any kind

BRIOPACKER

Robotic packing cell

Robotic cell for packing or filling multiple containers with products of any kind

BRIOPACKER

Robotic packing cell

Robotic cell for packing or filling multiple containers with products of any kind

| Reference Product | Depending on application. (Boxes, bins, blister packs, bags, nets, packages, etc.) |

| Maximum permissible load | Consult. |

| Connectivity | LAN. |

| Cadences | Up to 10 pickings/minute |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

- Different options depending on application.

- KTS, remote assistance.

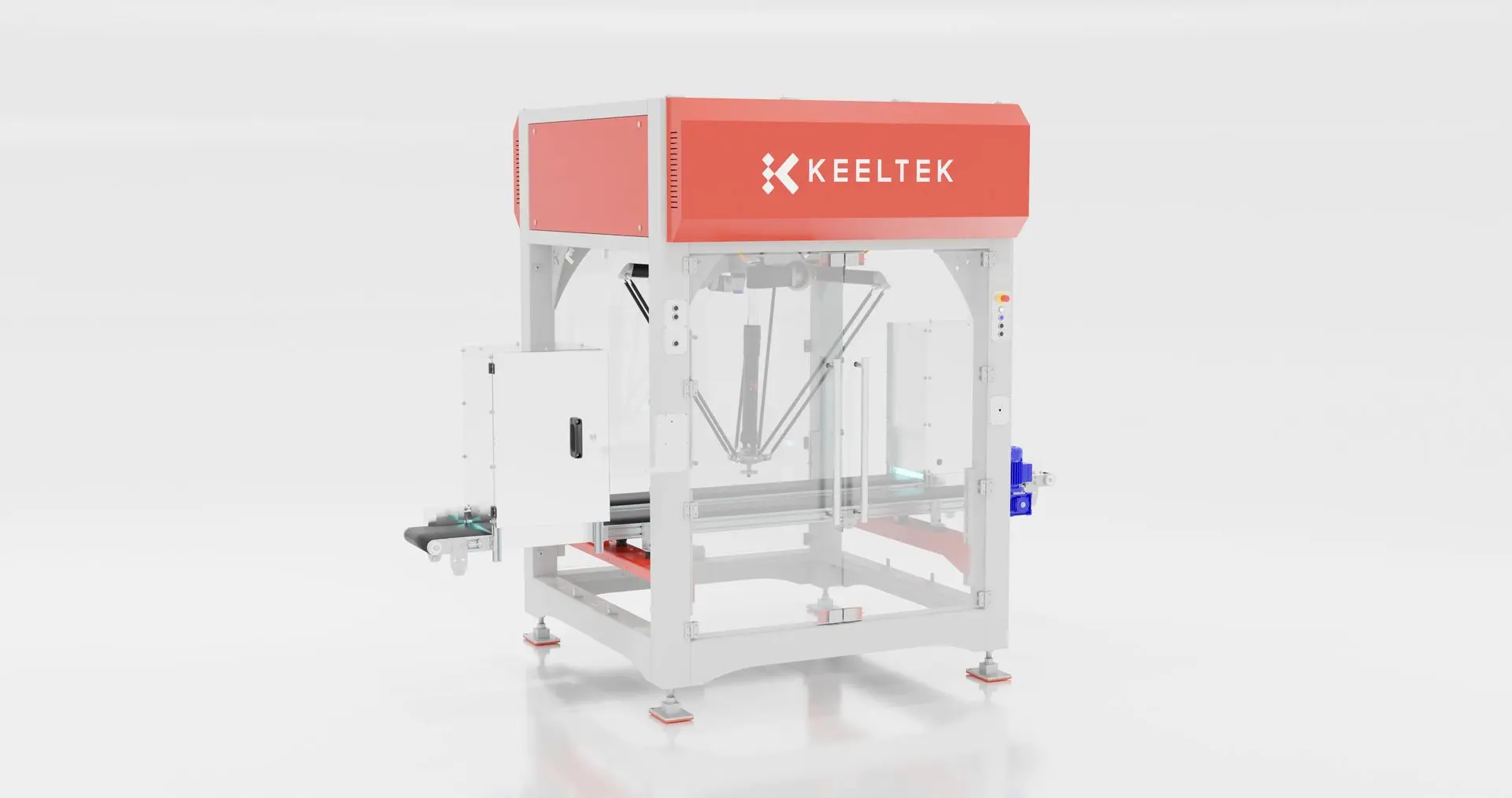

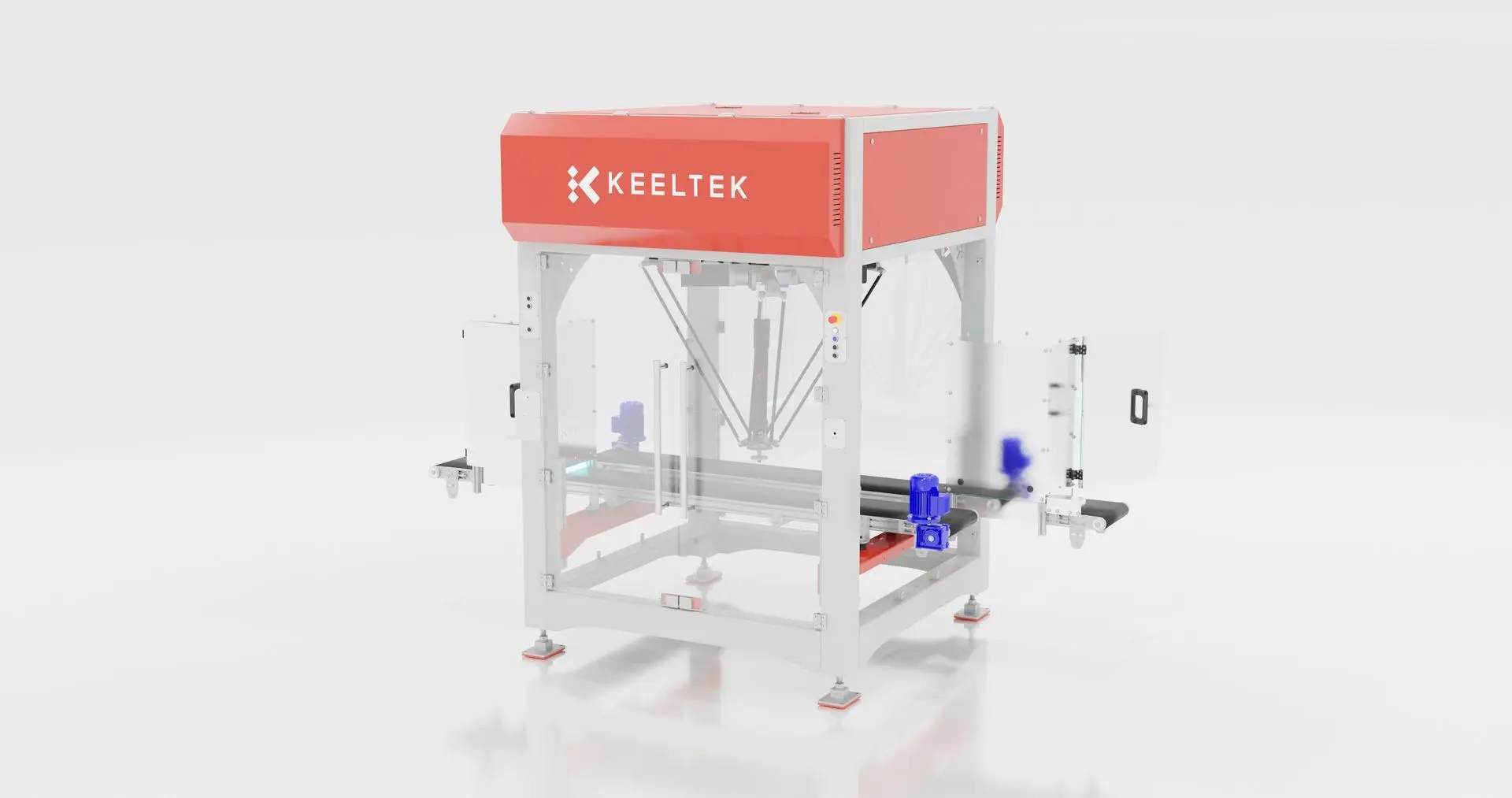

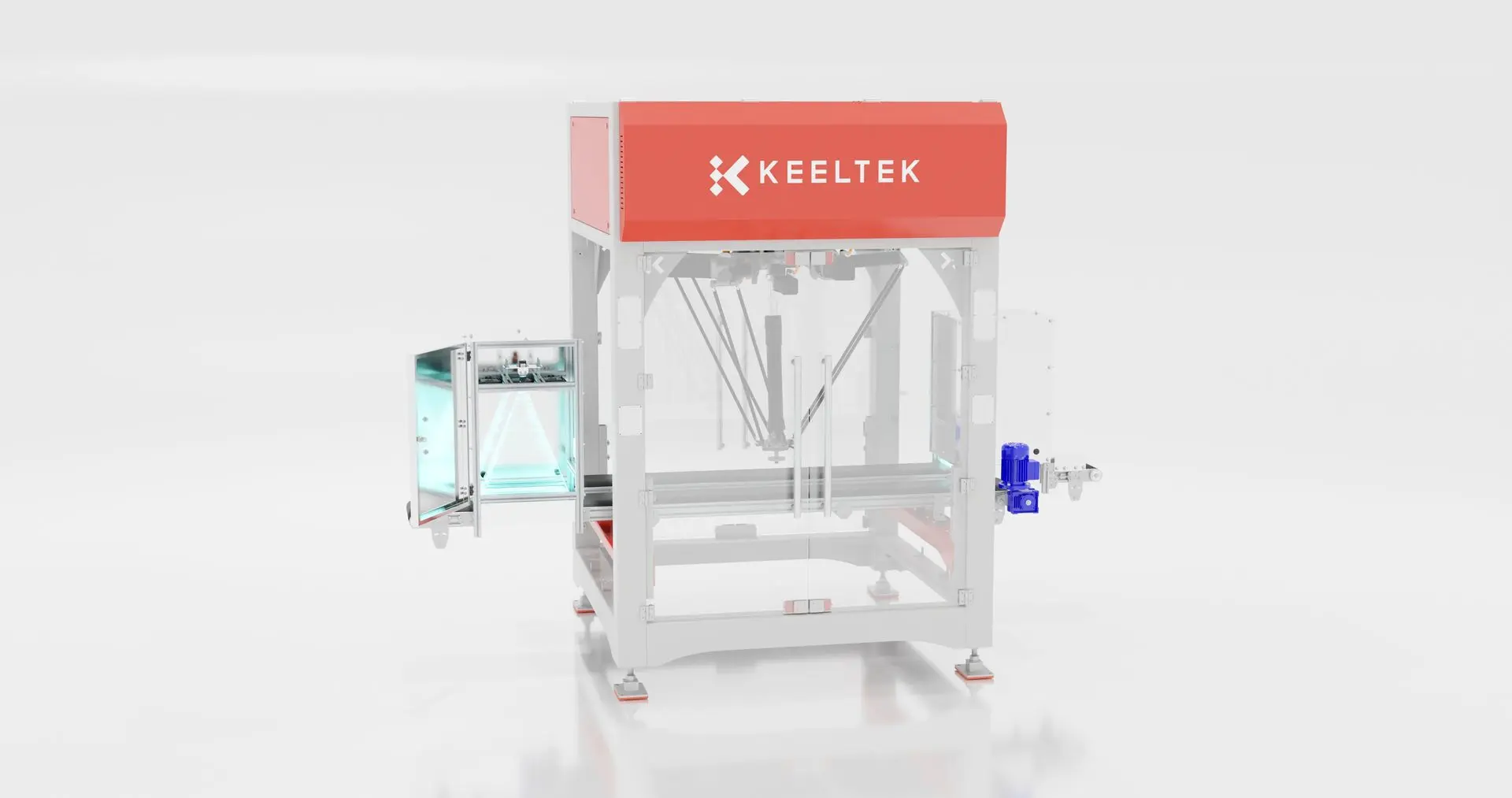

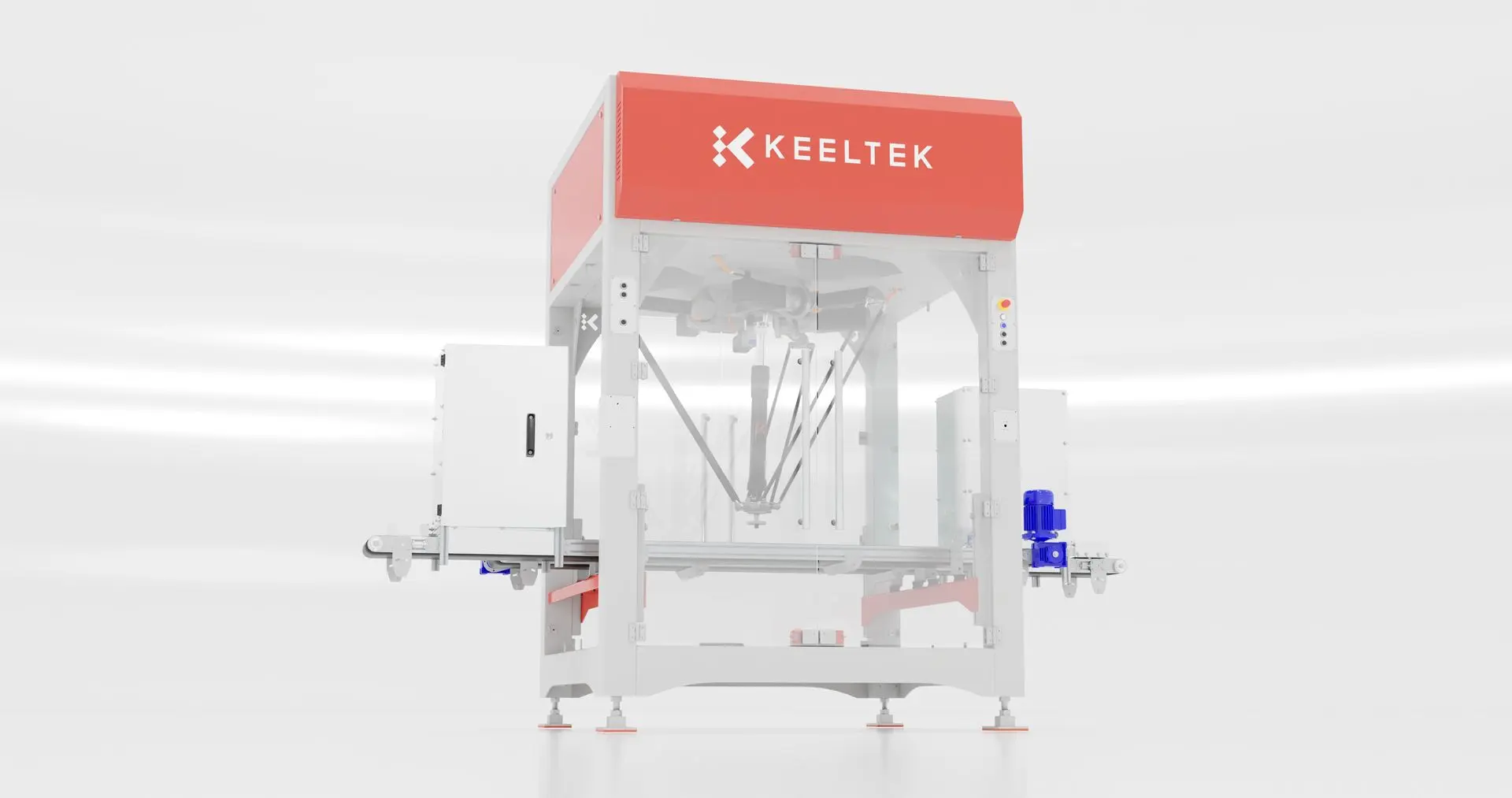

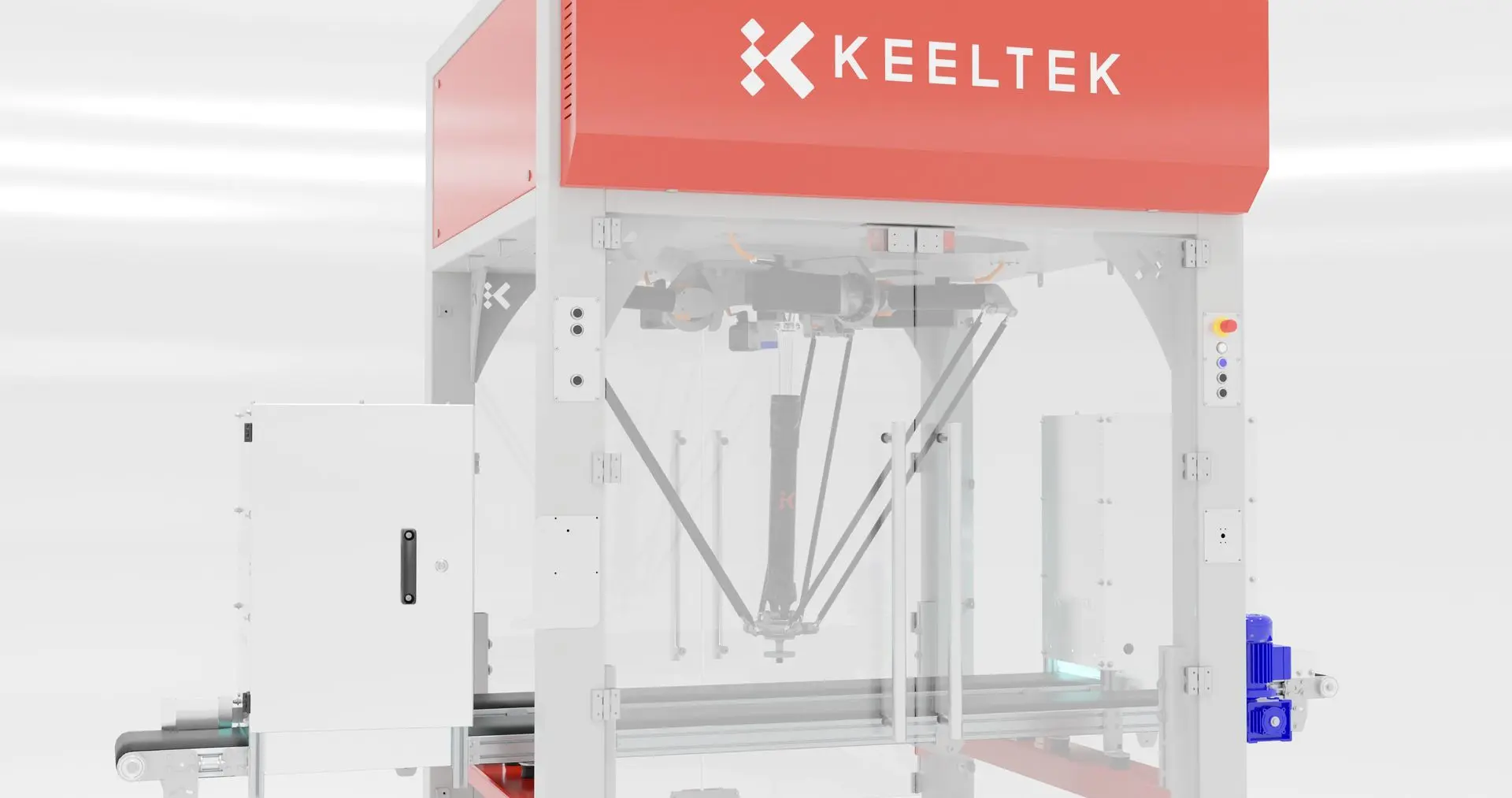

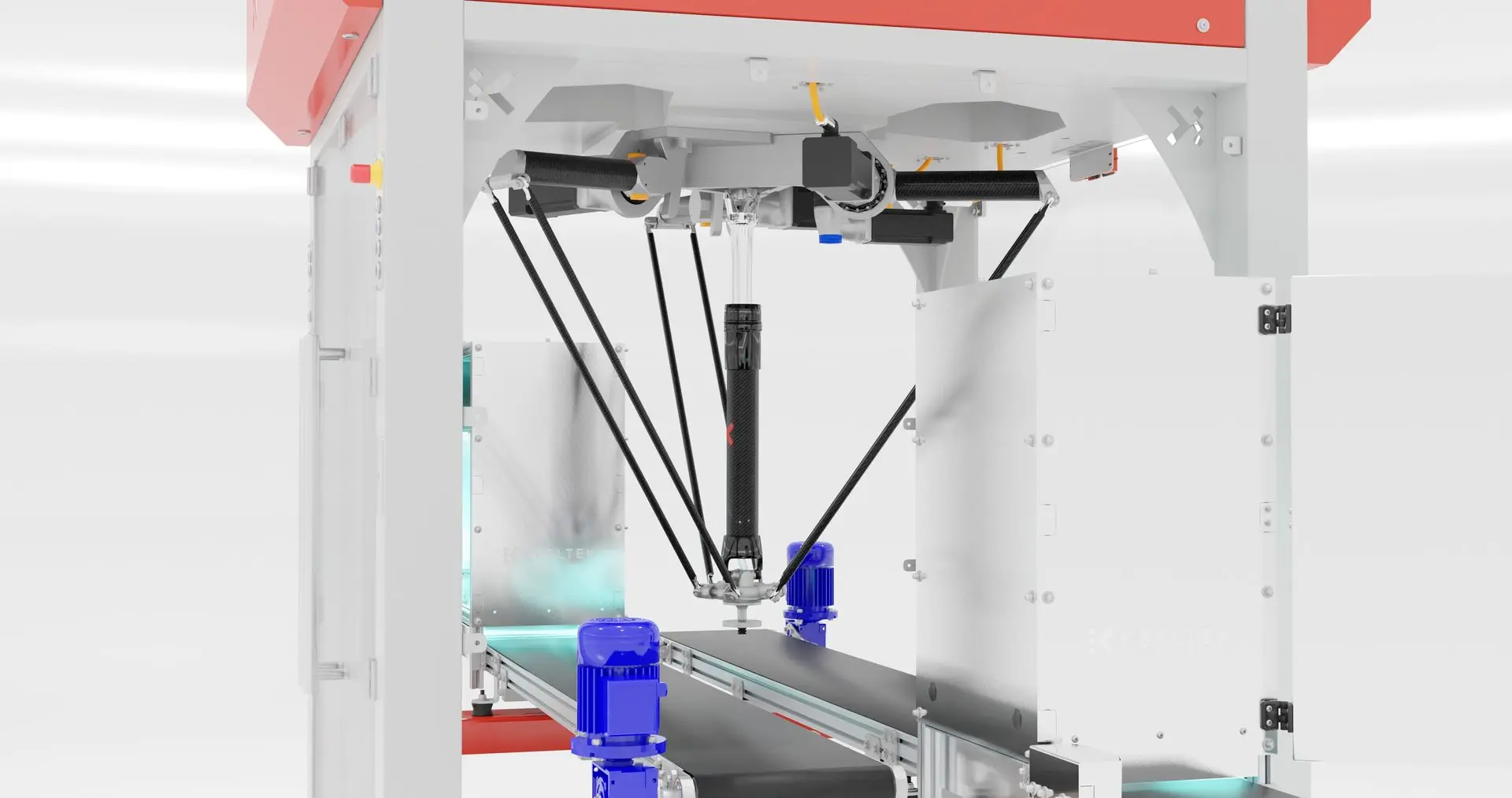

ACCUFAST DELTA

DELTA-type robotic cell

Robotic cell equipped with DELTA-type robot for high-speed pick-and-place applications with maximum precision

ACCUFAST DELTA

DELTA-type robotic cell

Robotic cell equipped with DELTA-type robot for high-speed pick-and-place applications with maximum precision

ACCUFAST DELTA

DELTA-type robotic cell

Robotic cell equipped with DELTA-type robot for high-speed pick-and-place applications with maximum precision

ACCUFAST DELTA

DELTA-type robotic cell

Robotic cell equipped with DELTA-type robot for high-speed pick-and-place applications with maximum precision

ACCUFAST DELTA

DELTA-type robotic cell

Robotic cell equipped with DELTA-type robot for high-speed pick-and-place applications with maximum precision

ACCUFAST DELTA

DELTA-type robotic cell

Robotic cell equipped with DELTA-type robot for high-speed pick-and-place applications with maximum precision

Dimensions | Depending ont he application |

| Reference Product | Any type of product (cosmetics, fruit, pastries, etc.) |

| Maximum permissible load | Consult. |

| Connectivity | LAN. |

| Cadences | Up to 100 cycles per minute per installed module. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

- Automatic tool change

- KTS, remote assistance.

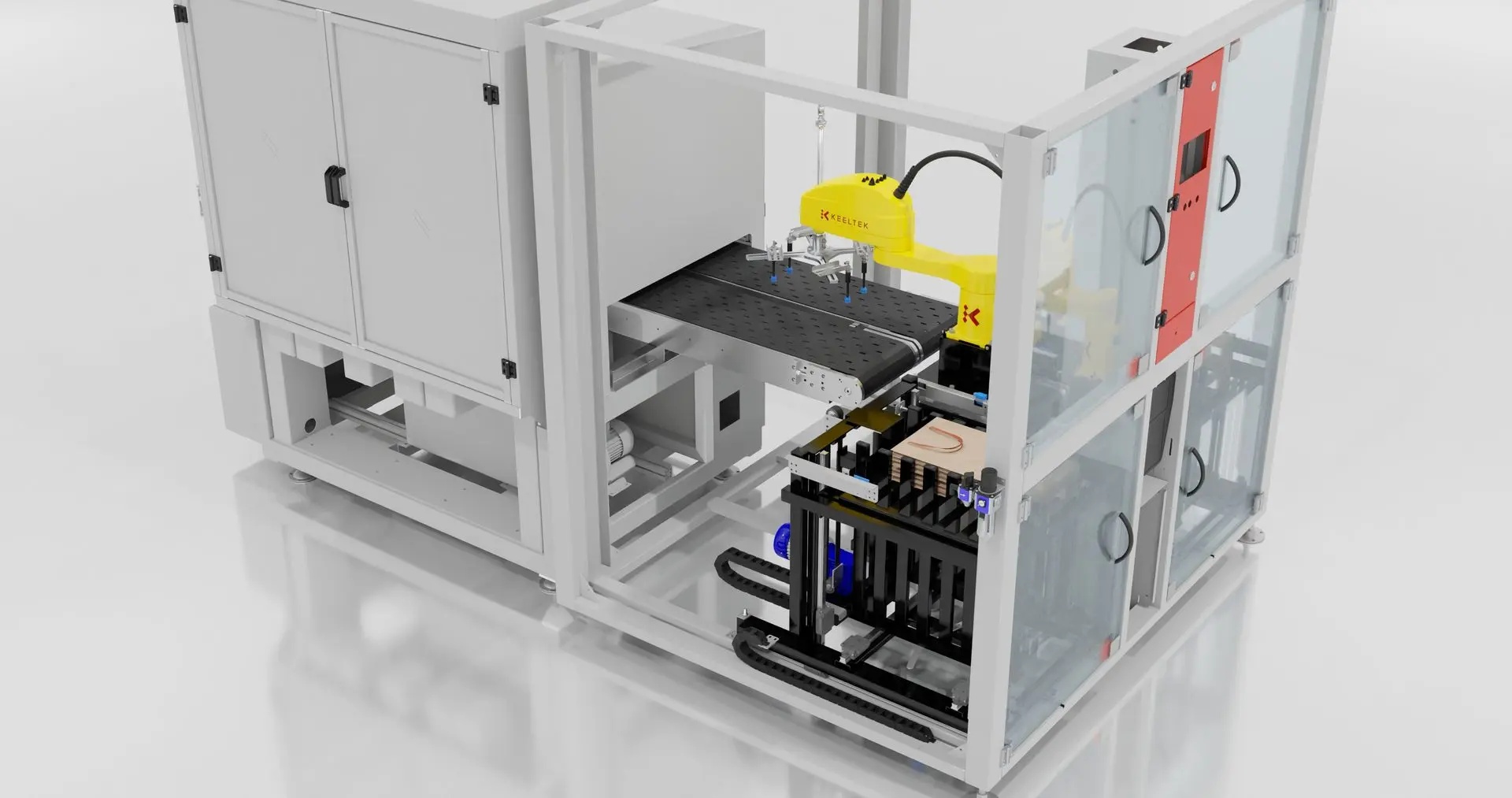

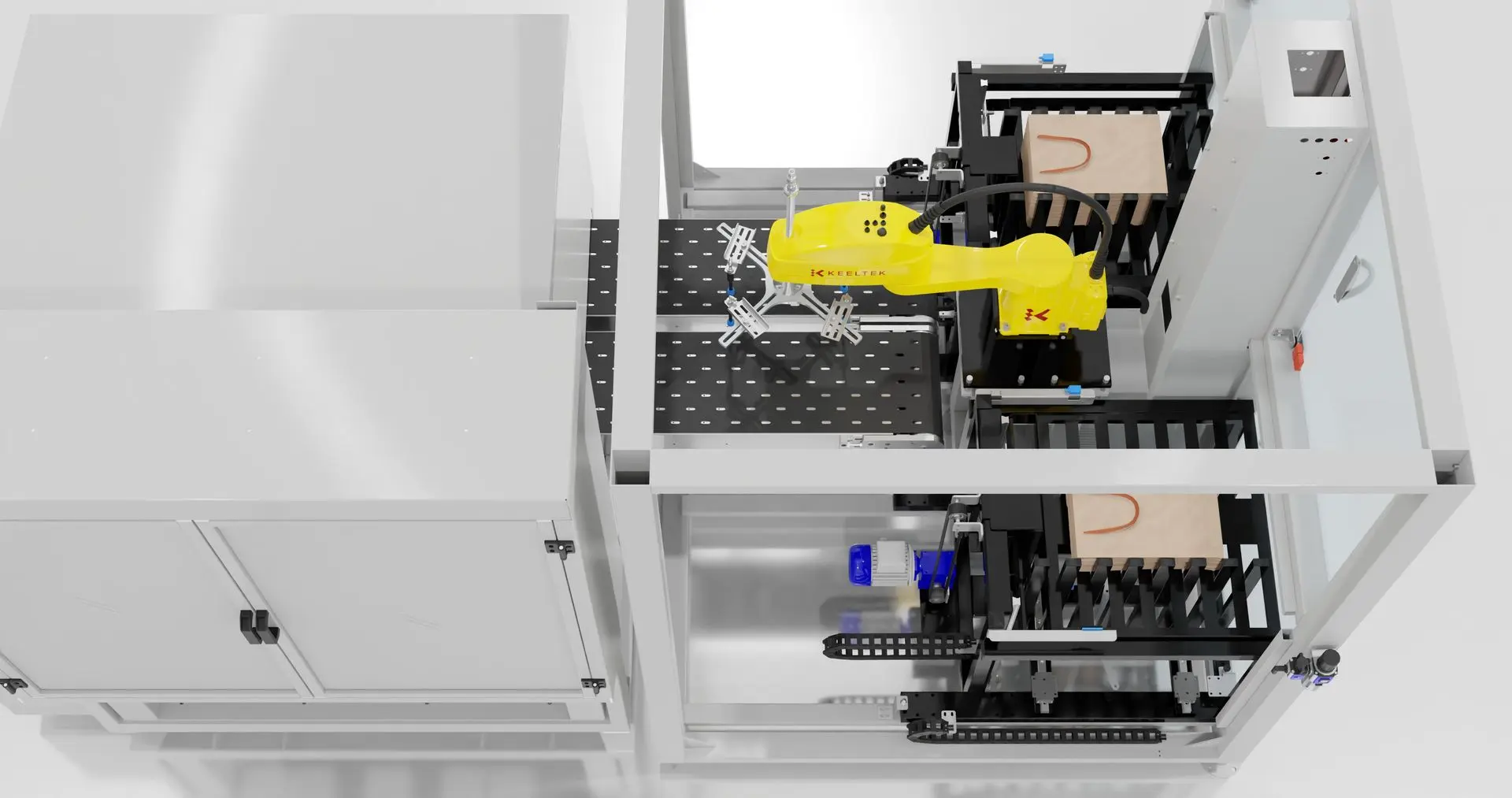

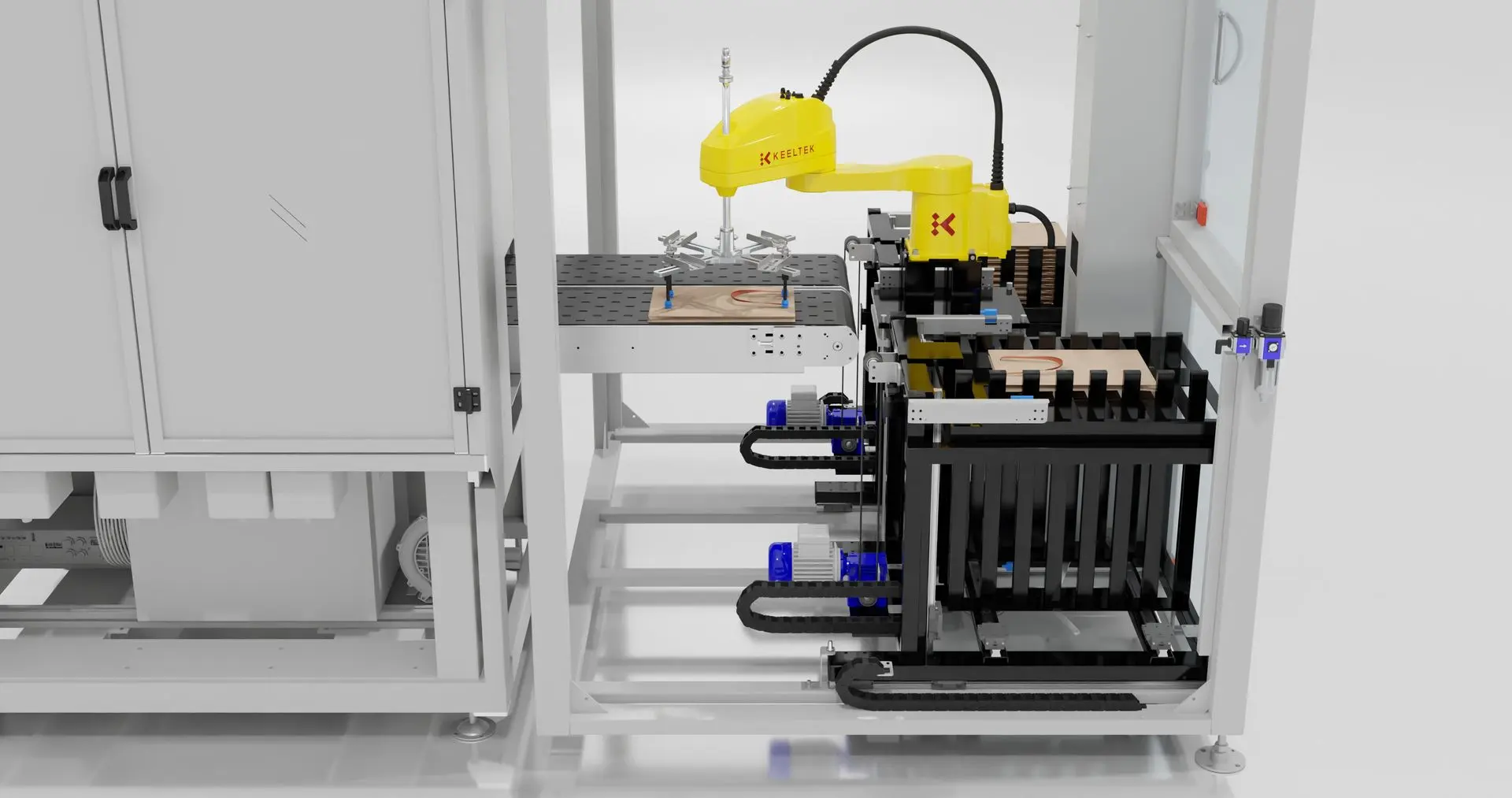

ACCUFAST SCARA

SCARA-type robotic cell

Robotic cell equipped with SCARA robot for high-speed pick-and-place applications with maximum precision.

ACCUFAST SCARA

SCARA-type robotic cell

Robotic cell equipped with SCARA robot for high-speed pick-and-place applications with maximum precision.

ACCUFAST SCARA

SCARA-type robotic cell

Célula robotizada equipada con robot tipo SCARA para aplicaciones de pick&place con alta cadencia y máxima precisión

ACCUFAST SCARA

SCARA-type robotic cell

Célula robotizada equipada con robot tipo SCARA para aplicaciones de pick&place con alta cadencia y máxima precisión

ACCUFAST SCARA

SCARA-type robotic cell

Célula robotizada equipada con robot tipo SCARA para aplicaciones de pick&place con alta cadencia y máxima precisión

Dimensions | Depending on the application |

| Reference product | Any type of product (cosmetics, fruit, pastries, etc.) |

| Maximum permissible load | Consult. |

| Connectivity | LAN. |

| Cadences | Up to 80 cycles per minute per installed module. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

- Automatic tool change.

- KTS, remote assistance.

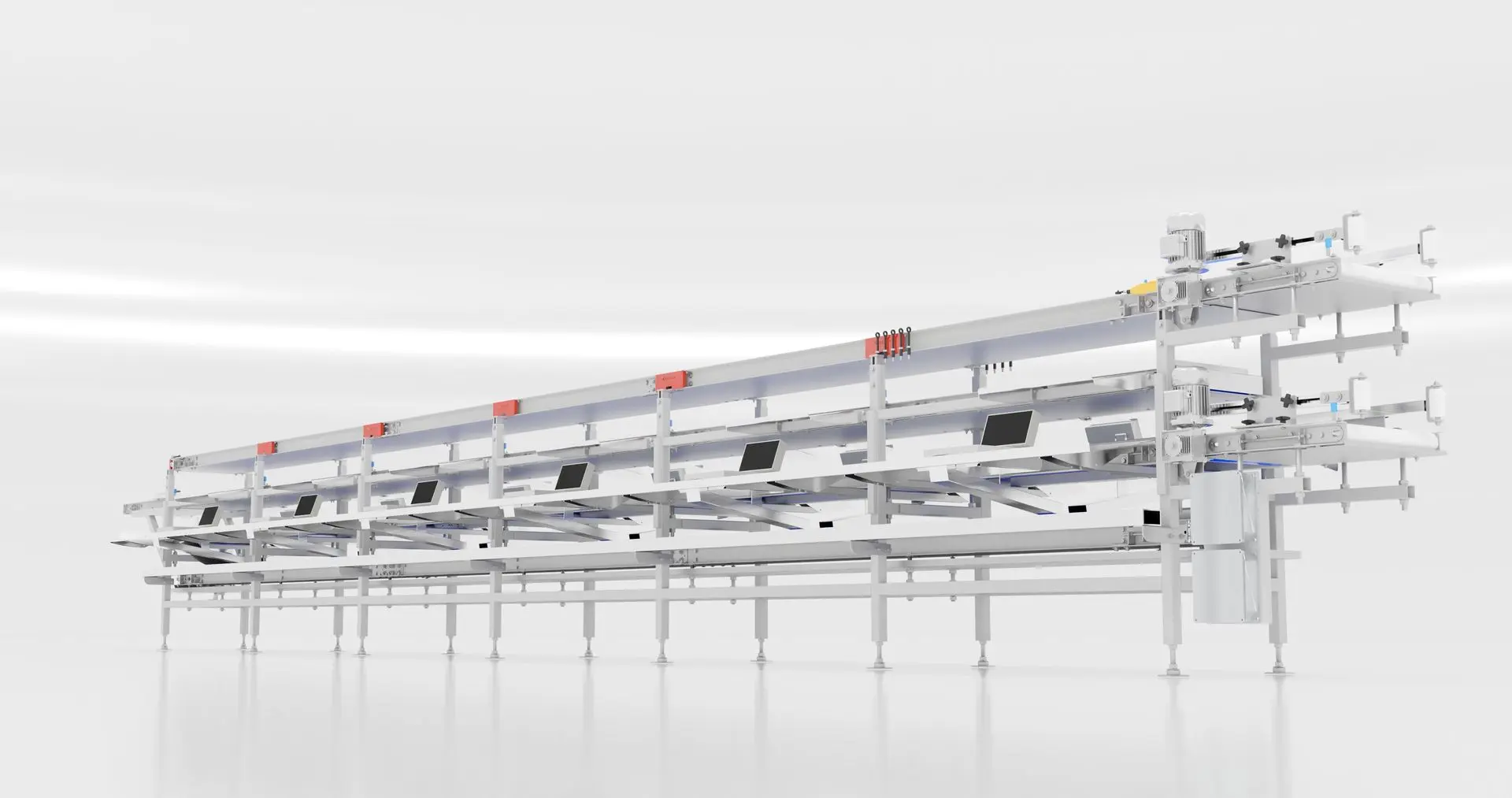

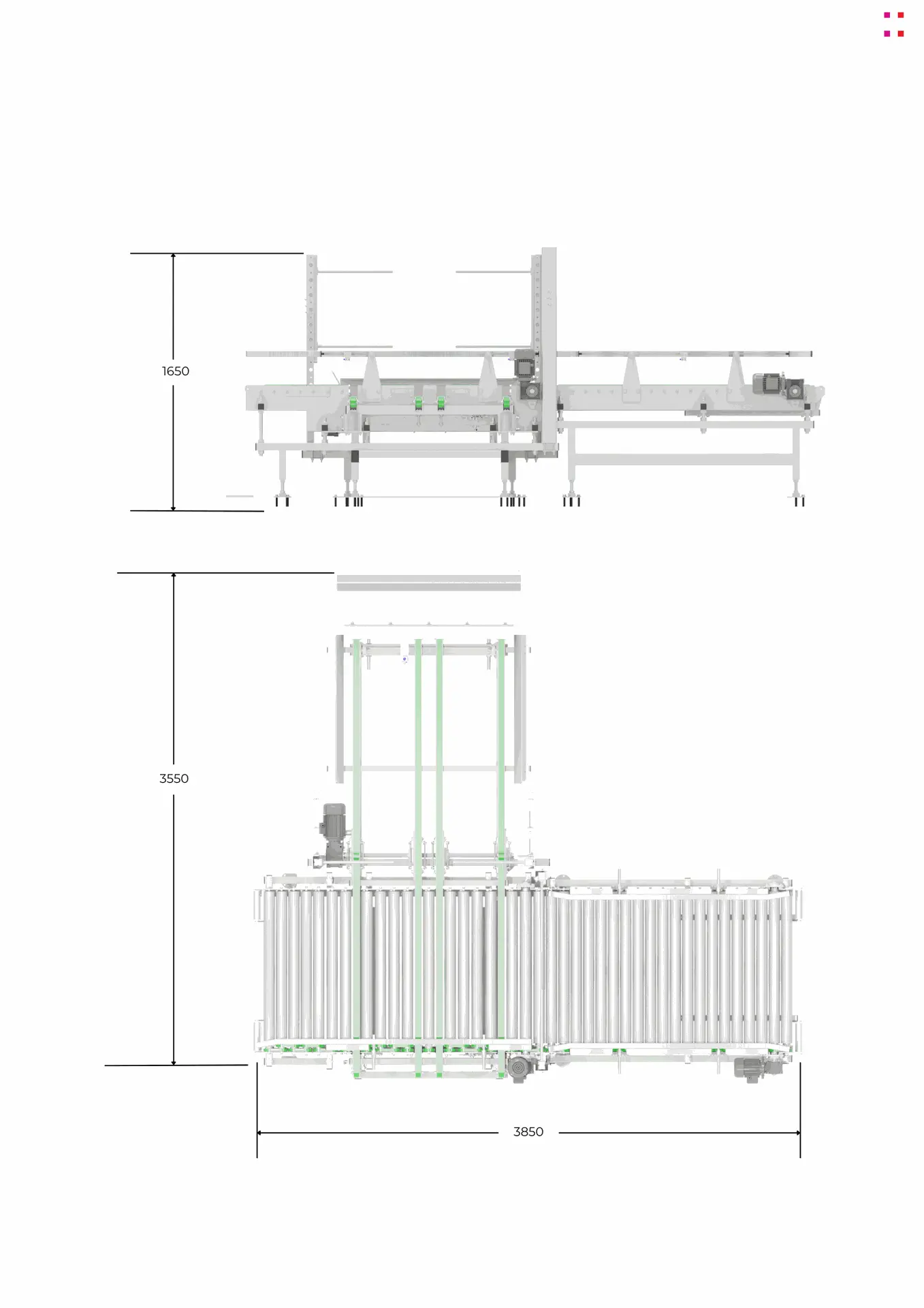

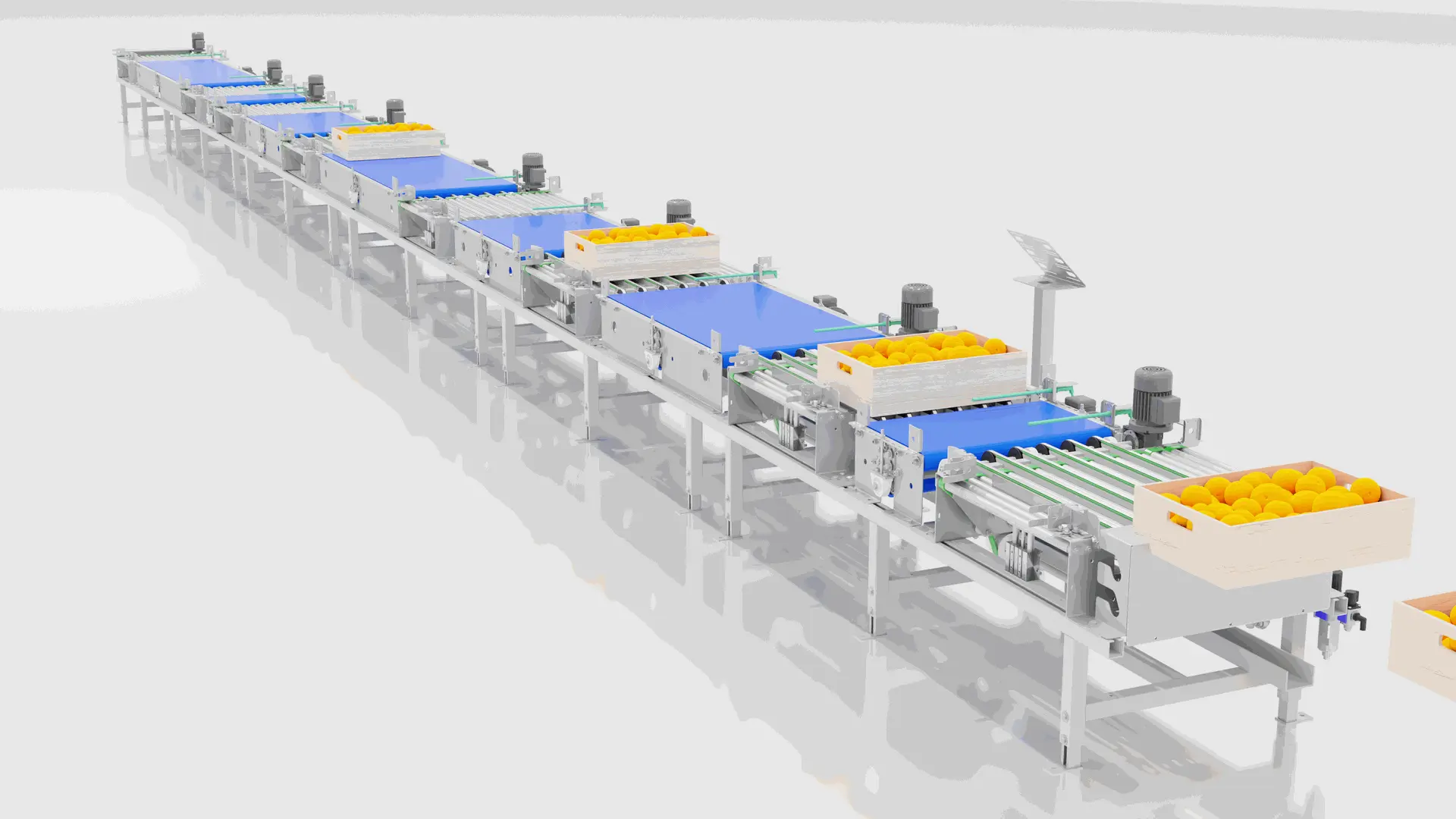

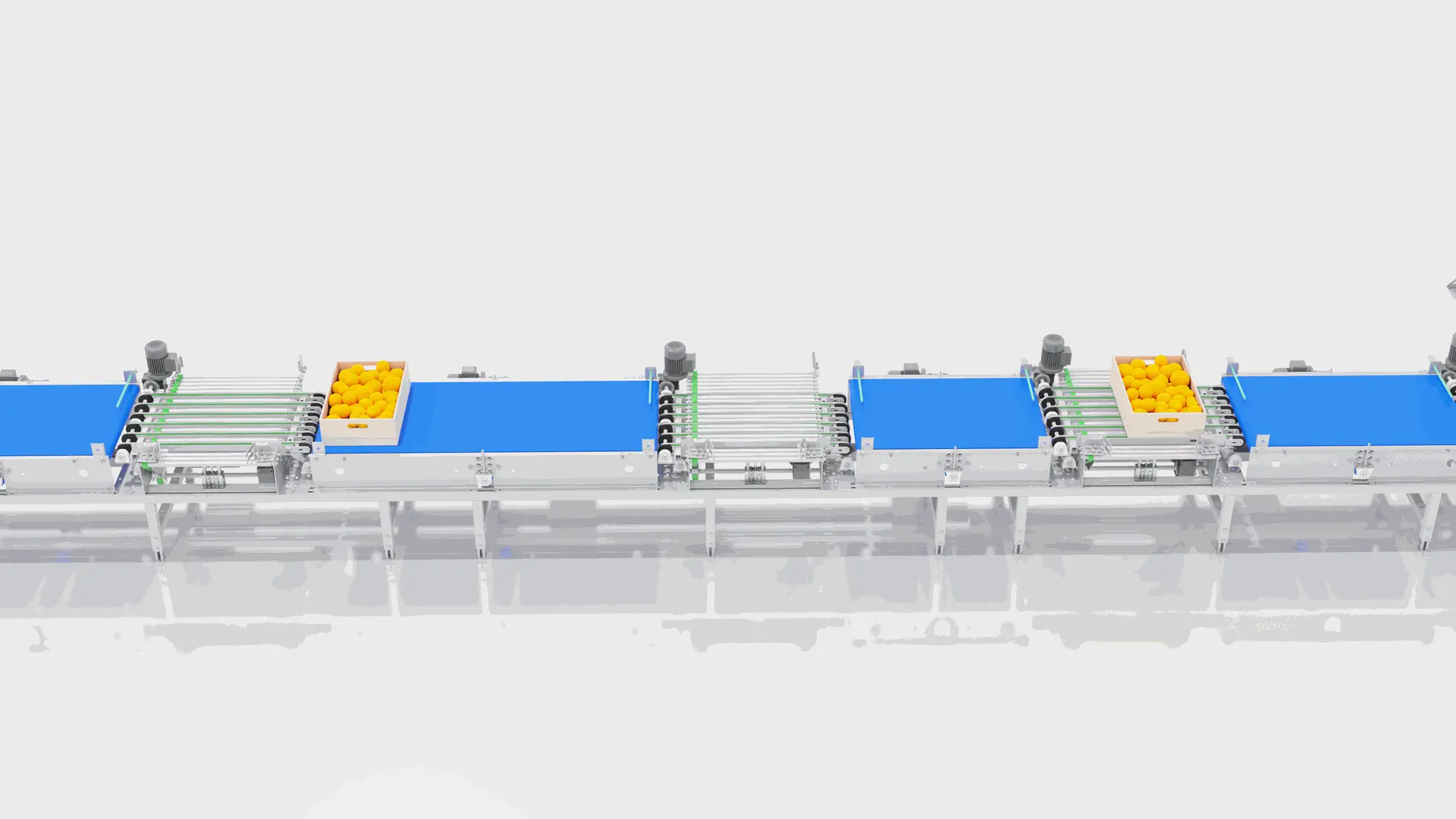

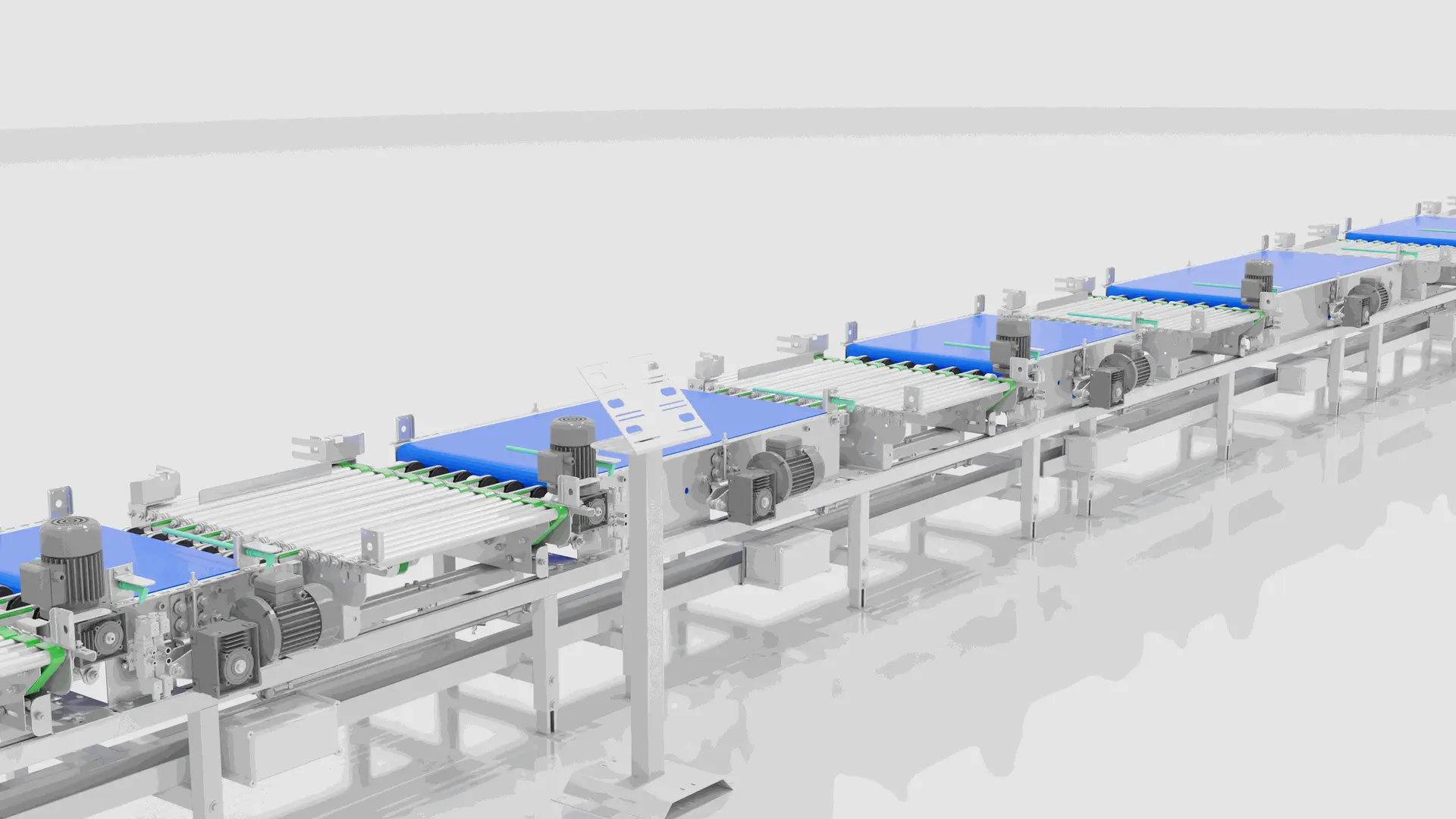

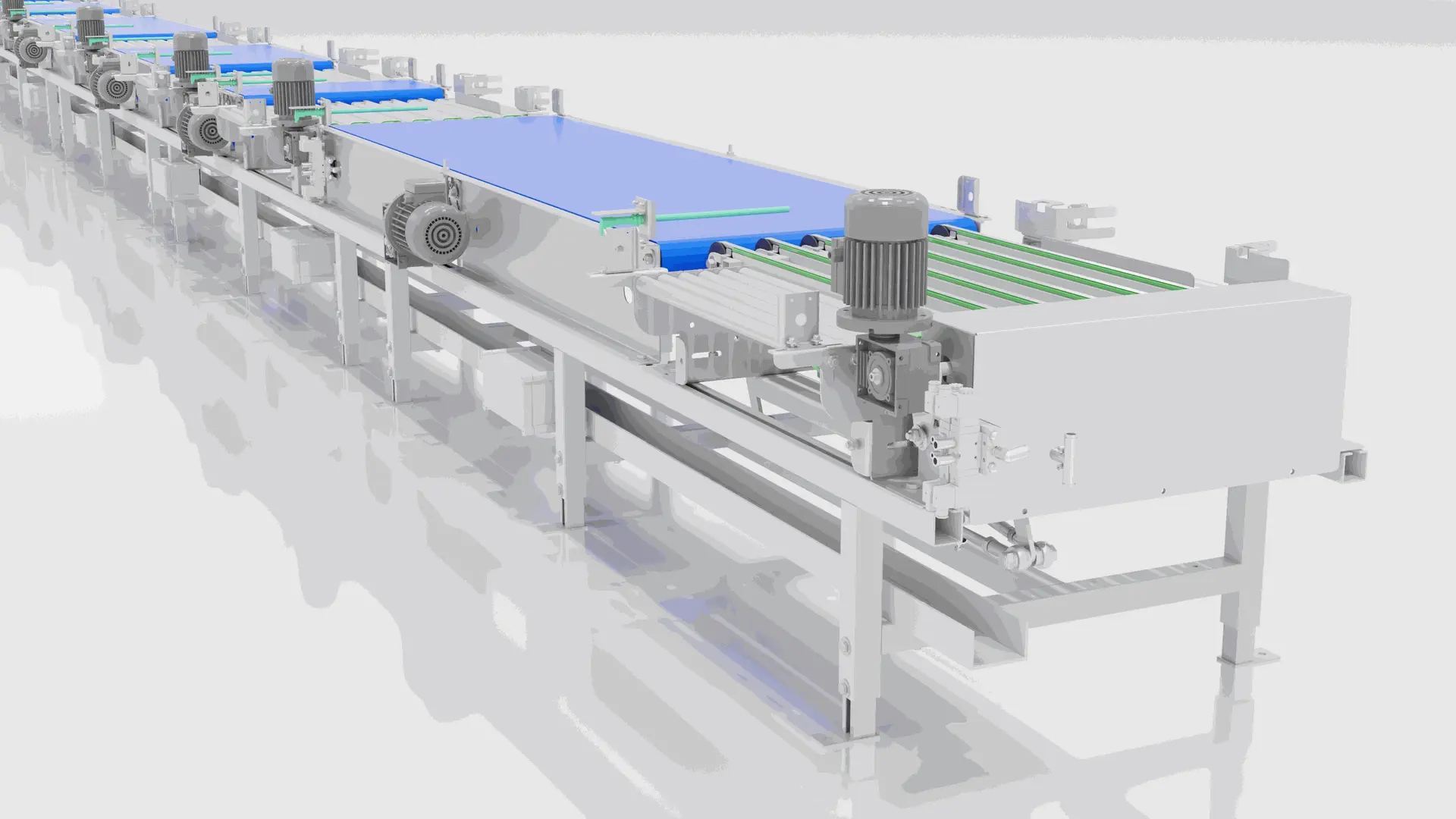

MANPACKER

Semi-automatic repacking line

Semi-automatic line with manual control stations for repacking products.

MANPACKER

Semi-automatic repacking line

Semi-automatic line with manual control stations for repacking products.

MANPACKER

Semi-automatic repacking line

Semi-automatic line with manual control stations for repacking products.

MANPACKER

Semi-automatic repacking line

Semi-automatic line with manual control stations for repacking products.

MANPACKER

Semi-automatic repacking line

Semi-automatic line with manual control stations for repacking products.

| Reference Product | Any type of product in boxes that can be checked for weight, color, or other characteristics. |

| Number of control weights |

Configurable. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed using laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Acabados combinados en Poliuretano de dos componentes, pintura epoxi, galvanizado y/o acero inoxidable.

-

Different levels of machine automation.

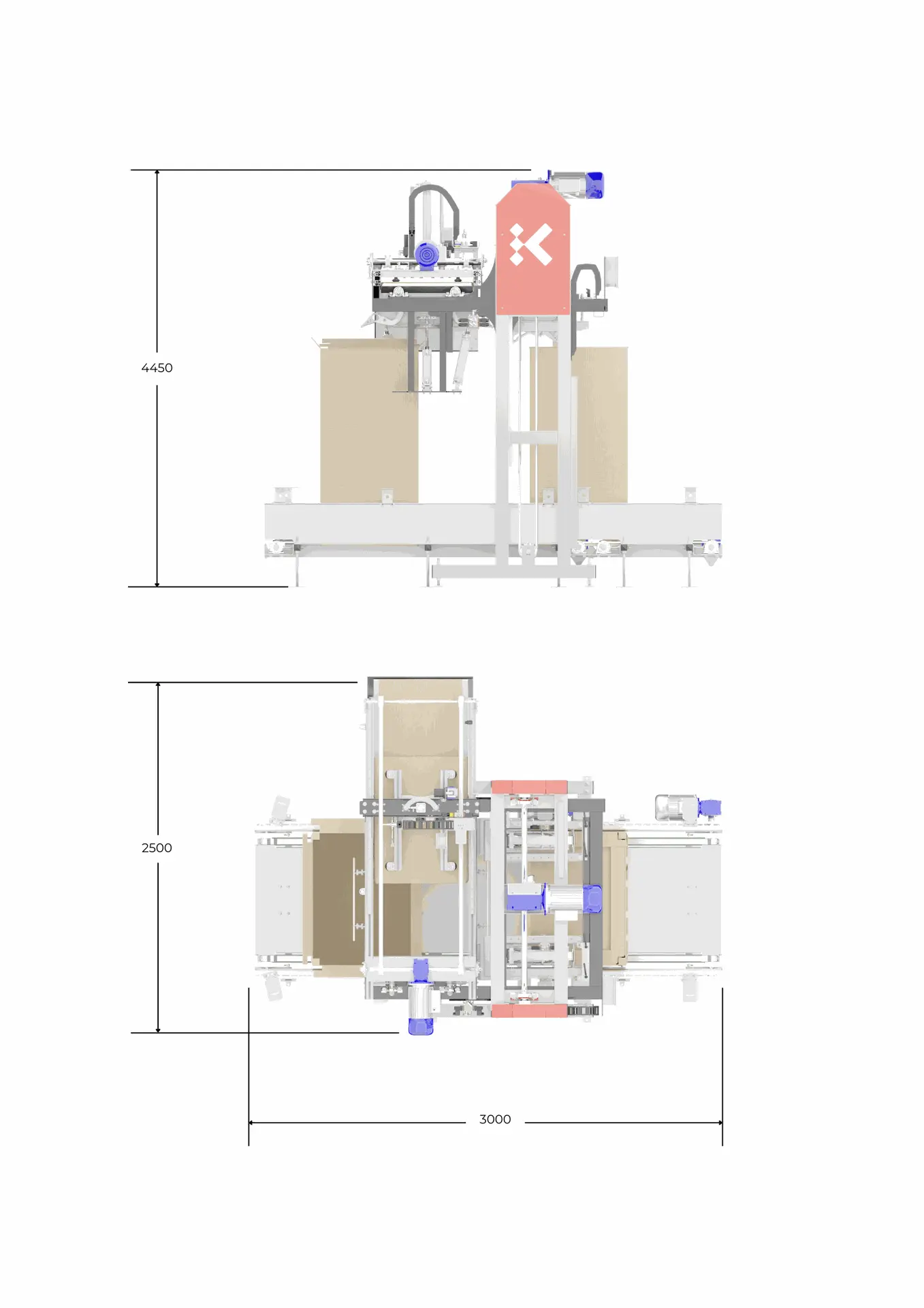

FLAPFOLD

Flap folding and sealing station

Folding and sealing line for flaps on cardboard boxes filled with product.

FLAPFOLD

Flap folding and sealing station

Folding and sealing line for flaps on cardboard boxes filled with product.

FLAPFOLD

Flap folding and sealing station

Folding and sealing line for flaps on cardboard boxes filled with product.

FLAPFOLD

Flap folding and sealing station

Folding and sealing line for flaps on cardboard boxes filled with product.

FLAPFOLD

Flap folding and sealing station

Folding and sealing line for flaps on cardboard boxes filled with product.

| Reference Product | Boxes measuring 600x800 and heights ranging from 450mm to 1100mm. |

| Application |

800x600 cardboard semi-box filling line with nets for potatoes, citrus fruits, nuts, rice packages, napkins, etc. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed using laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Can be integrated into our Overpack Plus line.

- Possibility of adding an inner cover to the box before folding the flaps.

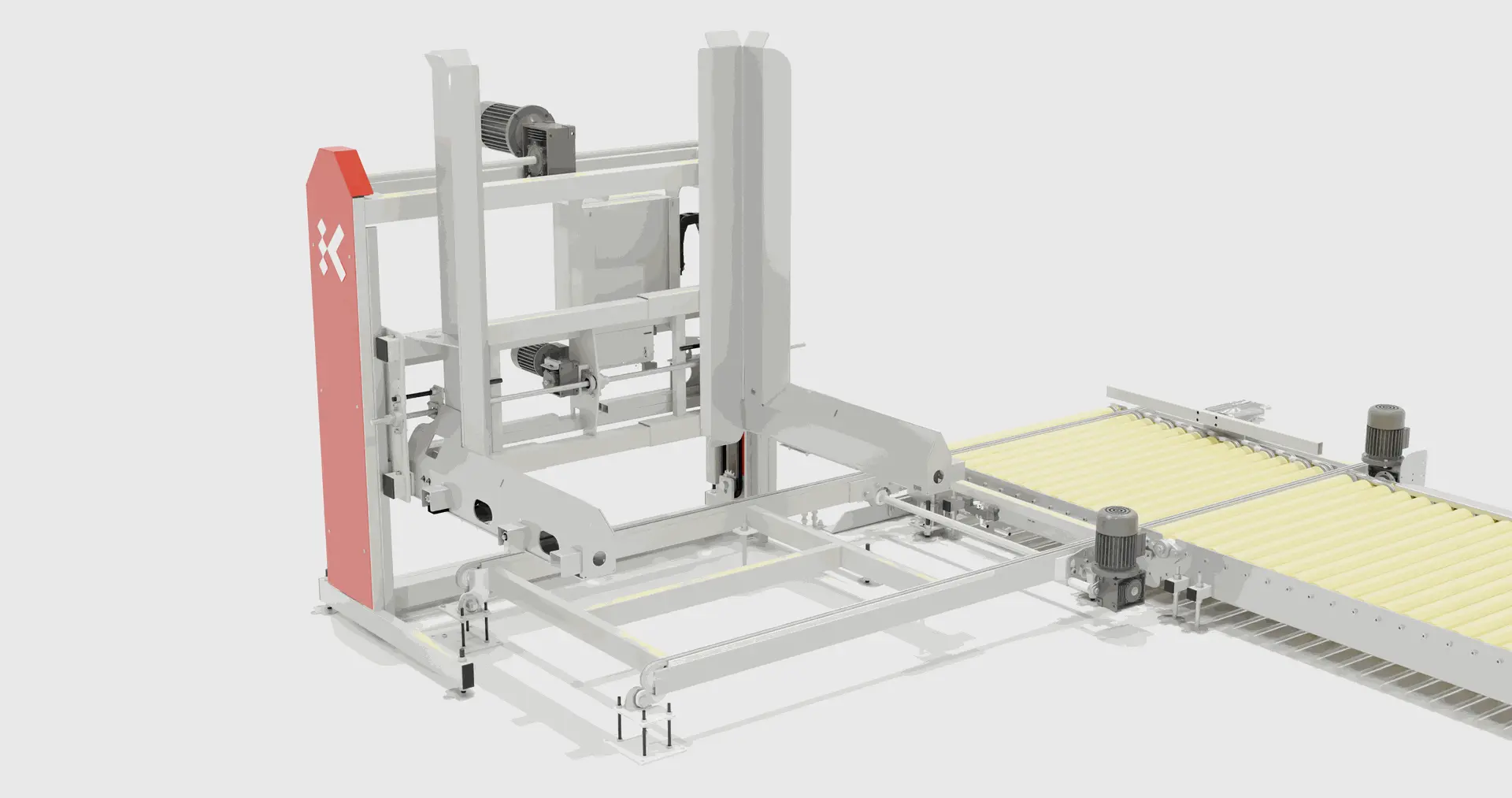

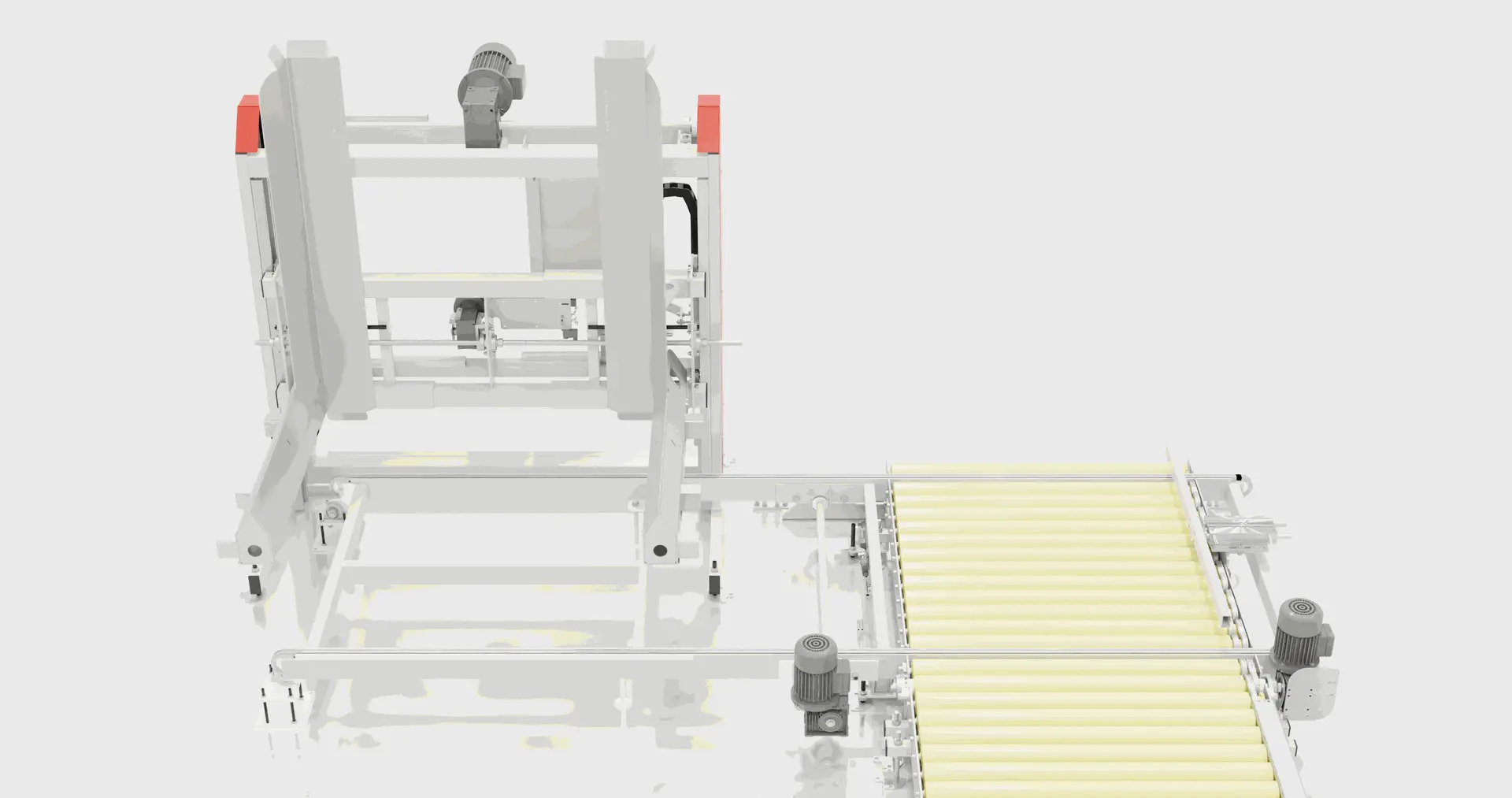

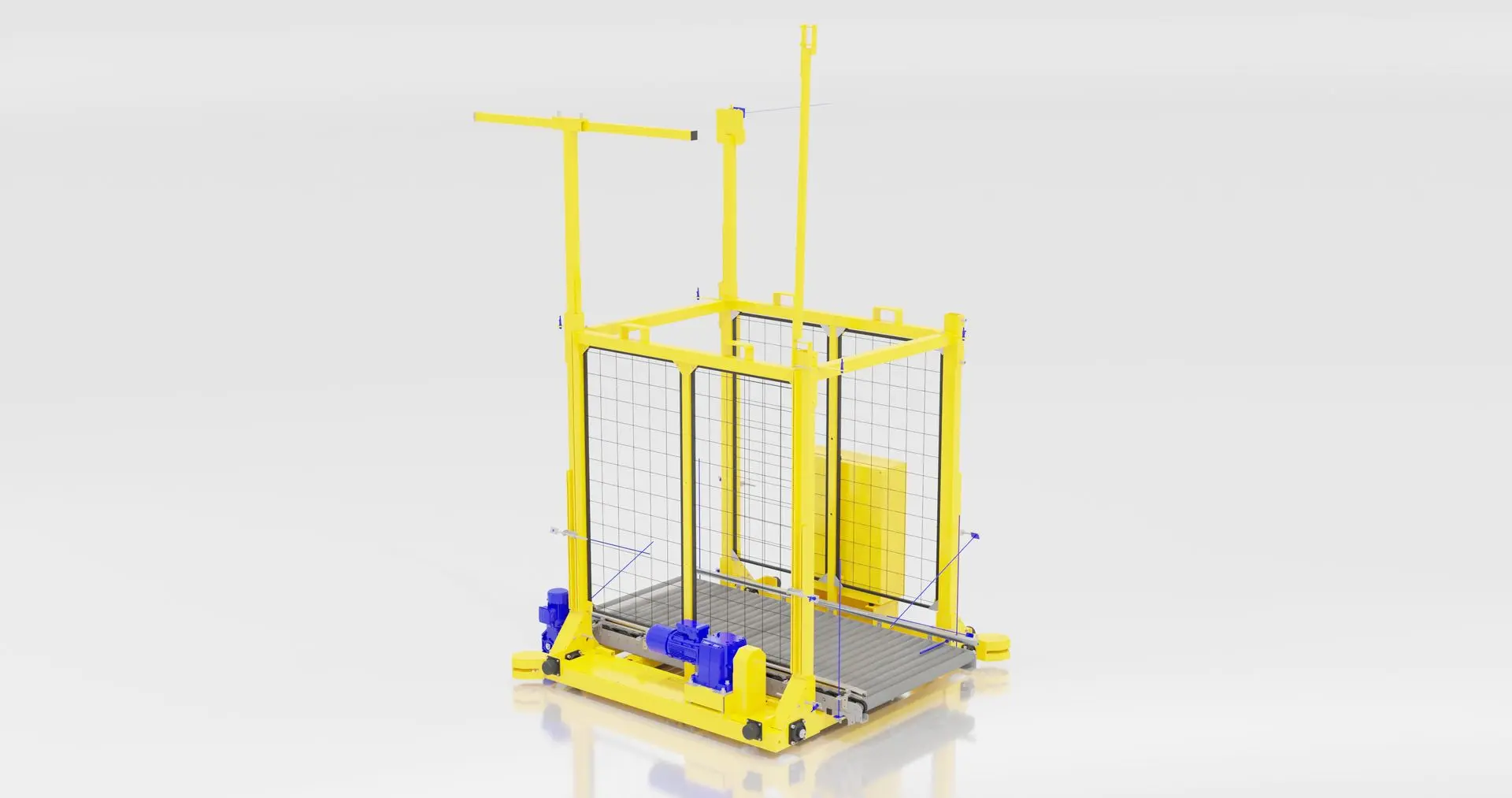

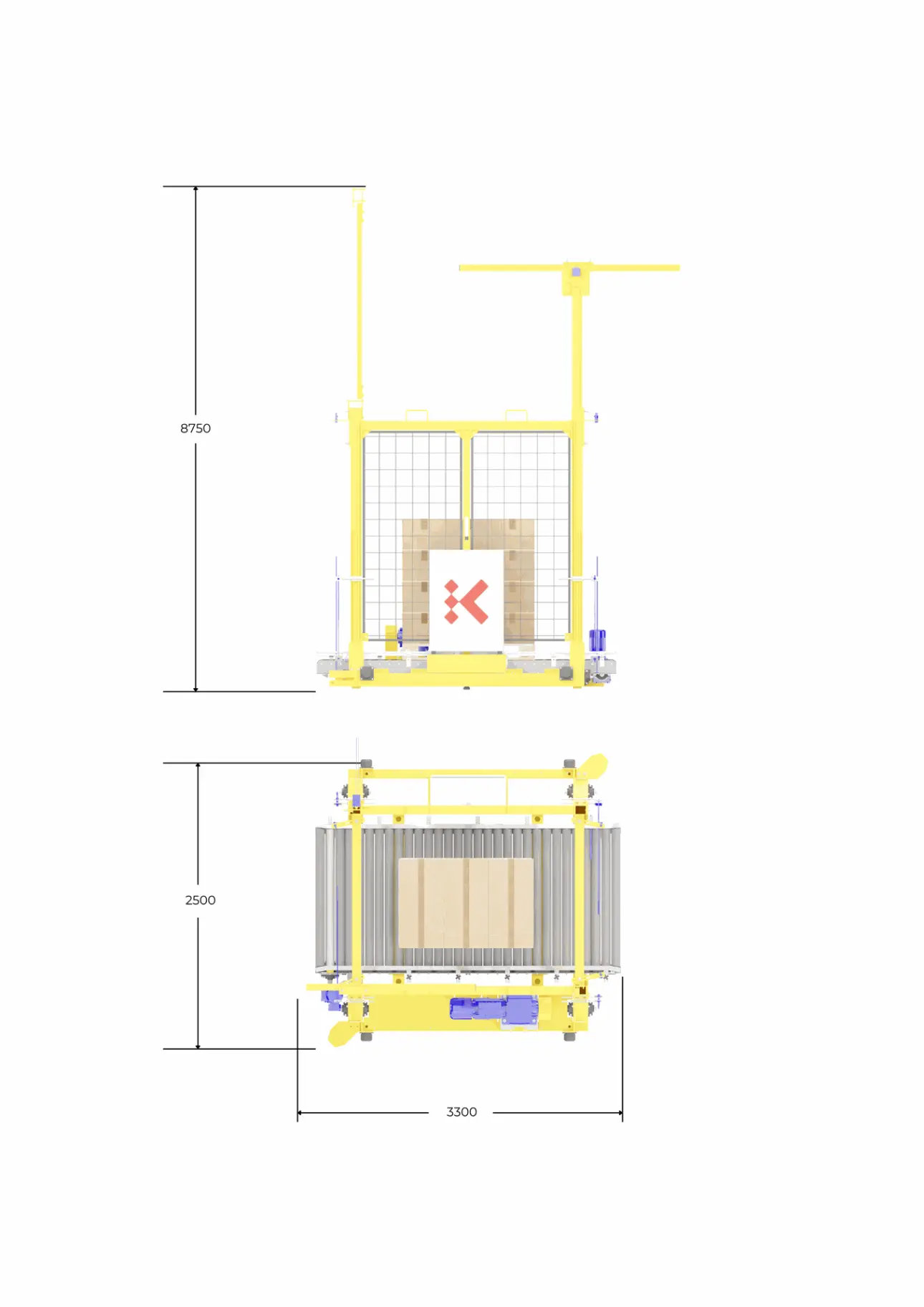

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

| Reference Product | Pallets of different sizes (length, width, and height). |

| Compatibility |

Compatible with any palletizing system. |

Storage capacity | Consult. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed using laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Automatic adjustment to different pallet widths.

- Delivery to laminator, palletizer, etc.

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

| Reference Product | Pallets of different sizes (length, width, and height). |

| Compatibility |

Designed to work in line with DISPALLET. |

|

Integration

|

It can be inserted into any existing line on the pallet passage. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed using laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

-

Paper or other types of materials supplied in rolls can be applied.

WEIGHTSENT DW25E

Weight discriminator up to 25 kg

Automatic dynamic weight discriminator, specially designed for medium-sized boxes. Includes diverter for rejection.

WEIGHTSENT DW25E

Weight discriminator up to 25 kg

Automatic dynamic weight discriminator, specially designed for medium-sized boxes. Includes diverter for rejection.

WEIGHTSENT DW25E

Weight discriminator up to 25 kg

Automatic dynamic weight discriminator, specially designed for medium-sized boxes. Includes diverter for rejection.

WEIGHTSENT DW25E

Weight discriminator up to 25 kg

Automatic dynamic weight discriminator, specially designed for medium-sized boxes. Includes diverter for rejection.

WEIGHTSENT DW25E

Weight discriminator up to 25 kg

Automatic dynamic weight discriminator, specially designed for medium-sized boxes. Includes diverter for rejection.

| Reference Product | Boxes up to 25 kg. |

| Cadences |

Up to 15 units per minute. |

| Resolution |

+- 15 g. |

|

Accuracy |

+- 20 g. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Handling:

- Compact machine that can be easily integrated into the production line.

Regulations:

- Ability to work in food environments.

- Data recording in file.

- Batch control.

- Statistics.

- LAN Connectivity.

- Integration: SCADA, ERP.

WEIGHTSENT DW50E

Weight discriminator for heavy loads

Automatic dynamic weight discriminator, specially designed for pallets and large loads. Includes diverter for rejection.

WEIGHTSENT DW50E

Weight discriminator for heavy loads

Automatic dynamic weight discriminator, specially designed for pallets and large loads. Includes diverter for rejection.

WEIGHTSENT DW50E

Weight discriminator for heavy loads

Automatic dynamic weight discriminator, specially designed for pallets and large loads. Includes diverter for rejection.

WEIGHTSENT DW50E

Weight discriminator for heavy loads

Automatic dynamic weight discriminator, specially designed for pallets and large loads. Includes diverter for rejection.

WEIGHTSENT DW50E

Weight discriminator for heavy loads

Automatic dynamic weight discriminator, specially designed for pallets and large loads. Includes diverter for rejection.

| Reference Product | Pallets/boxes up to 1500 kg. |

| Cadences |

Consult. |

| Resolution |

+- 15 g. |

|

Accuracy |

+- 20 g. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Handling:

- Compact machine that can be easily integrated into the production line

Regulations:

- Ability to work in food environments.

- Data recording in file.

- Batch control.

- Statistics.

- LAN Connectivity.

- Integration: SCADA, ERP.

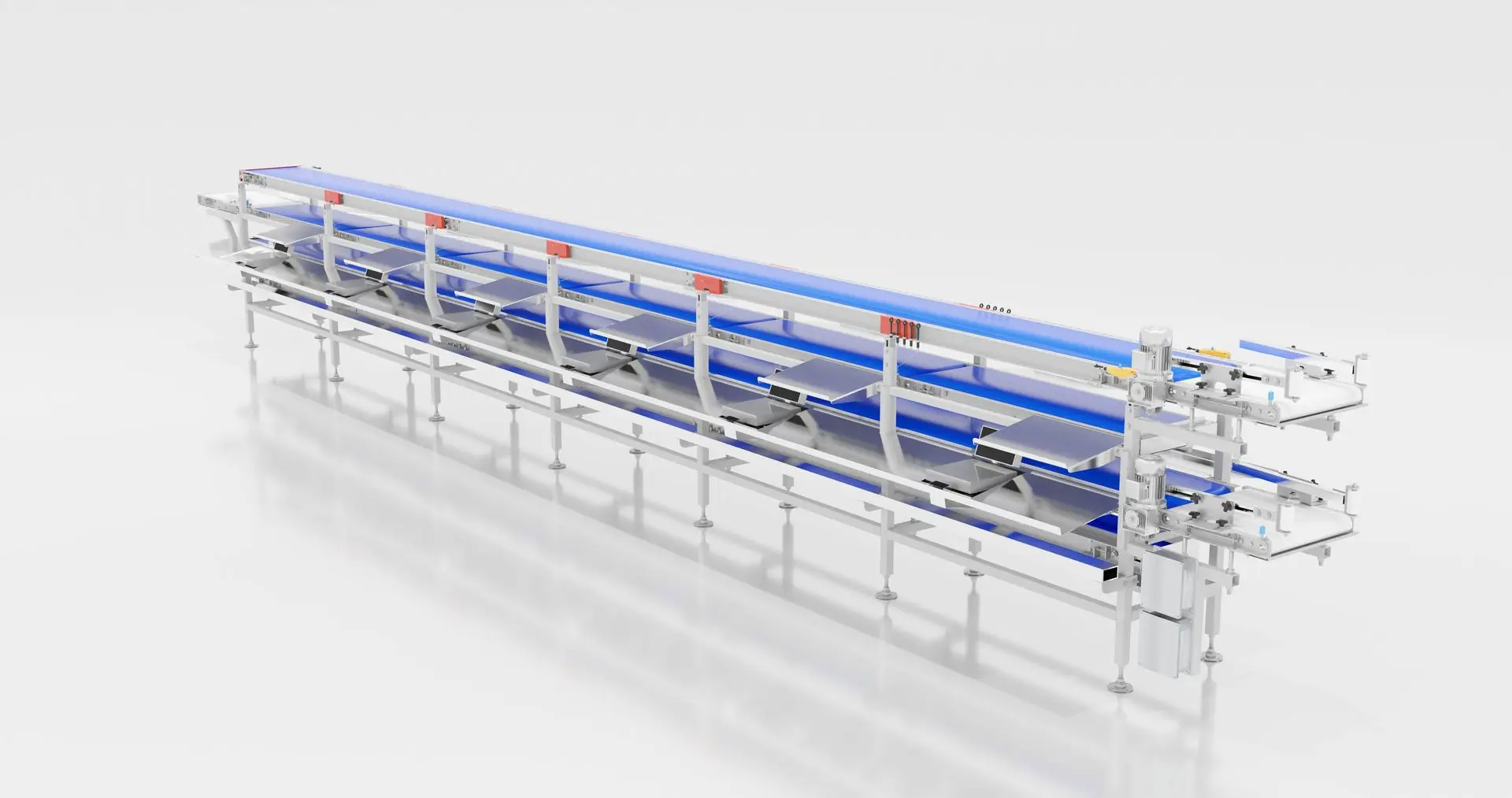

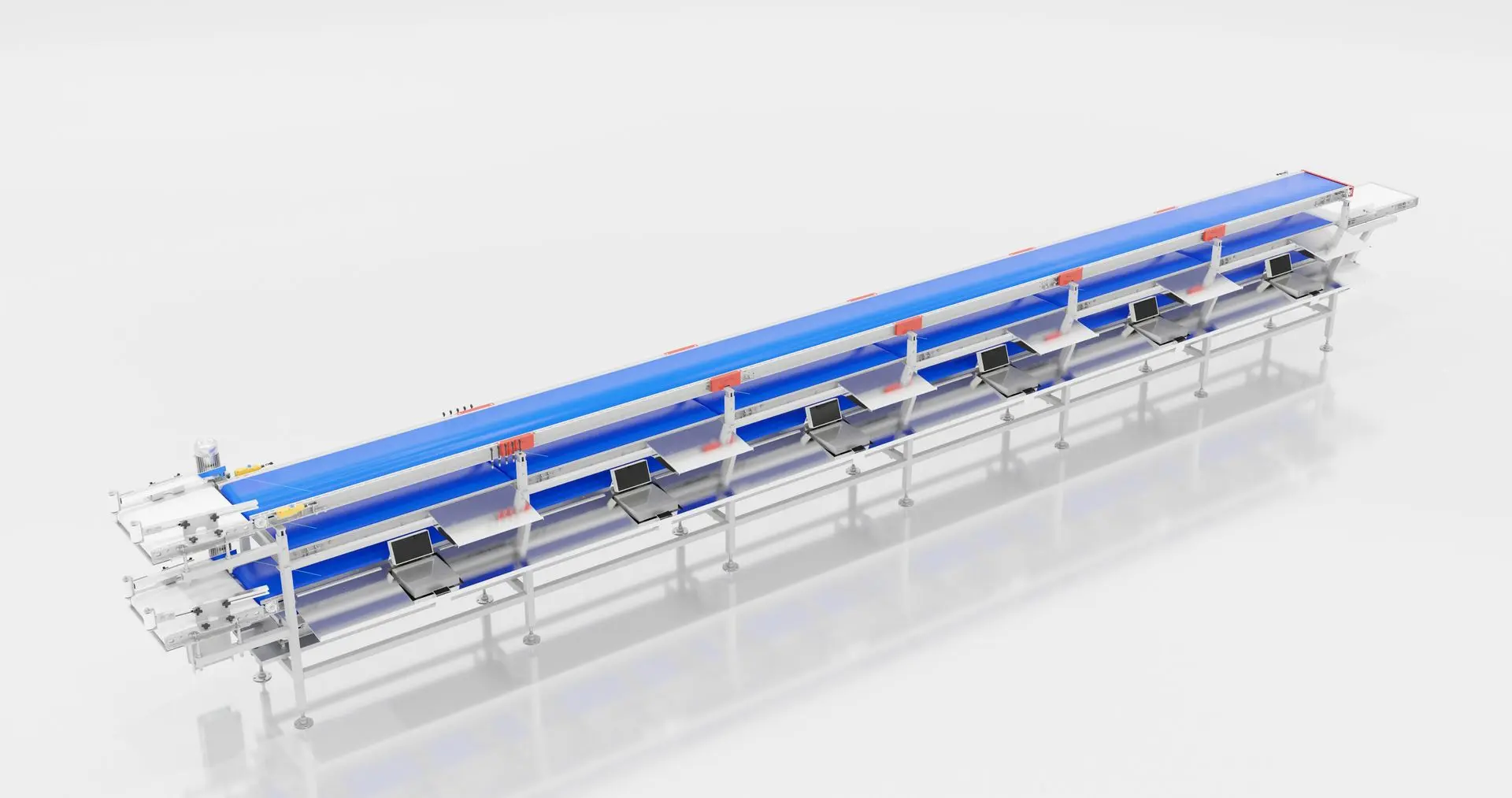

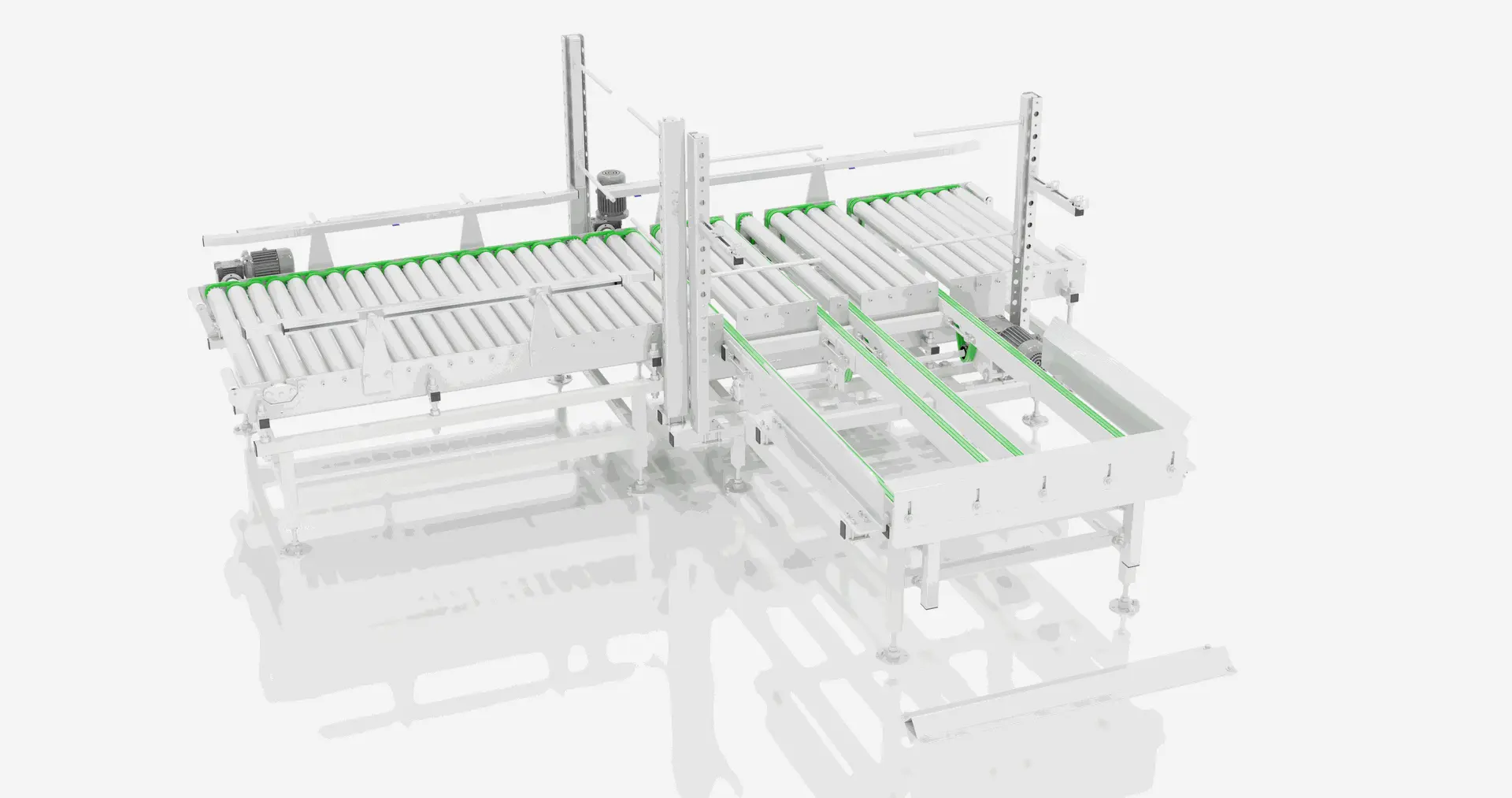

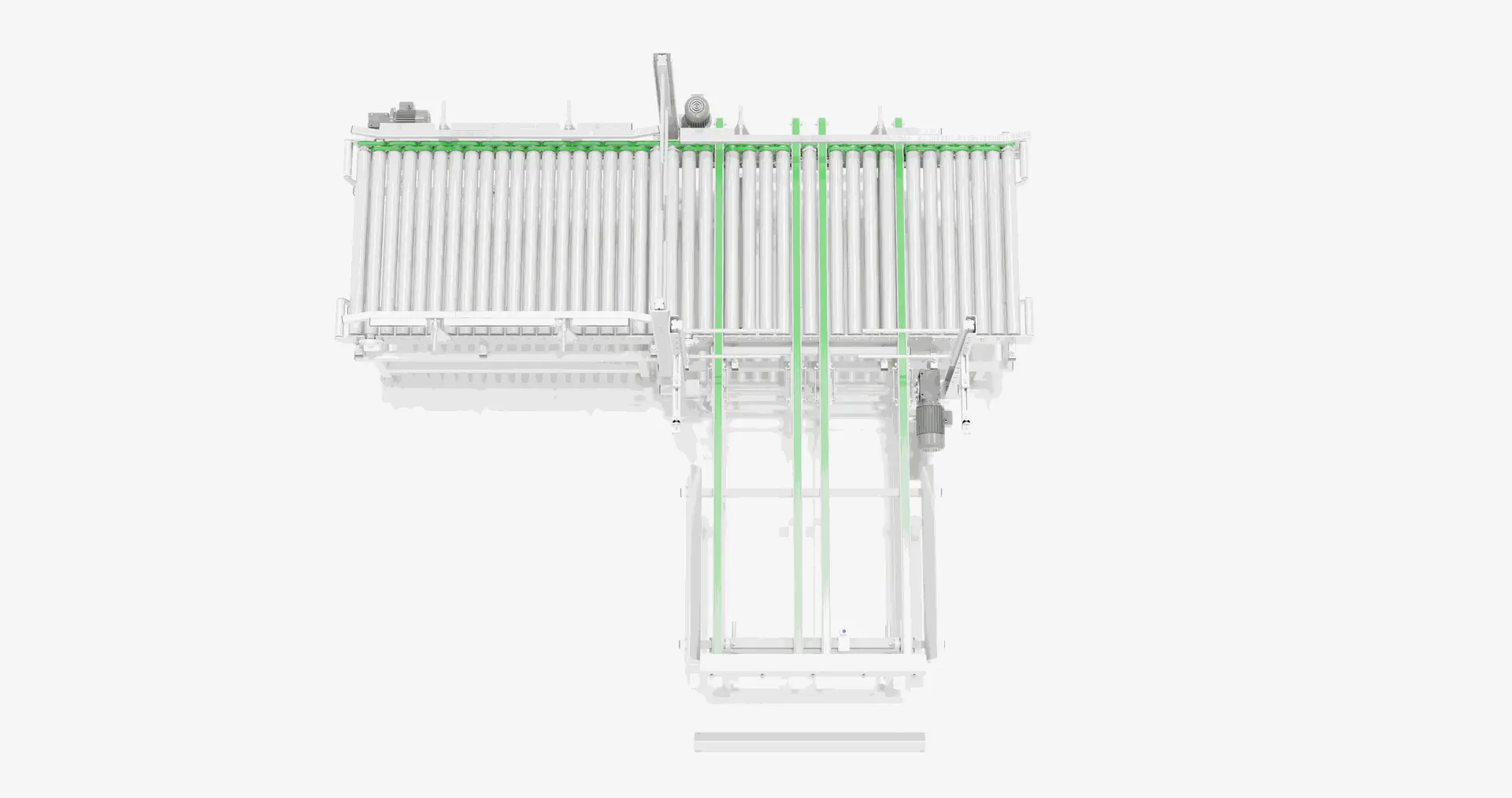

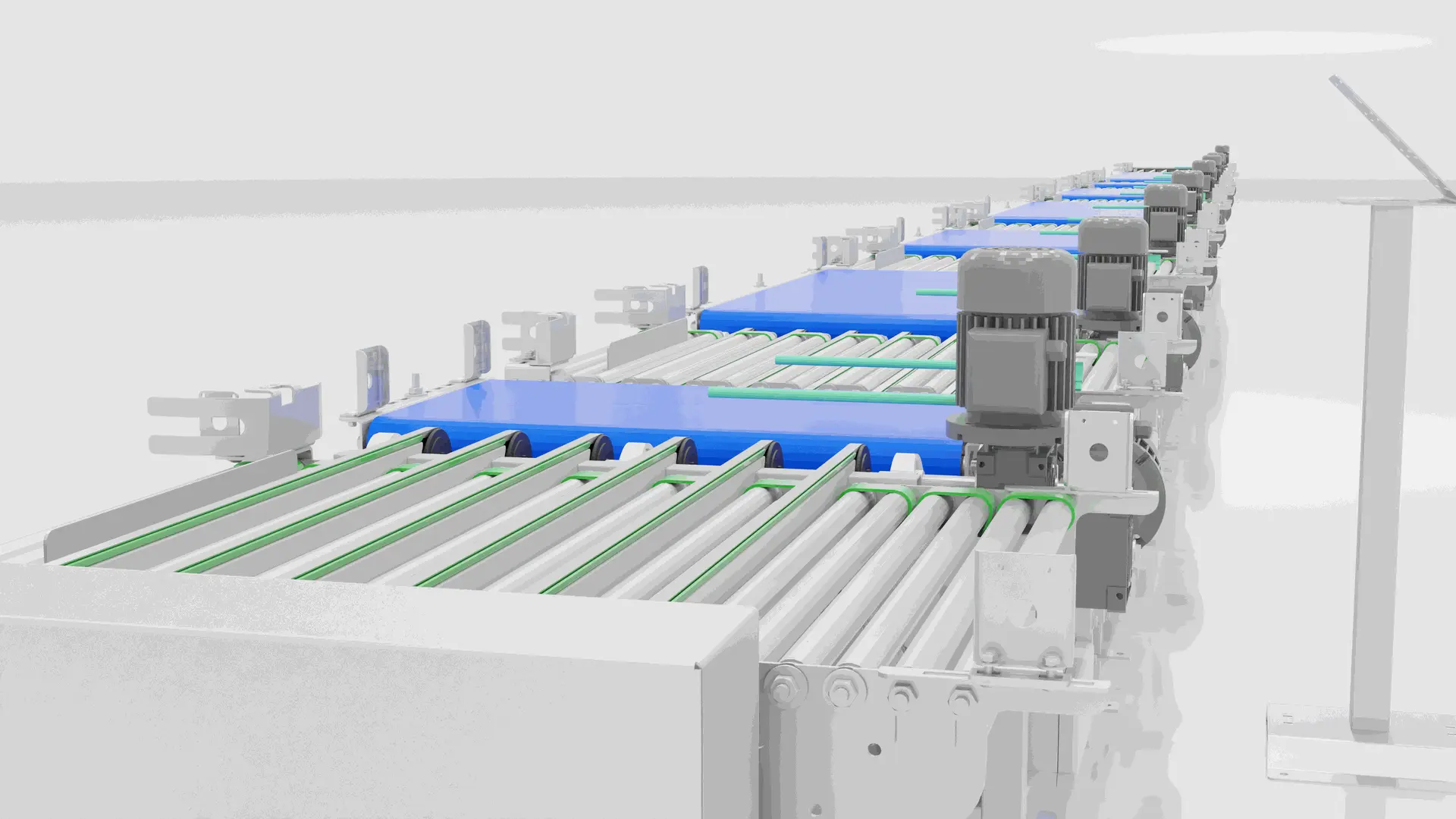

BOXSORTER

Box collector

Box or package collector.

Customized transport system for receiving and distributing boxes from multiple inputs to multiple outputs.

BOXSORTER

Box collector

Box or package collector.

Customized transport system for receiving and distributing boxes from multiple inputs to multiple outputs.

BOXSORTER

Box collector

Box or package collector.

Customized transport system for receiving and distributing boxes from multiple inputs to multiple outputs.

BOXSORTER

Box collector

Box or package collector.

Customized transport system for receiving and distributing boxes from multiple inputs to multiple outputs.

BOXSORTER

Box collector

Box or package collector.

Customized transport system for receiving and distributing boxes from multiple inputs to multiple outputs.

| Reference Product | Boxes made of any material |

| Cadences |

Consult. |

| Configuration | Modular and expandable system. |

|

HMI

|

Entry and destination point configuration software |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Modularity

- Allows you to configure the line based on modules, as well as plan for future expansions.

Comfort and ergonomics:

- Silent load management system.

Automatic product identification:

- QR.

- RFID.

- Artificial Vision

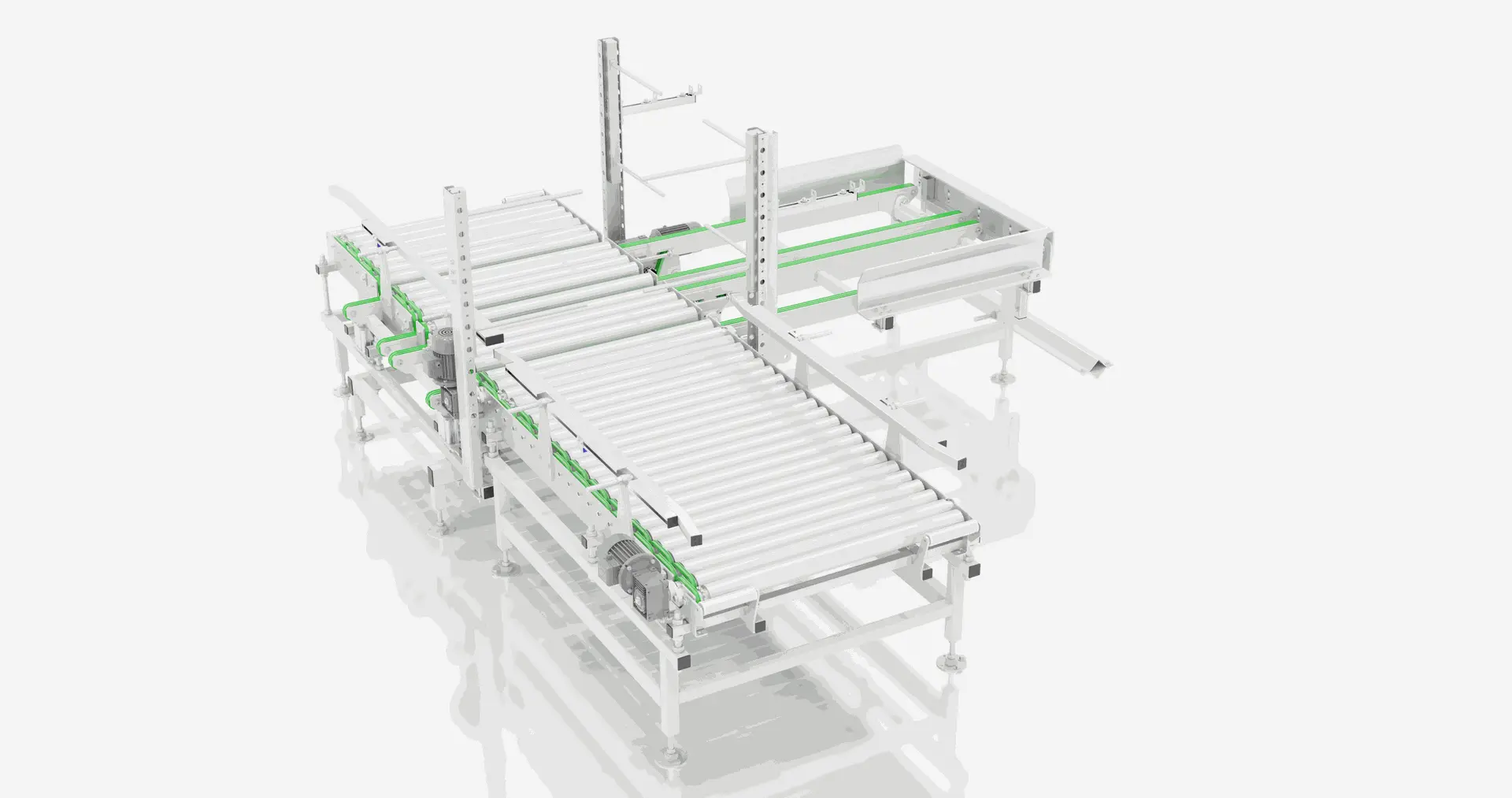

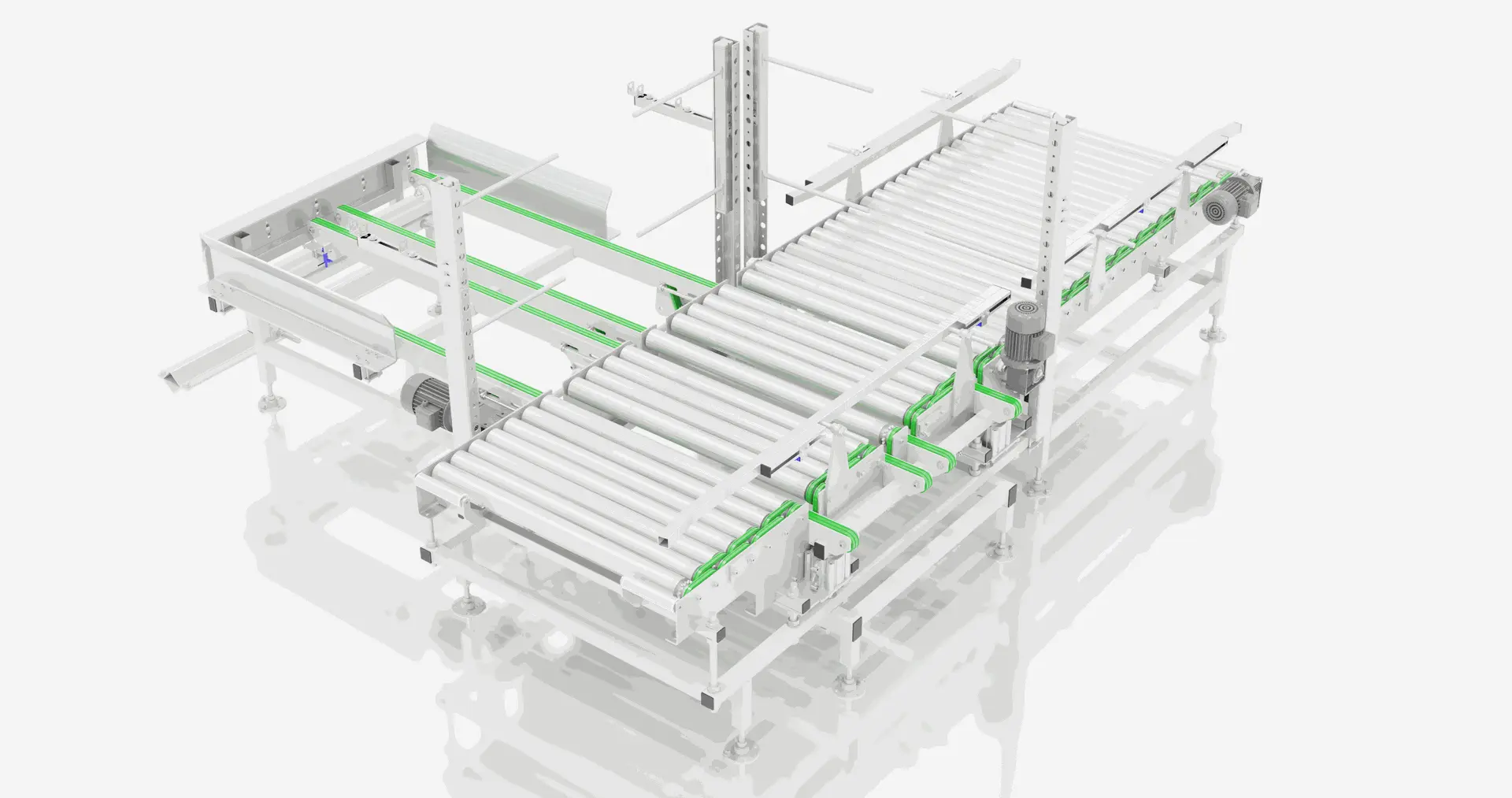

TRANSFER W 2000

Cargo transfer line

Transfer system for moving heavy loads between different work lines.

TRANSFER W 2000

Cargo transfer line

Transfer system for moving heavy loads between different work lines.

TRANSFER W 2000

Cargo transfer line

Transfer system for moving heavy loads between different work lines.

TRANSFER W 2000

Cargo transfer line

Transfer system for moving heavy loads between different work lines.

TRANSFER W 2000

Cargo transfer line

Transfer system for moving heavy loads between different work lines.

TRANSFER W 2000

Cargo transfer line

Transfer system for moving heavy loads between different work lines.

TRANSFER W 2000

Cargo transfer line

Transfer system for moving heavy loads between different work lines.

TRANSFER W 2000

Cargo transfer line

Transfer system for moving heavy loads between different work lines.

| Reference Product | Pallets with loads up to 2000 kg. |

| Configuration |

Modular and expandable system. |

| HMI | Software for configuring pickup and drop-off points. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Handling:

- Compact machine that can be easily integrated into the production line

Regulations:

- Ability to work in food environments.

- Data recording in file.

- Batch control.

- Statistics.

- LAN Connectivity.

- Integration: SCADA, ERP.

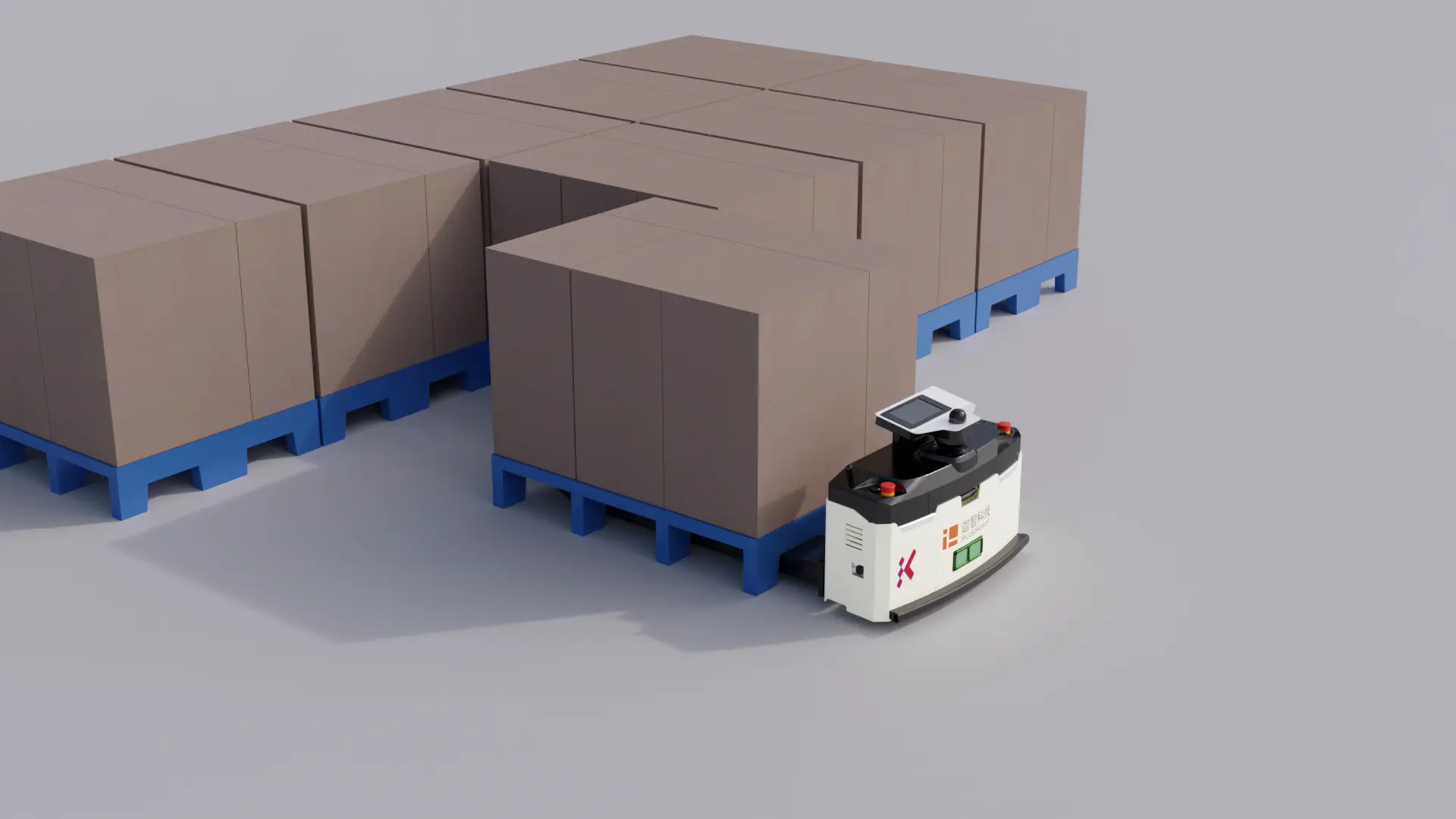

KMR FORKLIFT

Fork-type AMR robot

Autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

KMR FORKLIFT

Fork-type AMR robot

Autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

KMR FORKLIFT

Fork-type AMR robot

Autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

KMR FORKLIFT

Fork-type AMR robot

Autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

KMR FORKLIFT

Fork-type AMR robot

Autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

KMR FORKLIFT

Fork-type AMR robot

Autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

| Load |

Up to 1,400 kg |

| Reference product |

Pallets or any similar platform |

| Positioning accuracy | <10 mm |

|

Maximum speed |

1,5 m/s |

| Default navigation |

Laser |

Autonomy | Up to 6 hours |

Possible angle of inclination | Up to 5% |

Flexibility:

- Unlike AGVs with fixed routes, Keeltek's KMRs instantly adapt to changes in the plant layout.

Intuitive integration:

- Its user-friendly control software enables rapid programming, outperforming other AMRs that require specialized personnel, which streamlines implementation in packaging operations.

Enhanced security:

- Equipped with advanced sensors and obstacle detection systems, AKMRs ensure safe operations alongside human workers, outperforming AGVs in collaborative environments.

Cost efficiency:

- They offer a fast return on investment (ROI), estimated at 4-6 months, thanks to reduced labor costs and optimized flows, with more economical maintenance than AGVs because they do not depend on fixed infrastructure.

Effortless scalability

- KMRs allow units to be added or tasks to be reconfigured easily, surpassing other AMRs and AGVs in flexibility to grow with production needs.

Accuracy in repetitive tasks

- They optimize the transport of any product with high precision, reducing errors compared to manual solutions or less adaptable AGVs.

- 3D navigation camera.

- Self-loading.

- Fleet integration (expandable).

- Customized software and fleet management.

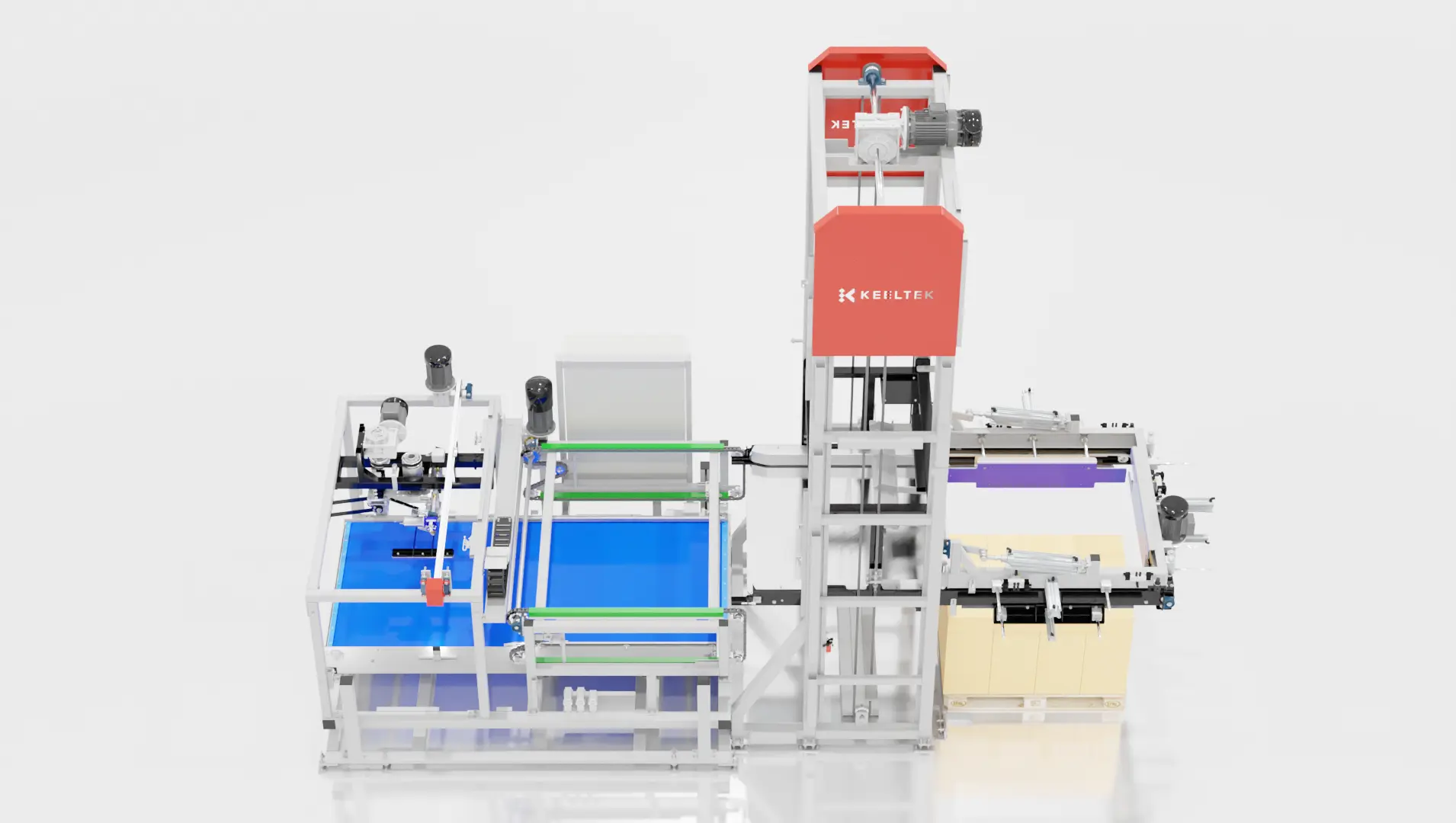

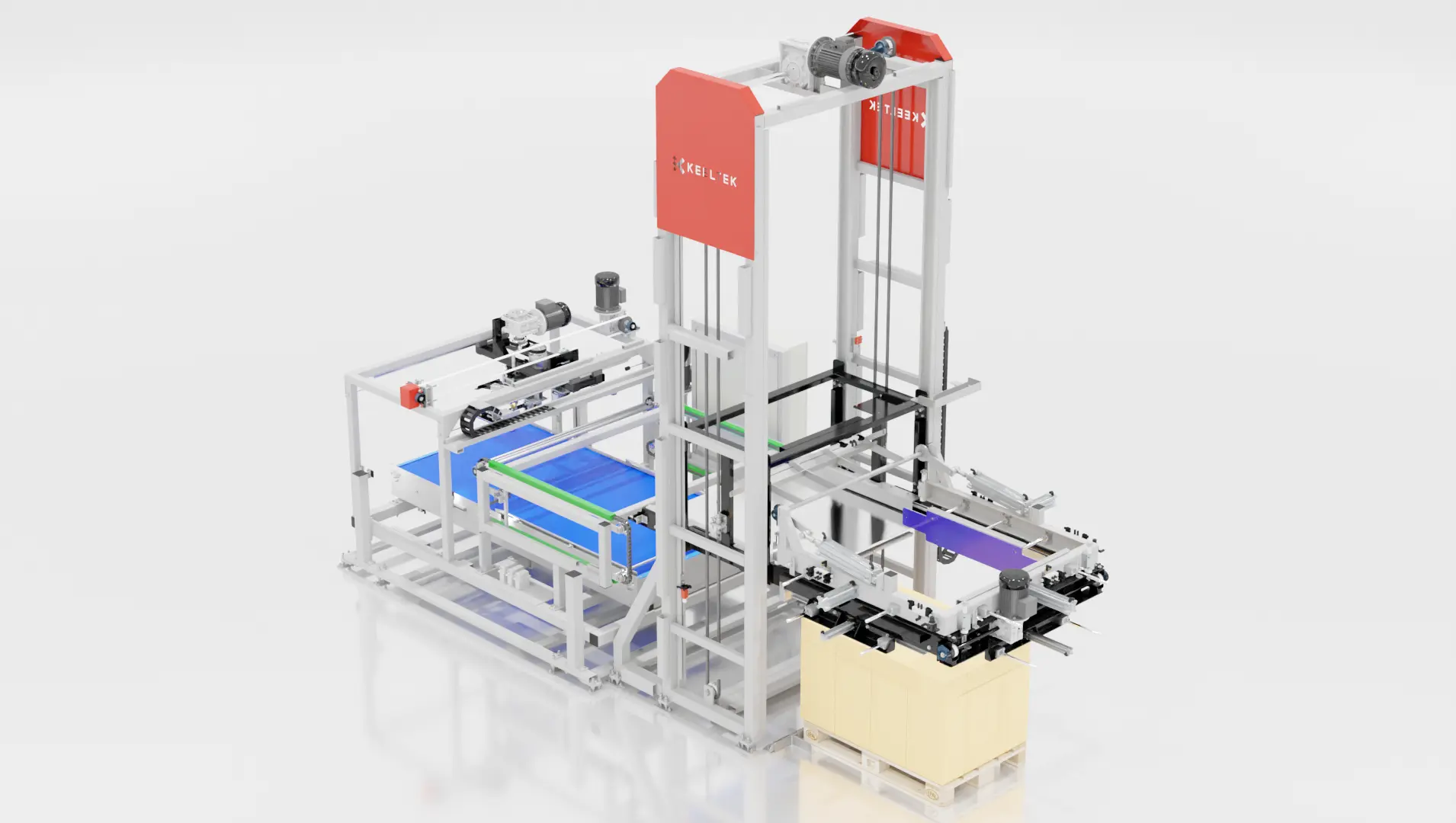

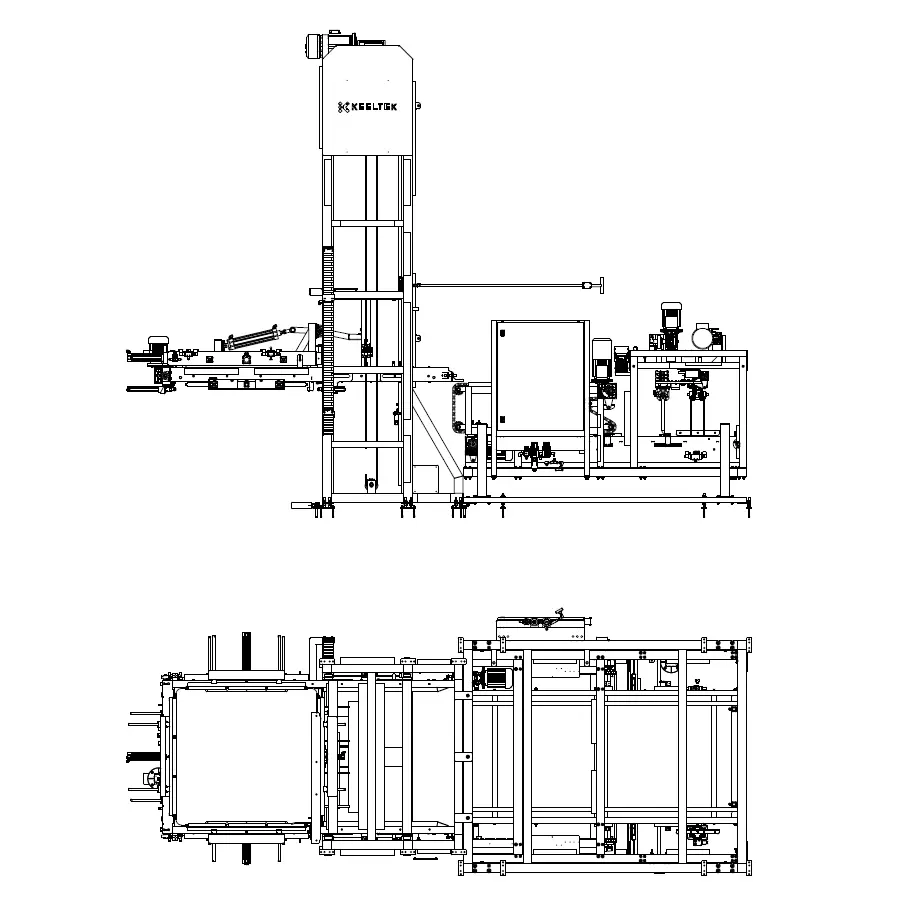

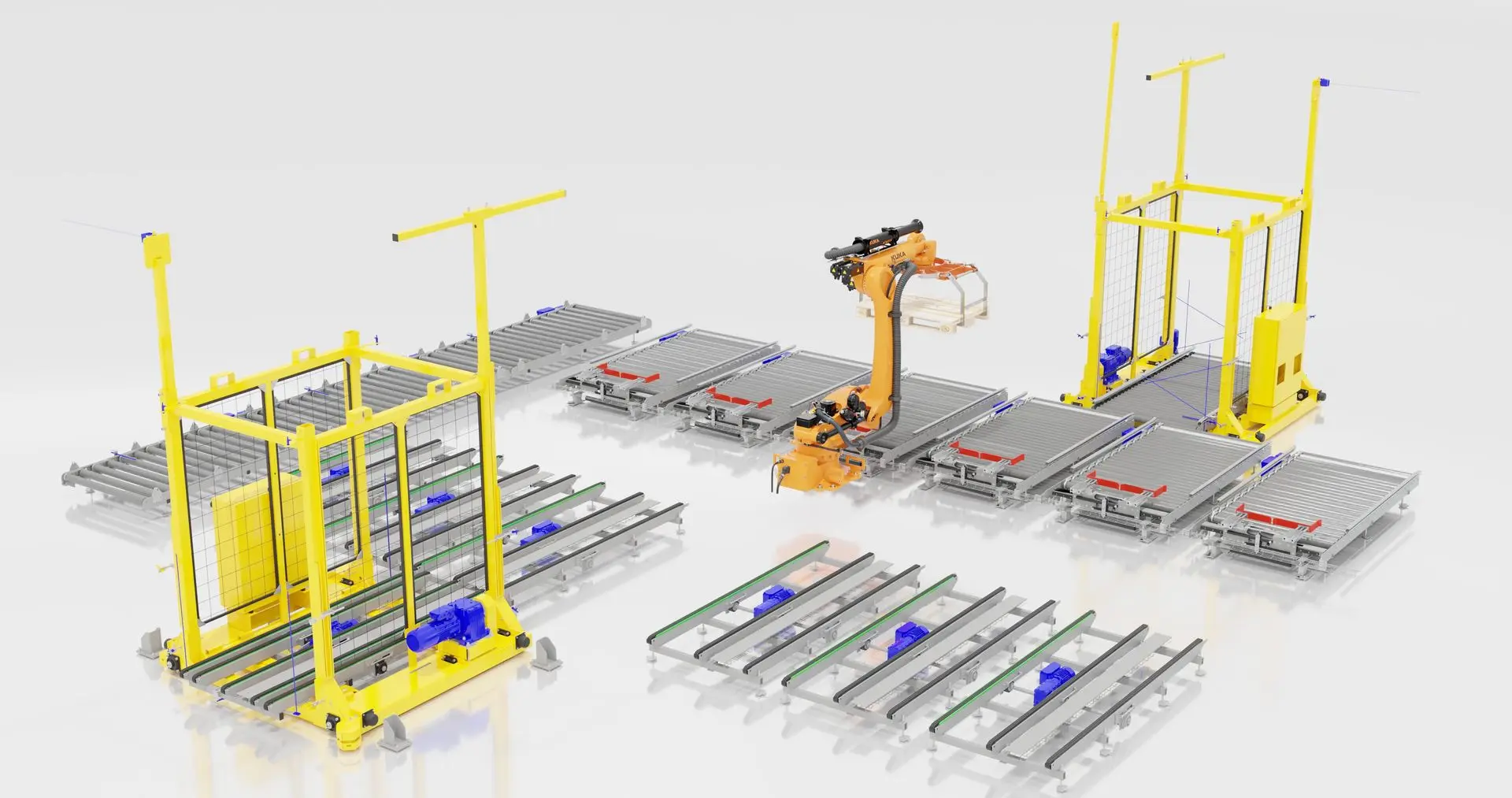

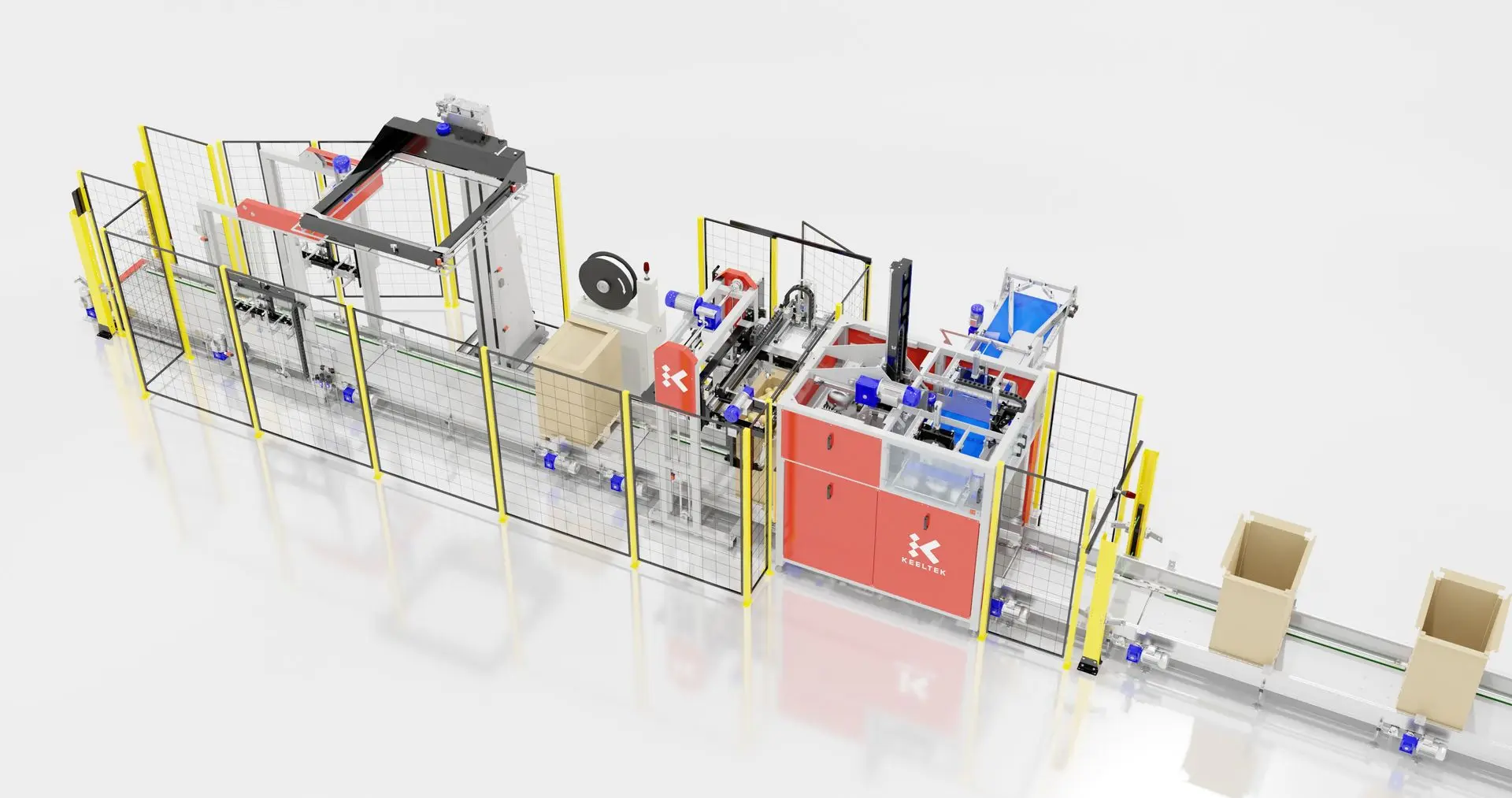

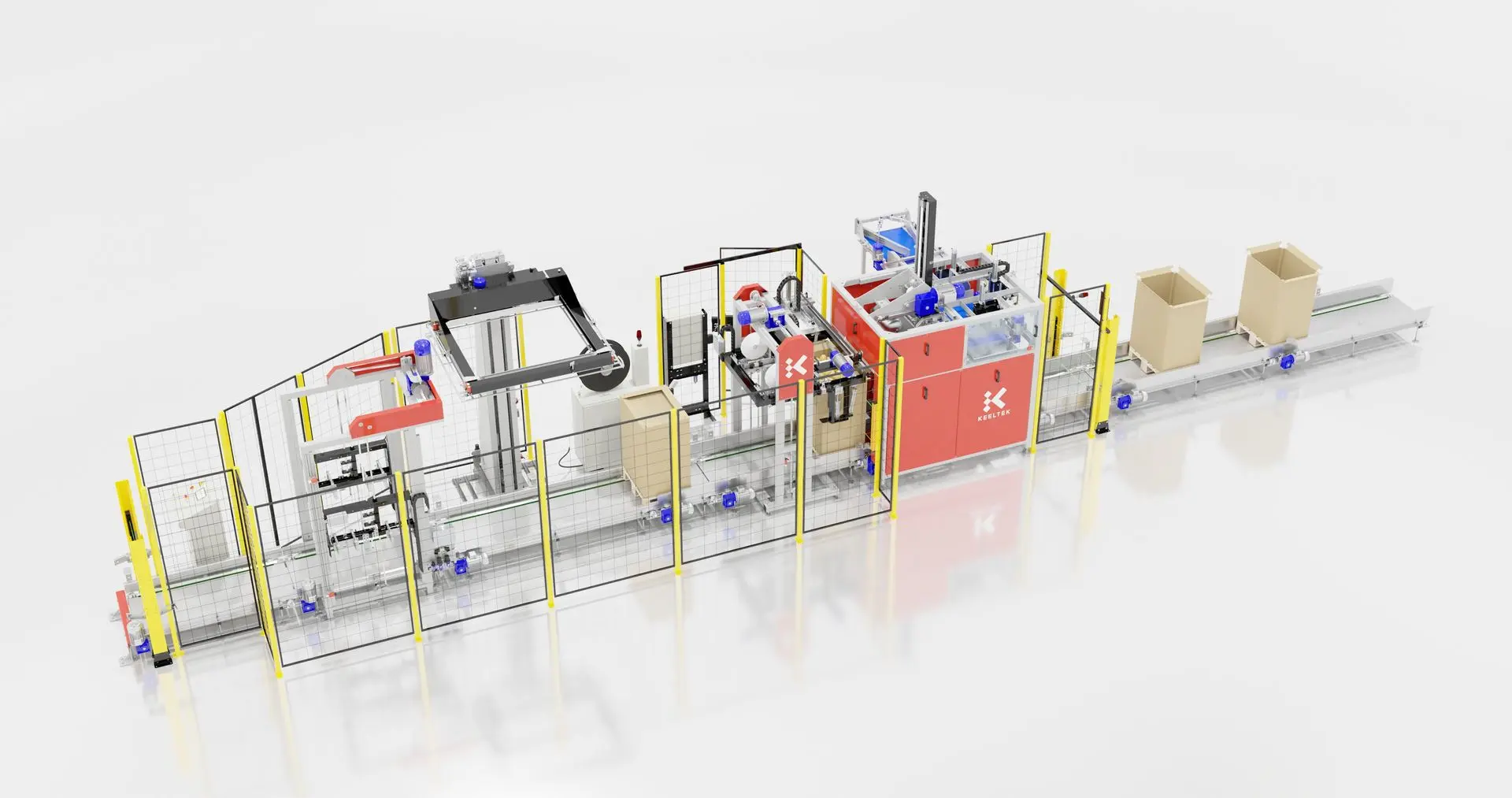

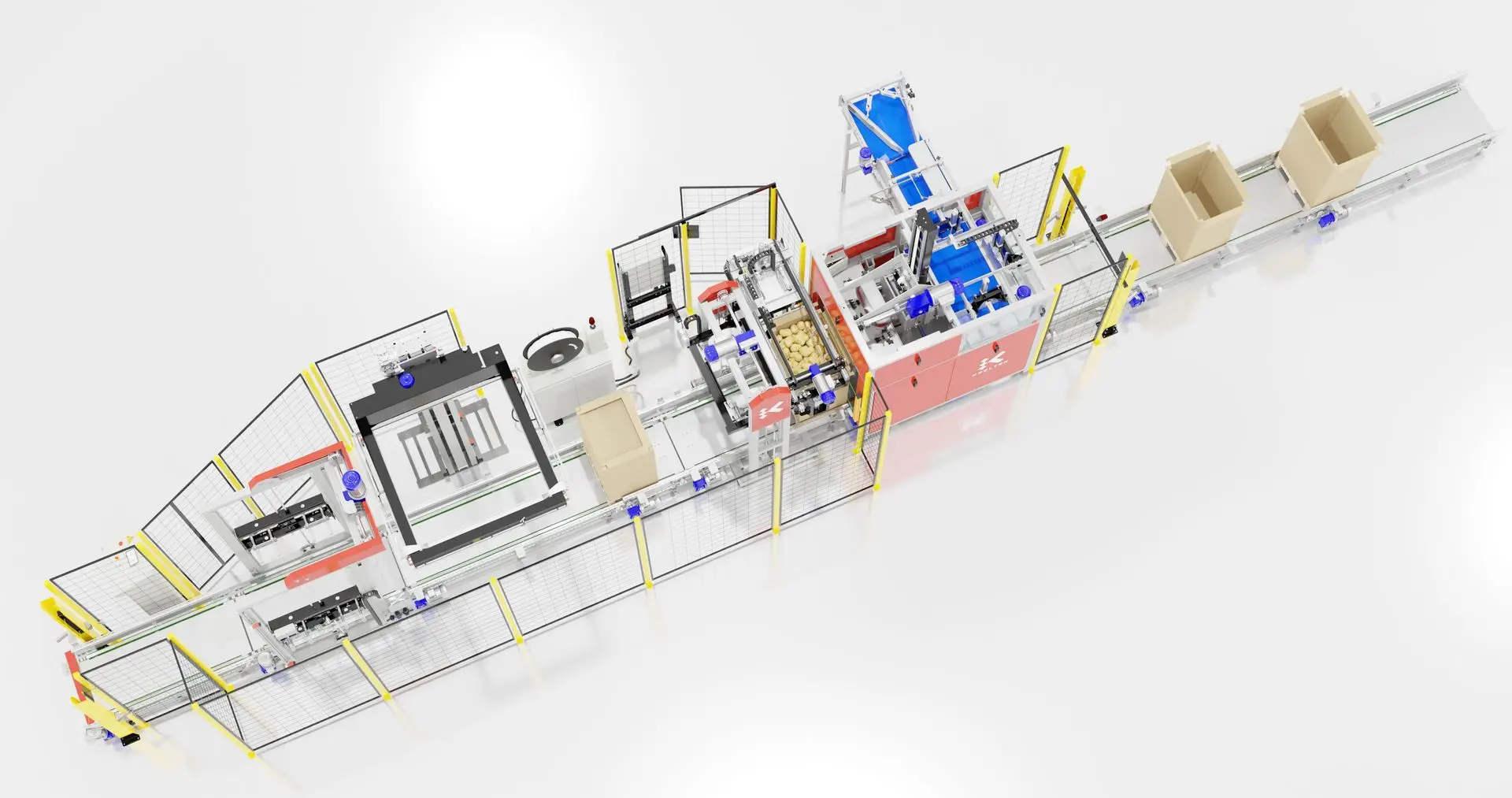

OVERPACK PLUS

Line for overwrapping, sealing, strapping, and stacking boxes

Complete packaging line where the product comes off the line in sack or bag format and the box is filled automatically. The box is completed by placing and sealing the flap, and then the boxes are grouped together for strapping and final palletizing.

OVERPACK PLUS

Line for overwrapping, sealing, strapping, and stacking boxes

Complete packaging line where the product comes off the line in sack or bag format and the box is filled automatically. The box is completed by placing and sealing the flap, and then the boxes are grouped together for strapping and final palletizing.

OVERPACK PLUS

Line for overwrapping, sealing, strapping, and stacking boxes

Complete packaging line where the product comes off the line in sack or bag format and the box is filled automatically. The box is completed by placing and sealing the flap, and then the boxes are grouped together for strapping and final palletizing.

OVERPACK PLUS

Line for overwrapping, sealing, strapping, and stacking boxes

Complete packaging line where the product comes off the line in sack or bag format and the box is filled automatically. The box is completed by placing and sealing the flap, and then the boxes are grouped together for strapping and final palletizing.

OVERPACK PLUS

Line for overwrapping, sealing, strapping, and stacking boxes

Complete packaging line where the product comes off the line in sack or bag format and the box is filled automatically. The box is completed by placing and sealing the flap, and then the boxes are grouped together for strapping and final palletizing.

| Reference Product | Any that needs to be fitted. |

| Box Size |

Consult. |

| Output product | Full pallet. |

| Maximum cadence | Consult. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed using laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Possibility of using different boxers depending on the size of the box.

- Optional strapping.

Request information instantly

Fill out the form below and provide detailed information about your preferred model.

All this without any obligation.

Explora ahora al detalle nuestras soluciones para el sector de la Alimentación y Bebidas.